Are you ready to take your woodworking and DIY projects to the next level? Whether you're a seasoned craftsman or just starting your DIY journey, the right tool can make all the difference. Sanders are the unsung heroes of the workshop, and with a staggering variety available, it's crucial to choose the perfect one for your specific project. In this comprehensive guide, I'll unveil 20 different types of sanders, each designed to tackle unique tasks and surfaces. I've covered you, from smoothing rough edges to a flawless finish. Say goodbye to guesswork and hello to precision – let's dive into the world of sanding and elevate your craftsmanship to new heights!

A sander is a force instrument utilized to even the exteriors by scratched stains with a sanding paper. Sanders got a method to append the sandpaper and a component to move it quickly confined free space with aims to hand-hold that or fix it to a worktable. Carpentry sanders, generally controlled by electrically, and those utilized in auto-body fix work by packed air. There are different sorts of sanders for multiple purposes. Multi-reason power apparatuses and electric drills may have sander connections. There is a wide range of sanders, each with a different reason. You may know about these sorts, you utilized some, and some might be unknown for you.

Beneath, you'll locate the most widely recognized sorts of sanders recorded, what they utilize, and how they work.

Unlike other regular apparatuses, sanders frequently have different provincial epithets, making it increasingly hard to make sense of what you're working.

It ought to additionally notice that most of the sanders use sanding paper or equal. These beginning at 60 coarseness and become better as the coarseness tally increases. Entering from 60 and stirring your method up to better scraps will provide you an abundant, evener finished result.

What Kind of Sander Do I Need?

If you need a sanding project done, the kind of sander you'll need depends on what aspect of the item(s) being sanded - for example are they high or low to the ground?

Sanders range from small handheld units that can be moved in any direction to large belt sanders. The use of each one, as well as its cost and time necessary for usage, is dependent on whether it's a paint job or just minor touch-ups that need attention, such if a table needs has a few scratches removed. Mind these factors when looking into different versions so that not only do they suit your current needs but also your possible future needs while still keeping things within an affordable price range.

Watch the video to find out which type of sander to use for each job.

Types of Sander

Sanders are available in different designs and have varying applications. There is a sander out there for everyone, so it's important to make sure you pick the one that suits your needs best!

Air-Powered (Pneumatic) Sander: A Versatile Tool for Smoother Surfaces

An air-powered (pneumatic) sander is a handheld power tool used in various industries and woodworking applications for sanding and finishing surfaces.

Unlike electric sanders, powered by electricity, air-powered sanders operate using compressed air as their energy source.

These tools are designed to provide a consistent and controlled sanding action, making them ideal for achieving smooth and uniform surfaces.

How It Works

At its core, an air-powered sander harnesses the power of compressed air to drive a sanding mechanism. Here's a simplified breakdown of how it operates:

- Air Compressor: The heart of the system is an air compressor, which generates compressed air at high pressure. This air is usually supplied through a hose.

- Sanding Mechanism: The compressed air is directed to the sander's motor, which powers the sanding pad or belt. The speed and force of the sanding action can often be adjusted to suit the specific task.

- Sanding Disc/Belt: The sander is equipped with a sanding disc or belt that rotates or oscillates, depending on the type of sander. This abrasive surface is what removes material from the workpiece.

- Sanding Material: Various sanding materials, such as sandpaper, abrasive discs, or belts, can be attached to the sander, allowing for customization based on the desired finish.

Pros:

- Powerful Performance: Pneumatic sanders are known for their high power-to-weight ratio, making them exceptionally efficient at material removal. They excel in smoothing and shaping tasks.

- Continuous Operation: Unlike electric sanders, pneumatic sanders can operate continuously without overheating, making them suitable for extended use.

- Precision and Control: These sanders offer precise control over sanding speed and pressure, allowing for fine detailing and finishing.

- Versatility: Air-powered sanders come in various types, including orbital, random orbital, and belt sanders, making them adaptable to various projects.

- Reduced Vibration: Pneumatic sanders produce less vibration than their electric counterparts, reducing user fatigue and enhancing comfort during prolonged use.

- Dust Collection: Many pneumatic sanders have dust collection systems, keeping the work area cleaner and healthier.

- Durability: These tools are known for their durability and longevity, making them a sound investment for professionals.

Cons:

- Compressor Required: To operate a pneumatic sander, you need access to an air compressor, which can be an additional expense if you don't already have one.

- Noise: While they produce less vibration, pneumatic sanders can still be noisy, requiring hearing protection in noisy work environments.

- Portability: The need for an air compressor and hose can limit the portability of pneumatic sanders compared to cordless electric alternatives.

Best Suited Projects:

Air-powered sanders are highly versatile and can be used in a variety of projects, including:

- Woodworking: Smoothing rough wood surfaces, shaping edges, and finishing wooden pieces.

- Metalworking: Removing rust, paint, or welds and preparing metal surfaces for painting or welding.

- Automotive Refinishing: Sanding car bodies, priming, or finishing automotive surfaces.

- Furniture Restoration: Restoring antique furniture by removing old finishes and smoothing surfaces.

- Drywall Finishing: Achieving a smooth finish on drywall joints and seams.

Who Benefits from Owning a Pneumatic Sander:

- Professional Woodworkers: Cabinet makers, carpenters, and furniture makers can benefit from the precision and power of pneumatic sanders.

- Auto Body Shops: Pneumatic sanders are indispensable for auto body repair and refinishing.

- Metal Fabricators: Professionals in metal fabrication, welding, or painting can achieve cleaner, more polished results.

- DIY Enthusiasts: Hobbyists and DIYers looking for a reliable, versatile, and durable sanding tool for various home improvement projects.

In short, the air-powered sander is a valuable addition to any workshop, offering power, precision, and versatility. While it requires an air compressor and maybe a bit less portable, its ability to tackle a wide range of projects efficiently and with finesse makes it an excellent choice for professionals and dedicated DIYers.

Battery-Powered (Cordless) Sander: A Versatile Woodworking Tool

A Battery-Powered (Cordless) Sander is a handheld power tool designed for sanding various surfaces, such as wood, metal, or plastic, without needing a direct electrical connection.

It is equipped with a rechargeable battery pack that provides the necessary power to operate the sander, eliminating the need for a cord or electrical outlet.

How it Works:

A battery-powered sander operates on the same basic principles as its corded counterpart but with the added advantage of mobility and freedom from power outlets. Here's a simplified breakdown of its functioning:

- Battery Power: The heart of this sander is its rechargeable lithium-ion battery. This battery provides the necessary electrical energy to power the motor.

- Motor: The motor is responsible for generating the motion needed for sanding. Depending on the sander's design, it drives the sanding pad or belt.

- Sanding Pad/Belt: The sanding surface, whether a pad or a belt, is attached to the motor shaft. When the motor runs, it causes the sanding surface to move in a circular or linear motion, depending on the sander type.

- Dust Collection: Many cordless sanders have a dust collection system to clean the work area and minimize exposure to fine dust particles. The dust is typically collected in a detachable container or bag.

- Trigger/Controls: Users can start and control the sander's speed using a trigger or a switch, allowing for precise adjustments during operation.

Pros:

- Portability: The absence of a cord allows users to work freely without being tethered to an electrical outlet. This is especially advantageous in outdoor or remote locations.

- Convenience: Quick and easy setup, with no need to unravel and manage cords. It's a time-saver for small to medium-sized tasks.

- Less Noise and Vibration: Battery-powered sanders are generally quieter and produce less vibration than corded models, making them more comfortable for extended periods.

- Versatility: They come in various types, including orbital, random orbital, and belt sanders, catering to different sanding needs.

- Battery Life: Modern lithium-ion batteries offer impressive runtimes, often sufficient for an entire project on a single charge.

- Dust Control: Many models feature effective dust collection systems, enhancing air quality and reducing cleanup time.

- Safety: No cords to trip over or accidentally damage, reducing the risk of accidents in the workspace.

Cons:

- Limited Runtime: While battery life has improved significantly, it may still be insufficient for large, time-consuming projects requiring frequent recharges.

- Initial Cost: Cordless sanders tend to be more expensive upfront due to the inclusion of a rechargeable battery and associated electronics.

