Woodworking clamps come in various types, including bar clamps for long pieces, parallel jaw clamps for precise alignment, and spring clamps for quick tasks. Each serves a unique purpose, enhancing precision and efficiency in woodworking projects.

Embarking on a woodworking journey can be both exciting and challenging for beginners. One essential aspect of this craft is understanding the various types of woodworking clamps and their specific applications. These seemingly simple tools play a crucial role in ensuring precision and stability in your projects. In this blog post, we'll unravel the mystery behind different woodworking clamps, providing beginners with a comprehensive guide to choosing the right clamp for various tasks. Let's dive into the world of woodworking clamps and discover how they can elevate your craftsmanship.

Woodworking clamps are essential for securing and holding wood pieces together during various woodworking tasks. They come in various types, including bar clamps, pipe clamps, and C-clamps. Clamps consist of a fixed and movable jaw, which can be adjusted to fit the workpiece. When choosing a clamp, consider size, capacity, and durability. Properly clamped wood ensures accurate cuts, tight joints, and stable assembly, making clamps indispensable for any woodworker. Learning how to use different types of clamps effectively is fundamental to achieving precision and quality in woodworking projects.

The primary function of clamps in woodworking

Clamps are essential tools in woodworking, and their primary function is to hold pieces of wood securely in place during various woodworking tasks. They are used to immobilize workpieces, ensuring precision, safety, and efficiency in woodworking projects. Here are some of the primary functions of clamps in woodworking:

1. Securing Workpieces:

Clamps hold wood pieces together or to a workbench, making it easier for woodworkers to perform tasks such as cutting, drilling, sanding, or gluing. This prevents the pieces from moving or shifting during the process.

2. Gluing and Clamping:

Clamps are crucial for maintaining even pressure and ensuring a strong bond between the pieces when applying adhesive or glue to joints. Proper clamping prevents gaps and ensures that the pieces are aligned correctly.

3. Joinery:

In joinery work, clamps hold pieces together while creating joints like dovetails, mortise and tenon, and finger joints. The clamps keep the pieces aligned during the assembly process.

4. Edge Banding:

Clamps hold edge banding materials (thin strips of wood or veneer) in place while glued to the edges of a panel or board. This ensures a clean and seamless edge finish.

5. Assembling Furniture:

When constructing furniture pieces, clamps help hold various components together while screws, dowels, or other fasteners are applied. This ensures that the pieces fit together precisely.

6. Veneering:

Clamps press veneer sheets onto a wooden surface, ensuring a tight bond between the veneer and the substrate. Veneering clamps, such as vacuum clamps or cauls, are designed specifically for this purpose.

7. Bent Lamination:

Woodworkers use clamps to shape and hold thin strips of wood in curved or bent forms during laminating processes, such as creating curved chair backs or musical instrument parts.

8. Carving and Shaping:

Clamps can secure workpieces while carving or shaping them with hand or power tools, ensuring safety and precision.

9. Preventing Warping:

Clamps can apply pressure to boards prone to warping, helping to straighten or flatten them over time.

10. Drying and Curing:

After applying finishes or adhesives, clamps can hold pieces correctly while they dry or cure. This ensures that the final result is level and free from distortions.

In summary, clamps are versatile tools that play a crucial role in woodworking by holding workpieces securely in place during various woodworking processes. They help ensure accuracy, alignment, and safety, ultimately contributing to the quality of the finished woodworking project. Different types of clamps, such as bar clamps, pipe clamps, C-clamps, and specialty clamps, are available to suit different woodworking tasks and requirements.

Common Types of Woodworking Clamps and Their Uses

Woodworking clamps are essential for securing workpieces, holding them, and applying pressure during various woodworking tasks. There are several types of woodworking clamps, each designed for specific purposes. Here's an in-depth list of common woodworking clamp types and their uses:

