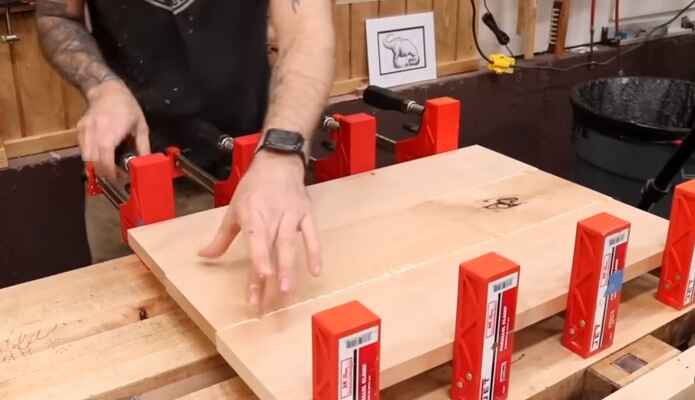

Parallel clamps are versatile tools used in woodworking and carpentry. They excel at securely holding large panels and boards parallel during glue-ups, ensuring precise alignment for strong and seamless joints in furniture and other projects.

If you're just starting out, you've probably heard about parallel clamps but might be wondering, "What are parallel clamps used for?" Well, you're in the right place. In this beginner-friendly guide, we'll unravel the mystery behind parallel clamps, exploring their versatile applications in woodworking. From securing joints to providing stability during glue-ups, parallel clamps are indispensable tools that every aspiring woodworker should have in their arsenal. Let's dive into the basics and discover how these clamps can elevate your woodworking projects.

Parallel clamps are an essential tool for woodworking and various other applications. They are particularly valuable for improving workbench productivity due to their design and functionality. Here are some ways in which parallel clamps can help enhance your workbench productivity:

1. Secure and Stable Clamping:

Parallel clamps provide a secure and stable grip on your workpiece. Their parallel jaws remain parallel throughout the clamping process, ensuring even pressure across the entire surface. This stability reduces the chances of your workpiece shifting or becoming misaligned during a project.

2. Reduced Setup Time:

Parallel clamps are quick and easy to set up, which saves you valuable time. You can adjust the clamping width by simply turning the handle, making it effortless to accommodate various workpiece sizes without the need for constant adjustments or multiple clamps.

3. Improved Precision:

The parallel clamps' ability to apply consistent pressure helps achieve precise and accurate glue-ups, joinery, and assembly work. This precision reduces the need for rework, leading to better-finished products.

4. Minimized Material Waste:

Parallel clamps can evenly distribute pressure across wide workpieces, reducing the likelihood of material deformation or warping. This can help minimize material waste and save money on expensive wood or other materials.

5. Increased Versatility:

Parallel clamps can be used for a wide range of tasks, including edge-gluing boards, assembling large projects, clamping jigs and fixtures, and more. Their versatility means you can use them for various projects on your workbench.

6. Enhanced Safety:

Proper clamping with parallel clamps ensures that your workpiece remains securely in place, reducing the risk of accidents and injuries. It's crucial to work safely, and parallel clamps contribute to a safer work environment.

7. Improved Workflow:

With parallel clamps, you can efficiently glue-up multiple pieces simultaneously, saving time during larger projects. This streamlines your workflow and allows you to complete projects faster.

8. Consistency in Results:

The even pressure applied by parallel clamps helps maintain consistency in your woodworking or assembly tasks. This is especially important when creating multiple identical pieces for furniture or cabinetry.

9. Less Stress on Your Hands:

The ergonomic handles and the smooth operation of parallel clamps make them easy to use and require less effort to apply pressure compared to some other types of clamps. This reduces hand fatigue during long work sessions.

10. Longevity and Durability:

High-quality parallel clamps are built to last, making them a long-term investment. Their durable construction ensures that they remain reliable and functional over time.

In summary, parallel clamps are an indispensable tool for any woodworker or DIY enthusiast. They improve workbench productivity by providing secure and stable clamping, reducing setup time, enhancing precision, minimizing material waste, increasing versatility, and contributing to a safer and more efficient work environment. Investing in high-quality parallel clamps can significantly improve the quality of your woodworking projects and make your workbench more productive.

How many parallel clamps do I need for my woodworking project?

It depends on the project. For a small project, you might only need two clamps. For a larger project, you might need four or six clamps.

Clamps are an essential part of any woodworking project. They hold the boards in place while you're working on them, which prevents them from slipping and causing further damage. Clamps also help to keep the boards adequately aligned, which is essential for ensuring a smooth, finished product.

If you're starting out in woodworking, investing in a few different types of clamps might be a good idea. This will allow you to tackle a variety of projects with ease. The most popular clamps are parallel clamps, F-style clamps, and C-clamps.

What are parallel clamps used for in woodworking?

Woodworking is a hobby that many people enjoy. It can be a great way to relax and make something beautiful or functional at the same time. One of the essential tools in woodworking is the clamp. Clamps hold pieces of wood together while they are being worked on. There are many clamps, but one of the most popular is the parallel clamp.