- Weight: Battery packs can add weight to the sander, slightly heavier than corded counterparts.

Projects Best Suited for Cordless Sanders:

- Furniture Restoration: Sanding tables, chairs, cabinets, and other furniture is more convenient with a cordless sander, especially when moving between pieces.

- Outdoor Projects: Refinishing decks, fences, or wooden outdoor structures benefit from the portability of cordless sanders.

- Trim Work: Precise sanding of moldings, trim, and baseboards is easier with a cordless sander, as there are no cords to hinder movement.

- Art and Craft Projects: For hobbyists and DIY enthusiasts working on smaller projects like wooden signs or sculptures, cordless sanders offer ease of use.

Who Should Get Benefits from Buying a Cordless Sander:

- DIY Enthusiasts: Hobbyists and individuals who frequently undertake home improvement projects will appreciate the convenience and versatility of a cordless sander.

- Woodworkers: Professionals and amateurs working with wood, whether for fine furniture or general carpentry, can greatly benefit from these sanders' freedom of movement and precision.

- Contractors: Construction professionals working in various locations will find cordless sanders invaluable for on-site sanding tasks.

- Outdoor Enthusiasts: People who enjoy woodworking in outdoor settings, such as building a gazebo or refinishing a porch, can capitalize on the portability of cordless sanders.

In short, the battery-powered sander is a game-changer for woodworkers, DIY enthusiasts, and professionals alike. Its portability, convenience, and versatility make it a must-have tool for sanding projects, offering a perfect blend of mobility and power.

Belt Sander: A Power Tool for Precision and Efficiency

A belt sander is a power tool designed for rapidly and efficiently sanding or smoothing various surfaces, typically wood, metal, or plastic. A motor-driven abrasive sanding belt moves continuously over two cylindrical drums, creating a rotating sanding surface.

Belt sanders are commonly used in woodworking and metalworking applications to remove material quickly, shape and smooth edges, or prepare surfaces for finishing.

How It Works

A belt sander features an abrasive sanding belt that revolves around two cylindrical drums. One drum is located at the front, while the other is at the rear. When the tool is powered on, the sanding belt moves rapidly, allowing the user to press the surface being worked on against it.

As the abrasive belt rotates, it removes material from the surface smoothly and consistently. The operator can adjust the speed and pressure, enabling precise control over the sanding process.

Pros:

- Efficiency: Belt sanders are incredibly efficient at material removal. Their rapid abrasive belt movement lets you quickly smooth or shape large surfaces.

- Versatility: They can handle various materials, from wood to metal and even plastics, making them suitable for various projects.

- Precision: Belt sanders offer high precision, allowing for controlled and uniform material removal, making them ideal for achieving smooth, flat surfaces.

- Fast Stock Removal: When you need to remove a significant amount of material, such as when refinishing a tabletop, a belt sander is a tool for the job.

- Ease of Use: Belt sanders are relatively easy to operate, even for beginners, and their simplicity makes them accessible to a wide range of users.

- Effective in Stripping Paint: They excel at stripping old paint or finishes from surfaces, saving time and effort compared to manual methods.

- Adaptability: Many belt sanders come with adjustable features, including speed settings and tilt angles, allowing you to adapt the tool to your needs.

Cons:

- Aggressive Material Removal: While its efficiency is advantageous, the belt sander's aggressiveness can also be a drawback if not used carefully, as it can quickly remove more material than intended.

- Limited for Detailed Work: Due to their speed and size, belt sanders are not well-suited for intricate or small-scale projects that require delicate sanding.

- Risk of Overheating: Extended use of a belt sander can cause overheating, potentially damaging the tool or the material being worked on. Adequate breaks are necessary to prevent this issue.

Best Suited Projects:

Belt sanders are ideal for projects that involve significant material removal and surface leveling. Some common applications include:

- Floor Sanding: Refinishing hardwood floors to a smooth, uniform surface.

- Large Woodworking Projects: Smoothing and shaping tabletops, doors, and cabinets.

- Deck Refinishing: Stripping old paint or stain from wooden decks.

- Metalworking: Removing burrs or polishing metal surfaces.

- Do-It-Yourself Home Renovations: Preparing surfaces for painting or refinishing.

Who Should Get Benefits:

- Woodworkers: Professionals and hobbyists who work with wood will find belt sanders indispensable for their projects, whether furniture making, cabinetry, or flooring.

- DIY Enthusiasts: Home improvement enthusiasts can achieve professional-quality results in their renovation projects with the help of a belt sander.

- Metalworkers: For tasks like deburring and polishing metal components, metalworkers will appreciate the efficiency and precision of a belt sander.

- Contractors: Contractors involved in construction, remodeling, or restoration projects can save time and effort using belt sanders.

In short, the belt sander is a powerful tool that offers efficient material removal, versatility, and precision for a wide range of projects. While it excels in many areas, users should exercise caution to avoid its aggressive nature and overheating issues.

Individuals engaged in woodworking, DIY projects, metalworking, or construction will find this tool to be a valuable addition to their toolkit, helping them achieve smoother, more professional results efficiently.

Benchtop Belt and Disc Sander: Versatile Sanding Powerhouse

A Benchtop Belt and Disc Sander is a versatile and essential tool for woodworking enthusiasts, DIYers, and professionals. This tool combines a belt sander's efficiency and a disc sander's precision, making it a valuable addition to any workshop.

How it Works:

The Benchtop Belt and Disc Sander consist of two primary components: a sanding belt and a sanding disc. The sanding belt is mounted vertically and functions like a conveyor belt, continuously moving around two drums.

This allows for efficient material removal and is excellent for flat surfaces and straight edges. On the other hand, the sanding disc, mounted horizontally, provides precise sanding for curves, angles, and intricate details.

The operator can adjust the angle and height of the sanding table, allowing for customization to suit the specific project. To operate the sander, you simply turn it on, feed your workpiece into the sanding belt or disc, and let the machine do the hard work.

Pros:

- Versatility: One of the most significant advantages of the Benchtop Belt and Disc Sander is its versatility. It can handle various sanding tasks, from heavy stock removal to fine-finishing work. This makes it suitable for various woodworking projects.

- Efficiency: The continuous movement of the sanding belt, coupled with its high-speed operation, allows for quick material removal, saving time and effort.

- Precision: The sanding disc provides precise control, making it ideal for delicate projects that require accurate sanding, such as smoothing curved edges or rounding corners.

- Two-in-One Design: You get the benefits of both a belt sander and a disc sander in one compact machine, saving space in your workshop.

- Dust Collection: Many models come with built-in dust collection systems, which help keep your workspace clean and reduce airborne dust, contributing to a healthier working environment.

- Ease of Use: Operating this sander is relatively straightforward, even for beginners. It requires minimal setup and adjustment.

- Longevity: With proper maintenance and care, a quality Benchtop Belt and Disc Sander can last for years, making it a cost-effective investment in the long run.

Cons:

- Price: Quality Benchtop Belt and Disc Sanders can be relatively expensive compared to other sanding tools. However, their versatility justifies the cost for serious woodworkers.

- Size and Weight: While compact compared to industrial-sized sanders, these benchtop models can still take up a significant amount of space in a small workshop. They can also be heavy and challenging to move around.

- Noise and Dust: Like most power tools, Benchtop Belt and Disc Sanders can be noisy, and the dust generated during sanding can be a nuisance if not adequately managed.

Best Suited Projects:

This sander is well-suited for various projects, including:

- Furniture Making: It excels at smoothing and shaping wood for furniture construction.

- Cabinet Making: Ideal for preparing cabinet components and fine-tuning joints.

- Edge Sanding: Perfect for refining the edges of boards and panels.

- Curved Work: The disc sander is excellent for projects with curved or irregular shapes.

- DIY Home Improvement: Suitable for sanding doors, windows, and wooden floors.

Who Should Get Benefits:

- Woodworkers: Whether a hobbyist or a professional woodworker, a Benchtop Belt and Disc Sander is a valuable addition to your arsenal.

- DIY Enthusiasts: Home improvement enthusiasts can use this sander for a wide range of projects around the house.

In short, these sanders are commonly used in woodworking and metalworking workshops, as they make tasks like smoothing rough-cut lumber, removing paint or rust, and shaping workpieces more manageable and precise.