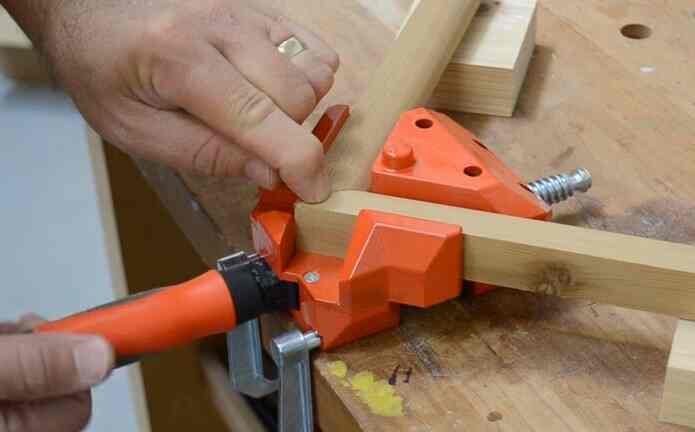

1. Angle Clamps

Angle clamps are versatile tools commonly used in woodworking, metalworking, and various DIY projects. They are designed to hold two pieces of material at a fixed angle, typically 90 degrees, ensuring precise and secure alignment during assembly or welding tasks.

Angle clamps feature a compact and sturdy design, often with adjustable jaws that accommodate different material thicknesses. Many angle clamps incorporate quick-release mechanisms, allowing for swift adjustments and easy removal of the clamped material.

These clamps are typically made from durable materials such as steel or aluminum, ensuring their longevity and reliability in various applications.

Ideal for a wide range of applications, angle clamps offer several benefits. They are indispensable when constructing right angles or securing materials at specific angles, ensuring the accuracy of projects like picture frames, cabinets, and furniture.

Angle clamps help maintain consistent and perpendicular joints, reducing the need for time-consuming measurements and minimizing the risk of errors. They are also invaluable in welding tasks, providing a secure hold for precise welding at 90-degree angles.

2. Band clamps or Strap Clamps

Band clamps, also known as strap clamps, are versatile tools used in various applications for securing and clamping objects together.

These clamps typically consist of a flexible band or strap made from materials such as steel, nylon, or leather, equipped with a mechanism for tightening the strap around the objects being joined.

The design of band clamps allows for easy adjustment to accommodate different shapes and sizes of workpieces, making them ideal for irregularly shaped objects or objects with complex contours.

Their characteristics include a ratcheting or tensioning mechanism that enables users to apply precise and uniform pressure, ensuring a secure and even hold. Some band clamps feature quick-release mechanisms for convenient removal after clamping.

Band clamps find ideal uses in woodworking, metalworking, and various other industries where temporary or permanent clamping is required. They excel in applications such as edge banding, gluing, laminating, and securing irregularly shaped workpieces.

Their benefits include distributing pressure evenly along the entire strap length, reducing the risk of marring or damaging delicate surfaces. Band clamps are also invaluable for holding materials in position during curing or drying, promoting precise alignment and a strong bond.

Moreover, their versatility allows for use in small-scale DIY projects and large-scale industrial applications, making them an indispensable tool for craftsmen and professionals.

3. Bench Clamp

Bench clamps are essential tools in woodworking and metalworking that provide stability and secure workpieces during various tasks. Typically consisting of a robust clamp mechanism attached to a sturdy base, bench clamps are designed to be mounted onto workbenches or tables. They come in various sizes and styles, including C-clamps, bar clamps, and quick-release clamps, each tailored to specific applications.

Bench clamps feature characteristics such as adjustable jaws, ensuring versatility in accommodating different workpiece sizes, and often include rubber or padded surfaces to prevent damage to materials. Their durable construction, usually composed of high-quality materials like steel or cast iron, ensures longevity and resilience in the workshop.

Ideal for a wide range of tasks, bench clamps offer numerous benefits. They firmly hold materials in place, allowing for precise cutting, drilling, sanding, and assembly. This stability promotes safer working conditions by minimizing the risk of slipping or movement, reducing the chances of accidents.

Bench clamps also enable single-handed operation, freeing up the user's other hand for more intricate tasks or adjustments. They enhance efficiency by streamlining workflow and ensuring consistent results, making them indispensable for professional artisans and hobbyists.

Bench clamps are portable and can be repositioned easily, making them versatile tools for various projects. Bench clamps are indispensable workshop accessories that improve precision, safety, and productivity in various woodworking and metalworking applications.

4. Bar Clamp

F-Clamps:

F-clamps, or bar clamps, or sliding clamps are versatile tools commonly used in woodworking, metalworking, and various other applications for securing workpieces firmly in place during cutting, gluing, or assembly processes. They are characterized by their distinctive "F" shape, which consists of a fixed jaw and a movable jaw connected by a long steel bar. The fixed jaw typically remains stationary, while the movable jaw can be adjusted along the bar to accommodate different workpiece sizes.