Parallel clamps are very versatile and can be used for various tasks. Here are ten of the most popular uses for parallel clamps in woodworking:

1. Gluing:

Parallel clamps are often used when gluing pieces of wood together. They can help to hold the pieces in place while the glue dries.

2. Drilling:

A clamp can hold the wood in place when drilling holes in the wood. This prevents the wood from moving and ensures that the holes are drilled in the correct location.

3. Sawing:

A clamp can hold a piece of wood in place while being cut with a saw. This helps to ensure that the cut is straight and that the piece of wood does not move.

4. Routing:

When using a router, a clamp can hold the wood in place. This prevents the router from moving and ensures that the routing is done in the correct location.

5. Planing:

When planing a piece of wood, a clamp can hold it in place. This helps ensure that the surface is planned evenly and that the wood does not move.

6. Sanding:

When sanding a piece of wood, a clamp can be used to hold it in place. This helps to ensure that the surface is being sanded evenly and that the wood does not move.

7. Painting:

When painting a piece of wood, a clamp can hold it in place. This helps to ensure that the paint is applied evenly and that the wood does not move.

8. Staining:

When staining a piece of wood, a clamp can be used to hold it in place. This helps to ensure that the stain is applied evenly and that the wood does not move.

9. Varnishing:

When varnishing a piece of wood, a clamp can hold it in place. This helps to ensure that the varnish is applied evenly and that the wood does not move.

10. Assembling:

When assembling a piece of furniture, a clamp can hold the pieces together while they are being joined. This helps to ensure that the furniture is assembled correctly and that the pieces do not move.

Parallel clamps are versatile tools that can be used for many different tasks in woodworking. They can help ensure that your projects look great by holding the pieces in place while you work. So, next time you are working on a woodworking project, be sure to use a clamp!

What are some of the benefits of using parallel clamps in woodworking?

When it comes to woodworking, the clamp is one of the essential tools in your arsenal. Clamps come in all shapes and sizes, but one of the most versatile and handy types is the parallel clamp. Here are five benefits of using parallel clamps in your woodworking projects.

1. Greater holding power:

Compared to other clamps, parallel clamps have much greater holding power. This is due to their unique design, which features two jaws that grip the workpiece from both sides. This gives them a much stronger grip than other clamps, which is ideal for projects that require a lot of holding power, such as gluing or sanding.

2. More versatile:

Parallel clamps are more versatile than other clamps. This is because they can be used in various ways, such as clamping two pieces of wood together or clamping a workpiece to a table. This makes them perfect for any woodworking project.

3. Easy to use:

Another benefit of parallel clamps is that they are very easy to use. This is due to their simple design, which makes them quick and easy to set up and use. They are also effortless to adjust, so you can quickly change the pressure you are applying to the workpiece.

4. Safe:

Parallel clamps are much safer than other clamps. This is because they do not have any moving parts, so there is no risk of them becoming dislodged and causing injury. Additionally, they are made from high-quality materials designed to withstand a lot of wear and tear, so you can be sure they will last for many years.

5. Affordable:

Finally, parallel clamps are very affordable. This is because they are mass-produced, which means they are available at a fraction of the cost of other types of clamps. This makes them an excellent value for money and a great investment for any woodworker.

If you are looking for a versatile, easy-to-use, and affordable clamp, then parallel clamps are the perfect choice for you. They are sure to make your woodworking projects easier and more enjoyable with their many benefits. So why not give them a try today?

Tips on how to get the most out of parallel clamps in woodworking?

Parallel clamps are an essential tool for anyone who works with wood. They're great for clamping boards together while you're gluing them, and they can also be used to hold them in place while cutting them.

Here are five tips on how to get the most out of your parallel clamps:

1. Get to know your clamps

There are many different types of parallel clamps available on the market, so it's essential to know which is right for your project. Do some research to find out the features and benefits of each clamp type, and then decide which one will work best for you.

2. Consider the size of your project

When choosing parallel clamps, it's important to consider the size of your project. If you're working on a large project, you'll need clamps that can reach across the entire piece of wood. For smaller projects, you can get away with using smaller clamps.

3. Invest in quality clamps

While it may be tempting to save money by buying cheaper clamps, this is usually not a good idea. Cheap clamps are often made of inferior materials and can break easily. This can cause severe damage to your project, so it's worth investing in high-quality clamps.

4. Use the right clamping pressure

Applying too much pressure to your project can damage it, so it's important to use the right amount of clamping pressure. When in doubt, err on the side of using less pressure. You can always add more pressure if needed.

5. Be careful when removing clamps

When you're finished with your project, be careful when removing the clamps. You could damage the wood or break the clamps if you're not careful. Take your time and be gentle to avoid any problems.

Follow these tips, and you'll be sure to get the most out of your parallel clamps. With a little care, they can help you create beautiful woodworking projects that will last for years.

Final Words

Though there are many uses for the parallel clamp, perhaps its most important contribution is in the realm of woodworking. By understanding how to use this tool correctly, you can complete various tasks that would otherwise be difficult or impossible. With a bit of practice, you'll be able to create beautiful and intricate pieces that will impress anyone who sees them. So what are you waiting for? Get out there and start using your parallel clamps to their full potential!