Proper usage and safety precautions are essential when operating a Benchtop Belt and Disc Sander to prevent accidents and achieve the desired results in various woodworking and metalworking projects.

Bowl Sander: A Perfect Blend of Precision and Versatility

In woodworking, achieving a flawless finish is often the hallmark of craftsmanship. One tool that has gained popularity for its ability to deliver impeccable results is the bowl sander.

This versatile sanding tool is designed to streamline the process of sanding curved surfaces, making it an invaluable addition to any woodworking workshop.

How the Bowl Sander Works:

A bowl sander, also known as a spindle sander or oscillating spindle sander, is engineered to sand concave and convex curves precisely. It consists of a sanding drum attached to a spindle, which rotates as it oscillates up and down. Here's how it operates:

- Sanding Drum: The heart of the bowl sander is the sanding drum. This cylindrical component is wrapped with sandpaper, which comes in various grits for different levels of abrasion.

- Oscillation: When the machine is powered on, the sanding drum rotates and moves up and down in a gentle oscillating motion. This dual action allows for even and consistent sanding across curved surfaces.

- Precision Control: Most bowl sanders feature adjustable tables and tilting mechanisms that enable woodworkers to customize the angle and depth of sanding, ensuring precise results.

Pros:

- Effortless Curved Surface Sanding: Bowl sanders excel at sanding curved surfaces, making them perfect for tasks like shaping chair legs, smoothing concave table edges, or rounding off corners.

- Precision and Consistency: The oscillating motion of the sanding drum ensures even sanding, eliminating the risk of uneven or over-sanded areas.

- Time Efficiency: Unlike manual sanding, bowl sanders save significant time, making them invaluable for production work or large projects.

- Versatility: Many bowl sanders come with interchangeable spindles and various drum sizes, allowing woodworkers to tackle a wide range of tasks and work with different grits of sandpaper.

- Dust Collection: Most modern bowl sanders come equipped with efficient dust collection systems, keeping the workspace clean and protecting the user's health.

Cons:

- Specialized Use: While the bowl sander is excellent for curved surfaces, it may not be the most versatile tool for flat or angular sanding tasks.

- Price: Quality bowl sanders can be relatively expensive, which might deter hobbyists or occasional woodworkers.

Ideal Projects for Bowl Sanders:

- Furniture Making: Crafting curved chair legs, table aprons, or cabriole legs is much easier with a bowl sander.

- Cabinetry: Sanding the edges of curved cabinet doors or creating decorative moldings becomes a breeze.

- Instrument Making: Luthiers and instrument makers use bowl sanders to shape the intricate curves of musical instruments like violins and guitars.

- Decorative Woodworking: Woodworkers specializing in intricate designs and decorative elements benefit from the precision of a bowl sander.

- Restoration Work: A bowl sander can help maintain the original shape and finish when restoring antique furniture or wooden artifacts with curved components.

Who Benefits from Owning a Bowl Sander:

- Professional Woodworkers: Craftsmen and woodworkers who frequently work on curved surfaces will find a bowl sander indispensable for ensuring quality finishes efficiently.

- Advanced Hobbyists: Enthusiastic hobbyists and DIYers who take their woodworking seriously can invest in a bowl sander to elevate the quality of their projects.

In short, the bowl sander is a powerful tool that brings precision and efficiency to the sanding of curved surfaces. Its ability to produce flawless finishes and save valuable time makes it an asset for professionals and dedicated hobbyists.

While it may not be suitable for all sanding tasks, its advantages in terms of versatility and precision make it a valuable addition to any woodworking workshop.

Buffer Sander (Floor Sander): A Versatile Sanding Solution

A buffer sander, commonly known as a floor sander, is a versatile tool used in woodworking and flooring projects. It is essential in achieving smooth and polished surfaces, whether refinishing a hardwood floor, preparing a deck for staining, or smoothing out rough wooden surfaces.

How it Works:

A buffer sander, or floor buffer, operates through a circular motion, typically with a circular sanding pad attached to the bottom. It is designed to move in a controlled, oscillating pattern to ensure even sanding and minimize the risk of gouging or creating uneven surfaces. Depending on the project's requirements, the sanding pad can be fitted with various abrasive materials, such as sandpaper or screens.

When turned on, the buffer sander's motor powers the rotation of the sanding pad, which, when pressed against the work surface, effectively sands away imperfections, old finishes, and unevenness. The operator guides the sander across the surface, ensuring consistent results.

Pros:

- Efficient Material Removal: Buffer sanders are incredibly efficient at removing old finishes, stains, and imperfections from wooden surfaces. Their high-speed rotation and abrasive pads make quick work of tough sanding tasks.

- Versatility: These sanders suit various projects, including hardwood floor refinishing, deck sanding, and automotive bodywork. With the right abrasive attachments, they can tackle different materials.

- Uniform Surface: Buffer sanders excel at providing a smooth and even surface. They are ideal for achieving a consistent finish, ensuring no patches or irregularities remain.

- Ease of Use: Compared to other sanding tools, buffer sanders are relatively easy to operate. Their oscillating motion makes them more forgiving, reducing the risk of over-sanding and creating divots.

- Time and Labor Savings: A buffer sander can significantly reduce the time and physical effort required for sanding projects. Its efficiency means quicker results, saving both time and money.

Cons:

- Learning Curve: While buffer sanders are user-friendly, there is still a learning curve, especially for beginners. Achieving a consistent finish requires some practice and finesse.

- Dust Management: Like most sanding tools, buffer sanders produce substantial dust. Proper dust extraction or ventilation is essential to maintain a clean and healthy working environment.

Projects Best Suited for a Buffer Sander:

- Hardwood Floor Refinishing: Buffer sanders are the go-to tool for refinishing hardwood floors, as they can efficiently remove old finishes and blemishes.

- Deck Sanding: Whether you're prepping a wooden deck for staining or removing weathered layers, buffer sanders make the job faster and more manageable.

- Woodworking: Woodworkers can use buffer sanders to refine wooden surfaces, achieving a polished finish on projects like cabinets, tables, and doors.

Who Should Benefit from Buying a Buffer Sander:

- DIY Enthusiasts: Homeowners who enjoy tackling renovation and improvement projects around the house can benefit from owning a buffer sander. It simplifies many sanding tasks, making DIY projects more manageable.

- Professional Contractors: Flooring contractors, carpenters, and those in the construction industry can greatly improve their efficiency and quality of work by incorporating buffer sanders into their tool arsenal.

- Woodworking Artisans: Furniture makers and artisans who work with wood can achieve smoother finishes in their creations, enhancing their products' overall quality and aesthetics.

In short, the buffer sander, or floor sander, is a valuable tool that simplifies sanding tasks, making them more efficient and delivering consistent, polished results.

While there is a slight learning curve and the need for proper dust management, its versatility makes it an excellent investment for DIY enthusiasts, professionals, and woodworking artisans looking to enhance their craft and achieve beautiful, uniform surfaces in their projects.

Detail Sander (Corner Sander): A Versatile Tool for Precision Sanding

The Detail Sander, often referred to as a Corner Sander, is a versatile and compact power tool designed for precision sanding in hard-to-reach areas and tight corners. It is a valuable addition to any DIY enthusiast or professional woodworker's toolbox, offering several advantages while having a couple of limitations.

How the Detail Sander Works:

The Detail Sander operates by oscillating a sanding pad or triangular-shaped sandpaper at high speeds. This rapid back-and-forth motion allows for precise and controlled sanding in areas that are challenging to access with larger sanding tools. Depending on the type of sandpaper attached, it can be used for wood and non-wood surfaces, such as metal or plastic.

Pros:

- Precision Sanding: The primary advantage of a Detail Sander is its ability to access tight corners, edges, and intricate patterns that larger sanders cannot reach. This precision makes it perfect for finishing work and refinishing furniture.

- Ease of Use: Detail Sanders are typically lightweight and easy to handle, making them user-friendly even for those with limited experience. Their compact size allows for comfortable maneuvering and reduces user fatigue.

- Versatility: These sanders can accommodate various sandpaper grits, enabling you to perform tasks ranging from gentle surface smoothing to aggressive material removal. They are adaptable to a wide range of projects.