F-Clamps are designed to exert strong, even pressure on the workpiece, ensuring a secure hold and precise alignment. They often feature ergonomic handles for comfortable operation and are available in various sizes to suit different projects, with larger clamps capable of exerting greater force.

Ideal for a wide range of applications, F-Clamps offer several benefits. Their consistent, high-pressure clamping makes them indispensable for edge-gluing boards, joining materials, or holding pieces together during drilling and machining. The long reach of the bar allows for deep clamping, making them suitable for securing large or irregularly shaped workpieces.

F-Clamps are also prized for their ease of use and quick adjustment, enabling efficient work in professional and DIY settings. Additionally, their robust construction and durability ensure they can withstand heavy-duty work rigors, making them essential tools for any workshop or fabrication environment.

Sash Clamps:

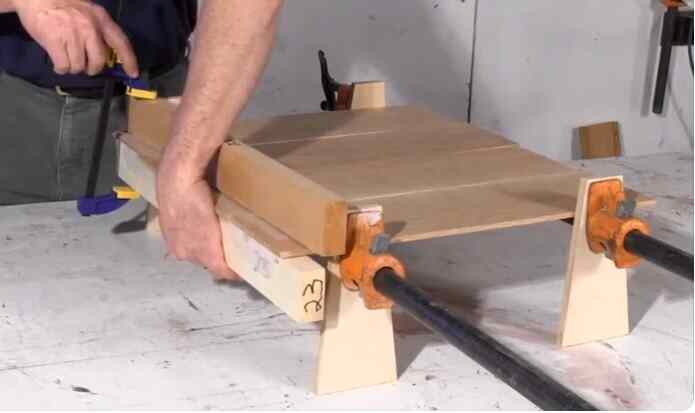

Sash Clamps are essential for woodworking and carpentry. They consist of two parallel bars made of sturdy materials like steel or aluminum, with one bar featuring a sliding head that can be adjusted along the length of the other. This design allows for a wide range of clamping capacities, making them versatile for various projects.

Sash clamps typically have wooden or plastic pads on their clamp faces to prevent damage to the workpiece. Their characteristics include high clamping pressure, stability, and ease of adjustment, ensuring a secure and precise hold on materials during gluing, assembly, or other woodworking tasks.

Ideal for a multitude of woodworking applications, sash clamps are indispensable in tasks requiring strong and stable clamping. They excel in joining and gluing large panels, laminating tabletops, assembling cabinets, doors, and frames, and holding workpieces securely while drying or curing.

The benefits of sash clamps lie in their ability to provide uniform pressure along the entire length of the workpiece, resulting in tight, even glue joints and preventing warping or misalignment. Their adjustability accommodates different-sized projects, and their durability ensures they can withstand the rigors of a busy workshop.

Sash clamps are indispensable for achieving professional-quality woodworking and ensuring the structural integrity of finished pieces.

Parallel Clamps:

Parallel clamps are essential tools in woodworking and metalworking, designed to securely hold workpieces in a parallel position during various assembly and gluing tasks. These clamps feature a robust and durable construction, typically consisting of a steel or aluminum frame with jaws that can be adjusted independently to accommodate materials of varying thicknesses.

The distinctive feature of parallel clamps is their ability to maintain consistent pressure across the entire length of the workpiece, ensuring even and uniform clamping. They often come with ergonomic handles for comfortable use and are available in various sizes to suit different project requirements.

The design of parallel clamps allows for precise alignment and prevents workpieces from shifting or buckling during glue-ups, resulting in high-quality, professional-looking finished products.

Ideal uses for parallel clamps include woodworking projects such as cabinet assembly, edge-gluing panels, and laminating tabletops. In metalworking, they are invaluable for welding applications where precise alignment is crucial.

The benefits of parallel clamps are manifold: they provide excellent clamping force distribution, reducing the risk of workpiece deformation. Their parallel jaw design minimizes the chances of misalignment, ensuring accurate and flush joints. This, in turn, saves time on sanding or additional adjustments after assembly.

Parallel clamps enhance productivity and produce high-quality, structurally sound items, making them indispensable tools for professional artisans and DIY enthusiasts.