- Dust Collection: Many Detail Sanders come equipped with dust collection systems that help keep the workspace cleaner and protect your health by minimizing exposure to airborne particles.

- Cost-Efficiency: Detail Sanders are usually more affordable than larger sanders, making them an excellent choice for DIY enthusiasts and hobbyists on a budget.

Cons:

- Limited Surface Area: Due to its small sanding pad or sandpaper shape, the detail Sander is unsuitable for large surface sanding tasks. It's less efficient for tasks like floor sanding or large tabletops.

- Vibrations and Noise: These sanders can produce considerable vibrations and noise during operation, which may be uncomfortable for extended use. It's advisable to wear hearing protection and take breaks as needed.

Projects Best Suited for a Detail Sander:

- Furniture Refinishing: Detail Sanders is ideal for restoring and refinishing wooden furniture, including chairs, tables, and cabinets. They can effectively remove old paint, varnish, or imperfections in intricate designs.

- Trim and Molding: When painting or refinishing trim work and molding, the detail Sander ensures a smooth finish in tight spaces.

- Craftsmanship: For intricate woodworking projects, such as crafting wooden toys or intricate scrollwork, the detail Sander excels in smoothing and shaping.

- Home Renovations: Detail Sanders are valuable tools during home renovations, especially when sanding in corners, around door frames, or between floorboards.

- Auto Bodywork: Detail Sanders can prep surfaces for painting or remove rust and imperfections in tight spaces in automotive repair.

Who Should Benefit from Buying a Detail Sander:

- DIY Enthusiasts: Hobbyists and homeowners who enjoy DIY projects will find a Detail Sander an invaluable addition to their tool collection, particularly if they often work on furniture or home improvements.

- Woodworkers: Professional woodworkers and carpenters will appreciate the precision and versatility of the Detail Sander when working on custom furniture or cabinetry.

- Painters and Finishers: Professionals in the painting and finishing industry can use the Detail Sander to prepare surfaces for paint or varnish, achieving a flawless final product.

- Restoration Specialists: Individuals involved in restoring antiques or vintage furniture will find the detail Sander to be an indispensable tool for preserving and enhancing the beauty of older pieces.

- Automotive Enthusiasts: Auto body shops and car restoration hobbyists can benefit from the Detail Sander when refinishing or repairing vehicles, especially for intricate details and tight spaces.

In short, the detail Sander is a valuable tool for many users with its ability to provide precision sanding in tight spaces, ease of use, versatility, dust collection, and cost-efficiency.

While it may have limitations regarding surface area coverage and noise, its advantages make it a must-have for anyone involved in woodworking, DIY projects, finishing work, or restoration tasks.

Whether you're a professional or a hobbyist, a Detail Sander can help you achieve superior results in projects requiring meticulous attention to detail.

Disc Sander: A Versatile Woodworking Tool

A disc sander is a versatile and essential tool in the arsenal of woodworkers and DIY enthusiasts. It is commonly used for shaping, smoothing, and finishing wood surfaces.

This tool consists of a rotating abrasive disc mounted on a motor-driven spindle. As the disc spins, it provides a rapid and effective way to remove material and achieve a polished finish on various woodworking projects. Here's how it works, its pros and cons, ideal projects, and target users.

How it Works:

A disc sander typically consists of the following key components:

- Motor: The heart of the disc sander, the motor provides the necessary power to drive the abrasive disc.

- Abrasive Disc: This is the main working part of the sander, usually made of sandpaper or abrasive material. It attaches to the spindle and rotates when the machine is turned on.

- Table: The table supports the workpiece and can often be tilted to various angles for specific sanding tasks.

- Fence: Some disc sanders have a fence that helps maintain a consistent angle while sanding edges and corners.

- Dust Collection: Many modern disc sanders include a dust collection system to minimize the mess and keep the workspace clean.

To use a disc sander, you place the workpiece on the table and turn on the machine. By gently guiding the wood against the spinning abrasive disc, you can remove material and shape the wood as needed. The table can be adjusted to achieve precise angles, making it suitable for various sanding tasks.

Pros:

- Efficiency: Disc sanders are incredibly efficient at material removal and surface smoothing. They can save a significant amount of time compared to hand sanding.

- Precision: These sanders allow for precise shaping and smoothing, making them ideal for woodworking projects that require accuracy.

- Versatility: You can use a disc sander for various tasks, including sanding curved and flat surfaces, beveling edges, and removing imperfections.

- Dust Control: Many disc sanders come equipped with effective dust collection systems, contributing to a cleaner and healthier work environment.

- Time-saving: The speed and power of disc sanders make them ideal for projects involving large surfaces or bulk material removal.

Cons:

- Safety Concerns: Disc sanders can be dangerous if not used properly. The fast-spinning disc can cause injuries if it comes into contact with fingers or loose clothing.

- Limited Application: While versatile, disc sanders are unsuitable for all sanding tasks. They may not be the best choice for fine, delicate work that requires a gentle touch.

Best Suited Projects:

Disc sanders are well-suited for a range of woodworking projects, including:

- Cabinet Making: They are ideal for smoothing cabinet doors, panels, and edges.

- Furniture Building: Disc sanders help shape and refine furniture components like tabletops, legs, and armrests.

- Joinery: For tasks such as beveling and sanding tenons and mortises.

- Curve Sanding: They excel at sanding curved edges, making them great for arches or round tabletop projects.

- Woodturning: Disc sanders can be used to shape and refine wooden turning projects, such as bowls and spindles.

Who Should Consider Buying a Disc Sander:

- Woodworkers: Whether professional or hobbyist, a disc sander can greatly enhance your efficiency and precision in various woodworking projects.

- DIY Enthusiasts: DIYers who frequently work with wood and enjoy crafting furniture, cabinets, or other wooden items will benefit from the versatility of a disc sander.

- Professional Craftsmen: Professional artisans involved in cabinetry, joinery, and furniture making can streamline their work processes with a disc sander.

- Restoration Specialists: Those involved in restoring and refinishing antique furniture or wooden fixtures will find a disc sander invaluable for removing old finishes and imperfections.

In short, a disc sander is a powerful tool that offers woodworking and DIY enthusiasts efficiency, precision, and versatility. While it has safety considerations and limitations, it is an essential addition to any woodworking shop or toolbox for those prioritizing speed and accuracy in their projects.

Drum Sander: A Powerful Tool for Precision Sanding

A drum sander is a versatile woodworking machine used to achieve smooth and even surfaces on various types of wood and other materials. It is an essential tool in the arsenal of both amateur and professional woodworkers, as it can significantly streamline the sanding process and deliver high-quality results.

How a Drum Sander Works:

A drum sander consists of several key components, including a cylindrical drum covered with abrasive sandpaper, a conveyor belt, and a motor. Here's how it works:

- Material Feeding: The user places the material to be sanded onto the conveyor belt, which transports it towards the rotating drum.

- Sanding Drum: The drum, typically made of metal or hard rubber, contains sandpaper. As the drum rotates, it comes into contact with the material, effectively sanding the surface.

- Pressure Adjustment: Most drum sanders allow users to adjust the pressure applied to the material, ensuring uniform sanding across the entire surface.

- Fine-tuning: Users can adjust the drum's height to control the sanding's depth, allowing for precision sanding based on the project's requirements.

- Dust Collection: Drum sanders often include a dust collection system to minimize airborne dust and maintain a clean work environment.

Pros:

- Efficient Material Removal: Drum sanders excel at quickly and efficiently removing material, saving time compared to manual sanding.

- Precision and Consistency: They produce consistently smooth surfaces, eliminating the risk of uneven or wavy finishes.

- Versatile: Drum sanders can handle various materials, including wood, plywood, MDF, and even some metals, making them versatile for different projects.

- Time Savings: For large projects or when working with thick material, drum sanders significantly reduce sanding time, increasing productivity.

- Professional Finish: Drum sanders provide a professional-level finish that can be challenging to achieve with other sanding methods.

Cons:

- High Initial Cost: Quality drum sanders can be expensive, which might deter hobbyists or those on a tight budget.

- Limited to Flat Surfaces: Drum sanders are primarily designed for flat surfaces, making them less suitable for intricate or curved woodworking projects.

Projects Best Suited for Drum Sanders:

Drum sanders are particularly well-suited for the following projects:

- Large Furniture Pieces: Tables, cabinets, and dressers benefit from the speed and precision of a drum sander for achieving smooth surfaces.

- Flooring: Sanding hardwood floors becomes more manageable with a drum sander, ensuring a consistent and professional finish.

- Door Panels: For flat door panels, drum sanders provide efficient sanding, resulting in a polished look.

- Plywood and Veneer: When working with plywood or veneer, drum sanders can level surfaces and eliminate imperfections.

- Thickness Planing: Drum sanders can serve as a thickness planer, allowing you to accurately reduce the thickness of lumber.

Who Should Consider Buying a Drum Sander:

- Professional Woodworkers: Cabinet makers, furniture builders, and flooring professionals can significantly benefit from the efficiency and quality of drum sanders in their daily work.

- Serious Hobbyists: Enthusiastic woodworkers who tackle complex and sizable projects will appreciate the time savings and precision a drum sander offers.

- Home Renovators: Individuals engaged in home improvement projects, like refinishing floors or restoring antique furniture, will find drum sanders invaluable for achieving professional results.

In short, a drum sander is a powerful tool that streamlines the sanding process, delivering smooth and consistent surfaces.

While it may have a higher initial cost and limitations on curved surfaces, its efficiency, precision, and versatility make it an essential addition to the toolkit of woodworking professionals, dedicated hobbyists, and home renovators alike.

Whether you're working on furniture, flooring, or other wood-based projects, a drum sander can elevate the quality and efficiency of your work.

Drywall Sander: A Powerful Tool for Smooth Surfaces

A drywall sander, or a drywall pole sander or sanding machine, is an essential tool for professionals and DIY enthusiasts in home improvement or construction projects involving drywall installation and finishing. This tool is designed to streamline the sanding process, making it faster and more efficient.

How It Works:

A drywall sander is a specialized power tool that automates the sanding process for drywall surfaces. It has a long, extendable handle allows users to reach high ceilings and walls comfortably. A sanding head with an attached sandpaper disc is at the pole's end.

The user simply maneuvers the sander across the drywall surface, and the sandpaper rotates, smoothing out imperfections and creating an even texture.

Most drywall sanders come with a vacuum attachment or a dust collection system. This feature is crucial as it minimizes the generation of fine dust particles during sanding, ensuring a cleaner and healthier working environment.

Pros:

- Time-Saving: Drywall sanders significantly reduce manual labor and speed up the sanding process, making it possible to complete large projects in less time.

- Precision: These sanders offer precise control, allowing users to achieve a smooth, even finish with fewer imperfections.

- Less Fatigue: The ergonomic design of drywall sanders, with adjustable handles and lightweight construction, reduces user fatigue during extended sanding sessions.

- Dust Control: The built-in dust collection system or vacuum attachment captures most of the dust generated during sanding, creating a cleaner workspace and promoting better air quality.

- Versatility: Drywall sanders are not limited to drywall; they can be used for other applications like smoothing ceilings, wooden surfaces, or even automotive bodywork.

Cons:

- Cost: Quality drywall sanders can be expensive, which might deter some DIY enthusiasts with limited budgets.

- Learning Curve: Using a drywall sander effectively requires practice and skill, especially for beginners. Improper technique can result in uneven surfaces.

Projects Best Suited for Drywall Sander:

Drywall sanders are exceptionally useful for a variety of projects, including:

- Drywall Installation: Sanding down seams and imperfections in newly installed drywall is the primary purpose of these sanders.

- Drywall Repair: When patching or repairing damaged drywall, a sander can help blend the patched area seamlessly with the existing wall.

- Ceiling Finishing: Smoothing and preparing ceilings for painting or finishing can be challenging without a drywall sander due to the overhead work involved.

- Woodworking: Drywall sanders can be used on wood surfaces, particularly for fine sanding and finishing of furniture, cabinets, or wooden floors.

Beneficiaries of Drywall Sanders:

Several groups can benefit from owning a drywall sander:

- Professional Contractors: Drywall contractors, painters, and construction professionals can greatly enhance their work efficiency and quality with a drywall sander.

- DIY Enthusiasts: Homeowners engaged in DIY home improvement projects, such as basement renovations, room makeovers, or ceiling repairs, can achieve professional-looking results with the help of a drywall sander.

- Renovation and Restoration Companies: Companies specializing in renovating older buildings or restoring historic properties can save time and labor costs using drywall sanders for surface preparation.

- Woodworking Hobbyists: Woodworking enthusiasts can use drywall sanders for fine sanding and finishing wooden projects, ensuring a smooth and polished surface.

In short, a drywall sander is a versatile and time-saving tool that offers numerous benefits for many projects. While it may come with a learning curve and initial investment, the advantages of faster, more precise sanding and improved dust control make it a valuable addition to any toolkit.

Whether you're a professional contractor or a DIY enthusiast, a drywall sander can help you achieve smoother, more professional project results.

File Sander (Finger Sander): A Handy Tool for Precision Sanding

The File Sander, often referred to as a Finger Sander, is a specialized sanding tool designed to offer precision and control in woodworking and various DIY projects.

This compact and versatile tool rotates a small abrasive belt or wheel, making it ideal for reaching tight spots and shaping intricate details.

How the File Sander Works:

The File Sander operates on a simple yet effective principle. It comprises a narrow, elongated housing with a motor and a sanding belt or wheel.

The user holds the tool with a comfortable grip while the sanding element rotates at high speeds. The sanding surface can be a narrow belt or a cylindrical drum covered in abrasive material. As the user applies the File Sander to the workpiece, it perfectly smooths and shapes the material.

Pros:

- Precision Sanding: The File Sander's compact size and narrow sanding belt or wheel allow precise control, making it perfect for detailed work and fine finishing.

- Versatility: It can handle a variety of materials, including wood, plastic, metal, and even curved or irregular surfaces, making it a versatile tool in any workshop.

- Accessibility: Its slim profile allows it to reach into tight spaces and corners that are challenging to access with larger sanders, ensuring thorough and even sanding.

- Reduced Fatigue: The ergonomic design and lightweight construction minimize user fatigue during prolonged use, increasing efficiency and comfort.

- Time-Saving: The File Sander's efficiency in quickly removing material and shaping surfaces can save time on projects, making it a valuable addition to any DIY enthusiast's arsenal.

Cons:

- Limited Surface Area: The File Sander is unsuitable for large surface sanding tasks due to its narrow sanding belt or wheel. It excels at detail work but may require supplementary tools for bigger projects.

- Belt Durability: The sanding belts or wheels on File Sanders may wear out relatively quickly, necessitating frequent replacements, which can add to the tool's overall cost.

Projects Best Suited for the File Sander:

- Woodworking: Craftsmen and woodworkers can use the File Sander to shape intricate designs smooth edges, and finish fine woodworking projects, such as carving details, decorative moldings, and inlays.

- Furniture Restoration: Restoring antique or vintage furniture often involves intricate detail work, which the File Sander can handle with precision, ensuring a polished final product.

- Model Making: Hobbyists engaged in model shipbuilding, dollhouse construction, or architectural modeling will find the File Sander indispensable for achieving precision and realism in their miniature creations.

- Automotive Restoration: DIY car enthusiasts can use the File Sander for detailed work on auto body repairs, ensuring a smooth finish around curved edges and tight corners.

- Metalworking: The File Sander can also be used for metal fabrication projects, such as shaping metal components, deburring edges, and preparing surfaces for welding or painting.

Who Should Benefit from Buying the File Sander:

The File Sander is a valuable tool for a range of users, including:

- Woodworkers: Professional and hobbyist woodworkers who require precision and fine detailing in their projects.

- DIY Enthusiasts: Individuals passionate about DIY projects, home improvement, and crafting who seek a versatile tool for small to medium-sized tasks.

- Artists and Sculptors: Artists and sculptors looking to refine their creations with intricate details and smooth surfaces.

- Restorers: Those engaged in furniture, automotive, or antique restoration work where precision sanding is crucial.

- Model Makers: Hobbyists and professionals involved in model making, whether for architectural models, miniatures, or scale models.