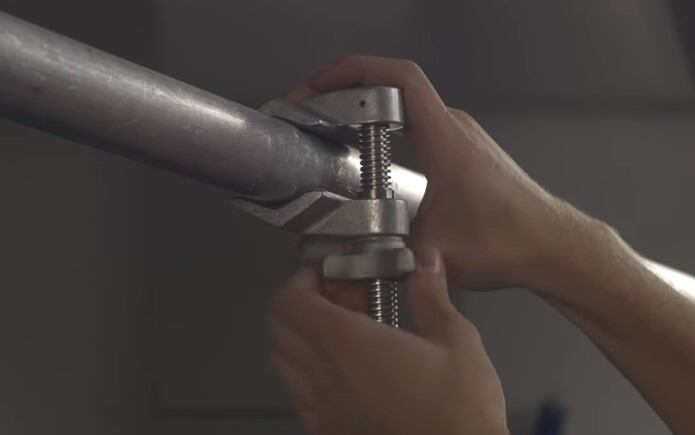

5. Bench Vise

A bench vise is a versatile and indispensable tool commonly found in workshops and garages. Its design typically consists of two parallel jaws, one fixed and the other movable, operated by a screw mechanism. These jaws securely hold various materials in place, such as wood, metal, or plastic, allowing for precise and stable work during tasks like sawing, drilling, filing, or welding.

Bench vises come in various sizes and styles, with some featuring additional features like swivel bases or pipe jaws, enhancing their adaptability for different applications. Their robust construction and durable materials make them capable of withstanding significant clamping force and resisting wear and tear, ensuring longevity and reliability in demanding work environments.

The ideal uses and benefits of a bench vise are numerous. Firstly, they provide exceptional stability and grip, enhancing safety and precision when working on intricate or heavy-duty projects. Artisans and DIY enthusiasts rely on bench vises for woodworking, metalworking, jewelry making, and even vehicle repairs.

Bench vises enable hands-free operation, freeing up the user's hands to focus on the task. This not only boosts productivity but also reduces the risk of accidents. Furthermore, the ability to hold materials at various angles and orientations, thanks to features like swivel bases, make bench vises incredibly versatile.

Overall, their capacity to securely hold and manipulate materials makes bench vises indispensable for various applications, making them a must-have tool for any workshop or garage.

6. Cardellini Clamp

The Cardellini Clamp is a versatile and robust grip equipment commonly used in film and photography. Its design consists of two sturdy jaws with adjustable tension, connected by a central hinge that can be tightened to grip various objects securely.

The clamp is typically made of durable materials like aluminum or steel and features rubber padding on the jaws to prevent damage to surfaces it clamps onto. Its distinctive design allows it to be attached to a wide range of surfaces, including pipes, poles, camera rigs, and lighting equipment, making it an indispensable tool for professionals in the field.

Ideal for a multitude of uses, the Cardellini Clamp offers several benefits. It is widely used for mounting cameras, lights, microphones, and other accessories on film sets and photography shoots in unconventional or hard-to-reach locations.

The clamp's strong grip ensures the equipment remains securely in place, reducing the risk of accidents and costly damages. Its versatility allows for quick adjustments and gear positioning, saving valuable time during shoots.

The Cardellini Clamp is favored for its reliability and adaptability, making it an indispensable tool for professionals seeking stability and flexibility in their work.

7. Carriage Clamp/C-clamp

A Carriage Clamp, often referred to as a C-clamp, is a versatile and essential tool in various industries and applications. It typically consists of two flat, rectangular jaws, one fixed and one adjustable, connected by a sturdy threaded screw.

The design of a Carriage Clamp allows it to securely hold objects together by applying pressure between the jaws when the screw is tightened. These clamps are commonly made from durable materials such as steel or cast iron to withstand substantial pressure and provide longevity.

Carriage Clamps find ideal use in woodworking, metalworking, welding, and construction tasks. They are invaluable for holding workpieces in place ensuring precision in cutting, drilling, gluing, or welding processes. Their adjustable nature allows for different workpiece sizes to be accommodated, making them a versatile choice for a wide range of projects.

The benefits of Carriage Clamps include their ability to provide strong and reliable clamping force, enhancing workpiece stability and accuracy. Additionally, they are relatively easy to use, making them a popular choice for professionals and hobbyists.