In short, the File Sander, or Finger Sander, is a specialized tool known for its precision and versatility in fine detailing and finishing work.

While it has its limitations, it is an indispensable addition to the toolkit of woodworkers, DIY enthusiasts, artists, and anyone seeking to achieve intricate, high-quality results in their projects.

Its ability to access tight spaces and provide controlled sanding makes it an invaluable asset for various applications.

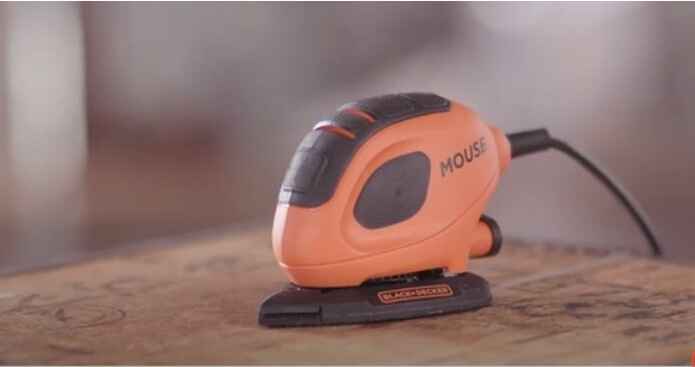

Mouse Sander: Precision and Power at Your Fingertips

The Mouse Sander, often hailed as a compact powerhouse in the world of sanding tools, has earned its stripes as a versatile and indispensable instrument for various DIY and professional projects. This innovative tool derives its name from its compact size and unique shape, which resembles a mouse.

How It Works:

The Mouse Sander is designed to streamline the sanding process, making it more efficient and precise. Its primary components include a small, triangular sanding pad and a powerful motor.

This triangular shape is ideal for reaching tight corners and confined spaces, allowing for unparalleled precision during sanding. The sandpaper attaches to the pad via a hook-and-loop system, making it quick and easy to replace when it wears out.

When the Mouse Sander is powered on, the motor generates a rapid oscillating motion in the sanding pad. This motion removes material efficiently and minimizes the risk of leaving swirl marks or uneven surfaces. The user guides the sander over the target area, and the Mouse Sander's design and oscillating action take care of the rest.

Pros:

- Precision and Versatility: The Mouse Sander's triangular design and oscillating motion make it perfect for sanding in tight spaces, intricate patterns, and corners that are challenging to reach with larger sanders. It excels at detail work.

- Efficiency: The powerful motor combined with the precise motion ensures that material is removed quickly and evenly, saving time and effort compared to hand sanding.

- Ease of Use: Its compact size and lightweight build make it incredibly easy to handle, reducing user fatigue and allowing for extended periods of operation.

- Dust Extraction: Many models of Mouse Sanders come equipped with a dust collection system. This feature keeps your workspace cleaner and healthier by capturing and containing the fine dust generated during sanding.

- Affordability: Mouse Sanders are generally budget-friendly, making them accessible to DIY enthusiasts and professionals without breaking the bank.

Cons:

- Limited Sanding Surface: The Mouse Sander may not be the best choice for large, flat surfaces due to its small size. Larger sanders like orbital or belt sanders are more efficient for such projects.

- Vibrations and Noise: The intense oscillating motion of the Mouse Sander can lead to increased vibrations and noise levels, which may be uncomfortable for some users over extended periods.

Best Suited Projects:

The Mouse Sander shines in a variety of projects, including:

- Furniture Restoration: It excels at refinishing wooden furniture, where precision and intricate detail work are crucial.

- Trim and Molding: Ideal for sanding baseboards, crown molding, and other intricate trim work.

- DIY Crafts: Perfect for smoothing edges and surfaces in woodworking and crafting projects.

- Home Renovations: Great for sanding walls in preparation for painting or smoothing out rough spots on drywall.

Who Should Get Benefits:

- DIY Enthusiasts: Hobbyists and DIY enthusiasts looking to tackle home improvement and crafting projects can greatly benefit from the Mouse Sander's ease of use and precision.

- Woodworkers: Professionals and hobbyist woodworkers find the Mouse Sander invaluable for its ability to refine intricate woodwork.

- Interior Decorators: Those involved in interior design and decoration will appreciate its ability to achieve flawless finishes on various surfaces.

- Homeowners: Individuals engaged in home maintenance and renovations can streamline their projects with this tool, especially when dealing with intricate spaces.

In short, the Mouse Sander is a remarkable tool designed to make sanding tasks easier and more efficient, particularly in situations requiring precision and access to tight spaces.

Its numerous advantages make it a valuable addition to the toolkit of DIY enthusiasts, woodworkers, and anyone needing meticulous surface preparation.

While it may have some limitations, its pros outweigh the cons, making it a versatile and indispensable tool for many projects.

Random Orbital Sander: A Versatile Woodworking Powerhouse

The orbital sander, specifically the random orbital sander, is a highly versatile and indispensable power tool for woodworking enthusiasts, DIYers, and professional artisans alike.

This tool has revolutionized the way wood surfaces are sanded, providing efficiency, precision, and ease of use that was previously unparalleled.

How It Works:

The random orbital sander operates on a simple yet ingenious principle. It combines orbital and rotary motion to produce a unique sanding action that leaves surfaces smooth and virtually swirl-free. Here's how it works:

- Circular Motion: The sanding pad on a random orbital sander moves in a circular motion. This motion ensures the abrasive paper doesn't linger in one spot for too long, preventing gouges or uneven sanding.

- Orbital Motion: Simultaneously, the sanding pad moves in an elliptical orbital pattern. This randomizes the scratch pattern on the wood, eliminating the swirl marks common with traditional orbital sanders.

- Variable Speed: Most random orbital sanders have adjustable speed settings, allowing the user to control the aggressiveness of the sanding action. This flexibility makes it suitable for a wide range of projects and materials.

Pros:

- Versatility: Random orbital sanders are incredibly versatile, making them suitable for various projects. Whether you're refinishing furniture, smoothing rough wood surfaces, or preparing a wooden floor for finishing, these sanders can handle it all.

- Efficiency: Their unique sanding action removes material quickly and efficiently, saving time and effort. The combination of circular and orbital motion ensures a smooth, consistent finish.

- Dust Collection: Many random orbital sanders have dust collection systems or can be easily connected to a vacuum. This feature keeps your workspace cleaner and improves air quality by reducing airborne dust particles.

- User-Friendly: They are designed with ergonomics in mind, making them comfortable for extended periods. Their random sanding pattern also reduces the risk of leaving unsightly swirl marks, even for beginners.

- Finish Quality: Random orbital sanders excel at producing a high-quality finish. Whether working on a woodworking project or preparing surfaces for painting, you can easily achieve a professional-level finish.

Cons:

- Cost: Random orbital sanders tend to be more expensive than other types of sanders, which might deter budget-conscious DIYers.

- Noise and Vibration: While designed for comfort, some models can still generate significant noise and vibration, potentially leading to user discomfort during extended use.

Ideal Projects:

Random orbital sanders are exceptionally well-suited for a wide range of projects, including but not limited to:

- Furniture Refinishing: These sanders can remove old finishes, paint, and imperfections while leaving a smooth surface for refinishing.

- Woodworking: From shaping wooden pieces to sanding intricate details, random orbital sanders are a must-have for woodworking enthusiasts.

- Cabinetry: Whether building new cabinets or refinishing existing ones, these sanders make the job easier and more precise.

- Flooring: When tackling hardwood floors, random orbital sanders remove imperfections and prepare the surface for staining or finishing.

Who Benefits:

- Woodworkers: Professionals and hobbyists in the woodworking industry benefit from the precision and efficiency of random orbital sanders, as they can achieve exceptional finishes on their projects.

- DIY Enthusiasts: Home improvement and DIY enthusiasts find random orbital sanders invaluable for many projects, making them a wise investment for those who frequently work with wood.

In short, the random orbital sander is a remarkable tool that combines precision, efficiency, and versatility. Its unique sanding action and numerous benefits make it an essential addition to any woodworker's or DIY enthusiast's toolkit.

While it may come with a higher price tag and some noise and vibration, its advantages far outweigh the drawbacks, making it a valuable asset for those who demand top-notch results in their woodworking projects.

Oscillating Spindle Sander: A Precision Woodworking Companion

When achieving smooth, contoured surfaces and precise curves in woodworking, the oscillating spindle sander is an indispensable tool in the craftsman's arsenal.

This versatile machine operates on a straightforward yet highly effective principle to help woodworkers, hobbyists, and DIY enthusiasts easily refine their projects.

How It Works:

An oscillating spindle sander operates by combining rotary and oscillating movements. Its core consists of a spindle (usually made of rubber) that protrudes from a sanding drum.

This spindle is driven by a motor, which rotates it at high speeds. What sets an oscillating spindle sander apart is its unique oscillation mechanism.

The spindle rotates and moves up and down reciprocally, creating spinning and oscillating movements. This oscillation, typically with a range of 1/4 to 1 inch, ensures that the sanding sleeve wraps uniformly around the workpiece, resulting in a smoother, more evenly sanded surface.

Pros:

- Precise Sanding: The oscillating motion of the spindle, coupled with its ability to handle various spindle sizes, allows for exceptionally precise sanding on intricate curves, contours, and irregular shapes. This level of precision is challenging to achieve with other sanding tools.

- Reduced Sanding Marks: The spindle oscillation minimizes the risk of creating visible sanding marks, ensuring a consistent finish across the entire workpiece. This is particularly crucial for high-quality woodworking projects.

- Efficient Dust Collection: Many oscillating spindle sanders have effective dust collection systems that clean your workspace and reduce airborne dust. This feature promotes a healthier working environment and extends the life of the sanding sleeves.

- Versatility: With various spindle sizes and grit options, these sanders suit various materials, including wood, plastic, and metal. This versatility makes them a valuable addition to any workshop.

- Enhanced Safety: The design of an oscillating spindle sander minimizes the risk of kickback and allows for safer sanding, even on small or irregularly shaped workpieces. Additionally, the oscillating motion reduces the chance of overheating and damaging the wood.

Cons:

- Limited Sanding Width: Oscillating spindle sanders are primarily designed for sanding smaller workpieces and might not be suitable for larger projects. This limitation means you might need to use other sanding tools for wide surfaces.

- Footprint and Cost: Quality oscillating spindle sanders can take up a significant amount of space in your workshop and are more expensive than other sanding tools. However, their precision and versatility often justify the investment for serious woodworkers.

Projects Suited for the Oscillating Spindle Sander:

Oscillating spindle sanders excel in tasks that require intricate shaping and contouring. These include:

- Cabinetmaking: Perfect for smoothing the edges and curves of cabinet doors and drawers.

- Chair and furniture Making: Ideal for shaping chair legs, armrests, and other intricate furniture components.

- Luthiery: Essential for crafting musical instruments like guitars, where precision is paramount.

- Scrollwork and Woodturning: Great for refining scrollwork and enhancing the appearance of turned wood items.

- Restoration Work: Excellent for restoring antique furniture and other wooden artifacts to their former glory.

Who Benefits from Owning an Oscillating Spindle Sander:

- Woodworkers: Professionals and hobbyists prioritizing precision and high-quality finishes in their woodworking projects will find an oscillating spindle sander indispensable.

- Cabinetmakers: Those engaged in cabinetmaking will appreciate the tool's ability to create perfectly smooth and polished cabinet components.

- Furniture Makers: Craftsmen and artisans who design and build furniture will rely on this sander for intricate shaping and finishing.

- Instrument Makers: Luthiers and instrument makers will find the oscillating spindle sander invaluable for crafting musical instruments with superior craftsmanship.

- Restorers: Individuals restoring antique furniture or other wooden items can delicately use this tool to rejuvenate surfaces and contours.

In short, the oscillating spindle sander is a precision woodworking machine that combines rotary and oscillating movements to deliver exceptional results in shaping and sanding.

While it has a few limitations, its pros, including precise sanding, reduced sanding marks, and efficient dust collection, make it a valuable asset for woodworking professionals and enthusiasts seeking top-notch results in their projects.

Whether you're a cabinetmaker, furniture maker, or hobbyist with a penchant for precision, adding an oscillating spindle sander to your workshop is a decision that can significantly elevate your woodworking game.

Palm Sander (Quarter Sheet Sander): A Versatile Woodworking Companion

The palm sander, often referred to as the quarter sheet sander, is a versatile power tool that has become a staple in the toolkit of both professional woodworkers and DIY enthusiasts. Its compact design and ease of use make it a popular choice for sanding projects.

How it Works:

The palm sander is a handheld power tool specifically designed for sanding tasks. It derives its name from its size and shape, resembling a quarter sheet of sandpaper. Here's how it works:

- Motor and Sanding Plate: The heart of the palm sander is its electric motor, which drives the sanding plate in a rapid orbital motion. This motion helps to sand the surface and prevent swirl marks or scratches evenly.

- Sanding Sheet: A quarter sheet of sandpaper is secured to the sanding plate using clamps or adhesive. The sandpaper grit can be chosen based on the abrasiveness required for the task.

- Dust Collection: Many palm sanders have a dust collection system that helps keep the work area clean. A dust bag or vacuum attachment can be connected to the sander to capture sanding debris, improving visibility and air quality.

- User Control: The operator holds the sander by its ergonomic handle, allowing for precise control and maneuverability.

Pros:

- Versatility: Palm sanders are incredibly versatile and suitable for various projects, including furniture refinishing, smoothing wooden surfaces, and preparing surfaces for painting or staining.

- Efficiency: Their orbital motion and high-speed sanding action result in a smooth, even finish, reducing the time and effort required to complete sanding tasks.

- Easy to Use: Palm sanders are user-friendly, making them an excellent choice for beginners. They require minimal effort to operate and provide consistent results.

- Dust Collection: Many models come with efficient dust collection systems, which keep the work area clean and promote a healthier working environment.

- Compact Design: Their small size and lightweight build make them highly portable and easy to handle, even in tight or hard-to-reach spaces.

Cons:

- Limited Stock Removal: While palm sanders are excellent for finishing work, they are not designed for heavy stock removal. For tasks requiring substantial material removal, a different type of sander, like a belt sander, may be more suitable.

- Vibration and Noise: Like most power tools, palm sanders can produce vibration and noise during operation. While this is manageable for short tasks, prolonged use can cause discomfort.

Projects Suited for Palm Sanders:

- Wood Finishing: Palm sanders are ideal for smoothing wooden surfaces, including cabinets, tables, and chairs, before applying finishes like paint or varnish.

- Refinishing Furniture: Whether restoring an antique piece or giving a new look to an old favorite, palm sanders can help remove old finishes and prepare the wood for refinishing.

- Sanding Between Coats: When working on projects requiring multiple coats of paint or finish, a palm sander can achieve a smooth surface between each coat.

- Trim and Molding: Palm sanders' small size and precision make them perfect for sanding trim and molding details in home improvement projects.

Who Benefits from Owning a Palm Sander:

- Woodworkers: Both professional woodworkers and hobbyists can benefit from having a palm sander in their toolkit. It streamlines finishing processes and ensures a professional, polished result.

- DIY Enthusiasts: Home improvement enthusiasts looking to tackle furniture restoration, cabinet refinishing, or other woodworking projects will find a palm sander indispensable due to its ease of use and versatility.

- Craftsmen: Artists and artisans who work with wood as a medium for their creations can achieve fine detailing and precision with a palm sander.

In short, the palm sander, or quarter sheet sander, is a valuable addition to any woodworking toolkit. Its versatility, efficiency, and ease of use make it an excellent choice for various sanding tasks, while its compact design ensures accessibility even in tight spaces.

While it may not be suitable for heavy stock removal, its benefits far outweigh its limitations, making it a must-have tool for professionals and DIY enthusiasts.

Sanding Blocks: The Handy Tool for Smoother Surfaces

Sanding blocks are essential tools in the arsenal of both professional craftsmen and DIY enthusiasts, playing a pivotal role in achieving smooth and polished surfaces.

These versatile tools come in various shapes and sizes, but they all serve a common purpose: to remove imperfections, rough spots, or old finishes from a wide range of materials, leaving behind a refined and even surface.

How Sanding Blocks Work:

Sanding blocks are manual tools designed for precision and control. They consist of a block-like structure made from foam, rubber, or wood, with an abrasive surface attached to one side. This abrasive surface can be in the form of sandpaper or an abrasive sponge.

To use a sanding block effectively, you simply apply even pressure while moving it back and forth over the surface you want to smooth. The block's design ensures the pressure is evenly distributed, preventing uneven wear and providing a consistent finish.

The abrasive material on the sanding block gradually wears down as it comes into contact with the surface, effectively removing layers of material and smoothing out imperfections. The user can choose the grit size of the sandpaper or sponge to match the abrasiveness required for the specific project.

Pros:

- Precision and Control: Sanding blocks offer unparalleled precision, allowing users to target specific areas or angles easily. This level of control is especially valuable when working on intricate projects or delicate surfaces.

- Uniform Results: Sanding blocks distribute pressure evenly, resulting in a consistent finish across the entire surface. This eliminates the risk of over-sanding or creating uneven spots.

- Versatility: Sanding blocks can be used on various materials, including wood, metal, plastic, and drywall. This versatility makes them a valuable tool for various projects.

- Ergonomic Design: Most sanding blocks are designed with user comfort in mind, featuring ergonomic handles and lightweight construction, reducing fatigue during extended use.

- Cost-Efficiency: Sanding blocks are affordable and require no power source, reducing ongoing operational costs. They are a budget-friendly option for both professionals and hobbyists.

Cons:

- Slower Than Powered Sanders: Sanding blocks offer precision and control but are generally slower than powered sanders. For large-scale projects, using a power sander may be more time-efficient.

- Requires Physical Effort: Using a sanding block involves manual labor, which can be tiring, especially during extended periods of use. Some individuals with physical limitations may find this challenging.

Projects Suited for Sanding Blocks:

Sanding blocks excel in a variety of projects, including:

- Furniture Refinishing: Sanding blocks are ideal for preparing surfaces before painting or staining furniture, ensuring a smooth and even finish.

- Woodworking: Sanding blocks are indispensable for woodworking projects, whether you're shaping intricate details or smoothing rough edges on wooden pieces.

- Drywall Repair: When patching or repairing drywall, sanding blocks help feather out joint compound or spackle, creating a seamless finish.

- Automotive Restoration: Sanding blocks can be used to remove old paint, rust, and imperfections from car surfaces, preparing them for a new coat of paint.

- Metalworking: Precise metal finishing, such as deburring or smoothing welds, can be achieved with sanding blocks.

Who Benefits from Using Sanding Blocks:

- Woodworkers: Craftsmen working with wood will appreciate the precision and control that sanding blocks offer in achieving a polished finish on their projects.

- DIY Enthusiasts: Hobbyists and DIY enthusiasts can benefit from the cost-efficiency and ease of use of sanding blocks for various home improvement projects.

- Restorers and Refinishers: Professionals involved in furniture restoration, automotive refinishing, or other restoration work will find sanding blocks indispensable for achieving top-notch results.

- Artisans: Artists and artisans who require precision in their work can use sanding blocks to shape and refine their creations.

In short, sanding blocks are invaluable tools for achieving smooth and refined surfaces across various materials and projects. Their precision, versatility, and cost-effectiveness make them a must-have for professionals and DIY enthusiasts seeking to elevate the quality of their work.

While they may not be the fastest option for large-scale projects and require physical effort, the benefits of sanding blocks far outweigh their limitations, making them an essential addition to any toolkit.

Sheet Sander (Finishing Sander): A Versatile Woodworking Tool

A sheet sander, often referred to as a finishing sander, is a powerful and versatile tool used in woodworking and DIY projects. It plays a crucial role in achieving a smooth and polished surface on various materials, primarily wood.

How It Works:

A sheet sander is designed for fine-finishing tasks, making it an essential tool in woodworking and furniture making. Its operation is relatively straightforward:

- Sandpaper Attachment: Sheet sanders typically use rectangular sheets of sandpaper, which are attached to the sander's base using clamps or adhesive. These sandpapers come in various grit sizes, allowing you to choose the level of coarseness for your specific project.

- Vibrating Base: The sheet sander features a vibrating base that moves the sandpaper back and forth in a linear motion. This controlled oscillation minimizes the risk of swirl marks and ensures a uniform finish.

- User Control: The user holds the sander by its handle, applying gentle downward pressure to the sanded surface. The vibrating base does the work, removing material and smoothing the surface.

- Dust Collection: Many modern sheet sanders come equipped with dust collection systems, either through a built-in dust bag or the ability to attach an external vacuum. This feature helps maintain a clean working environment and prevents fine dust particles from becoming airborne.

Pros:

- Smooth Finish: Sheet sanders are smooth and even finish, making them ideal for fine woodworking projects like cabinets, furniture, and trim work.

- Easy to Control: Their linear motion and lightweight design make sheet sanders easy to maneuver and control, reducing the risk of over-sanding or damaging the material.

- Versatility: Sheet sanders can be used on a wide range of materials, not just wood. They are also effective on metal, plastic, and drywall surfaces.

- Quick Sandpaper Changes: Changing sandpaper sheets is a breeze with sheet sanders, allowing you to quickly switch between grits or replace worn-out paper.

- Dust Management: Many models have effective dust collection systems, improving air quality and reducing cleanup time.

Cons:

- Limited Stock Removal: Sheet sanders are not designed for heavy material removal. If you have rough, uneven surfaces that require significant stock removal, you may need a different type of sander, such as a belt sander or a random orbital sander.

- Limited Reach: Due to their rectangular shape, sheet sanders may struggle to reach tight corners or confined spaces, requiring additional hand sanding or using other specialized sanders.

Best Suited Projects:

Sheet sanders are particularly well-suited for projects that demand a fine, smooth finish. These include:

- Furniture Making: Whether crafting a dining table, a chair, or a dresser, sheet sanders can help you achieve the perfect surface for staining or painting.

- Cabinetry: Sheet sanders excel at sanding cabinet doors, drawers, and frames, ensuring a flawless finish that enhances the overall look of your kitchen or bathroom.

- Trim Work: Baseboards, crown molding, and other trim elements benefit from the precision and control of sheet sanders.

- Wooden Flooring: When refinishing hardwood floors, sheet sanders are used for the final finishing passes to create a silky-smooth surface.

- DIY Home Improvement: Sheet sanders are a valuable tool for DIY enthusiasts tackling various home improvement tasks, from sanding drywall seams to refinishing old furniture.

Who Benefits from Owning a Sheet Sander:

- Woodworkers: Professional woodworkers and hobbyists will find sheet sanders indispensable for creating fine, polished surfaces on their projects.

- DIY Enthusiasts: Homeowners who enjoy tackling DIY projects around the house will appreciate sheet sanders' versatility and precision for various tasks.

In short, the sheet sander, or finishing sander, is a valuable tool in woodworking and DIY. Its ability to provide a smooth, even finish on various materials makes it an essential addition to any workshop or toolbox.

While it may have limitations regarding stock removal and reaching tight spaces, its numerous benefits far outweigh these drawbacks, making it an excellent investment for those who value quality craftsmanship and impeccable finishes in their projects.

Straight Line Sander: A Versatile Sanding Solution

The straight-line sander is a powerful and versatile tool used in various industries and DIY projects for sanding, smoothing, and finishing surfaces. It is a valuable addition to any workshop or toolkit due to its unique design and functionality.

How It Works:

The straight-line sander, a linear or inline sander, operates on a simple yet effective principle. It consists of a rectangular sanding pad or shoe that moves linearly back and forth, much like a reciprocating saw.

This motion is typically powered by an air compressor, making it a pneumatic tool, although some electric models are available.

- Efficient Material Removal: The linear motion of the sanding pad ensures a consistent and efficient removal of material, making it suitable for tasks that require quick stock removal or leveling surfaces.

- Uniform Finish: The straight line sander provides a smooth and uniform finish, reducing the need for additional sanding or surface preparation.

- Reduced Swirl Marks: Unlike rotary sanders, straight line sanders create fewer swirl marks on the surface, resulting in a cleaner and more professional-looking finish.

- Versatile Grit Options: Various grit sandpaper can be attached to the sanding shoe, allowing users to choose the level of abrasiveness needed for the specific task.