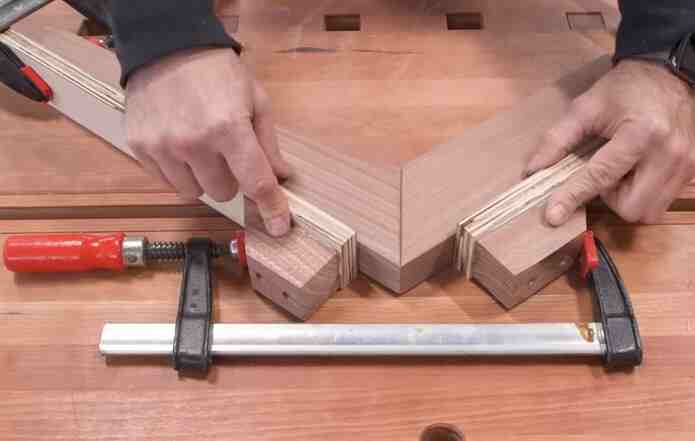

8. Corner Clamps

Corner clamps are essential tools in woodworking and carpentry, designed to securely hold two pieces of material at a right angle, forming a perfect 90-degree corner joint. These clamps typically feature a sturdy construction with adjustable jaws that can be tightened to grip the workpieces firmly.

They come in various designs, including L-shaped and T-shaped configurations, each suited to specific applications. The L-shaped corner clamp features one fixed jaw and one sliding jaw, while the T-shaped clamp has two sliding jaws, allowing for flexibility in holding materials of varying sizes.

The characteristics of corner clamps often include durable materials like metal or high-strength plastic, easy-to-use tightening mechanisms, and rubberized or padded surfaces to prevent damage to the workpieces.

Corner clamps find ideal uses in various woodworking and carpentry projects. They are particularly valuable when assembling cabinets, frames, shelves, and other furniture items that require precise right-angle joints. These clamps ensure that the workpieces remain perfectly aligned during glue-ups, screwing, or nailing, resulting in sturdy and professionally finished products.

The benefits of corner clamps include improved accuracy and consistency in corner joints, reduced effort and time spent on holding pieces in position, and decreased likelihood of errors that can compromise the overall quality of the project.

Corner clamps enhance safety by reducing the risk of accidental slips or misalignments, making them indispensable tools for both amateur and professional woodworkers.

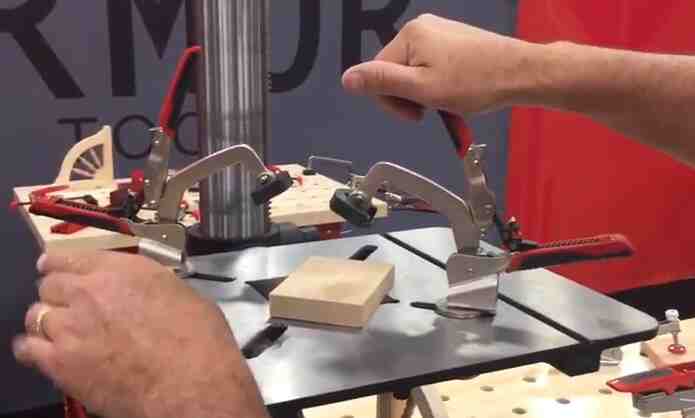

9. Drill Press Clamp

The Drill Press Clamp is an essential accessory designed to enhance the precision and safety of drilling operations on a drill press or similar machinery. Typically crafted from durable materials such as cast iron or steel, this clamp features a robust design with adjustable components.

It consists of a clamping mechanism that securely holds the workpiece in place, preventing any unwanted movement during drilling.

The clamp has threaded screws or levers that allow users to adjust the clamping pressure, accommodating various workpiece sizes and shapes.

The clamp often includes a swivel or pivoting base, enabling precise positioning of the workpiece for accurate hole placement. Its stability and firm grip make it an indispensable tool for woodworking, metalworking, and other applications requiring precise and controlled drilling.

The Drill Press Clamp finds ideal use in a wide range of tasks, including woodworking, metal fabrication, and DIY projects. Its primary benefit lies in enhancing the accuracy and safety of drilling operations. Firmly securing the workpiece reduces the risk of accidents and ensures that holes are drilled exactly where intended. This accuracy is particularly crucial when working on delicate or expensive materials.

The clamp's ability to hold irregularly shaped objects and prevent them from spinning or vibrating during drilling contributes to cleaner and more precise results.

It saves time by eliminating the need for manual holding or additional assistance, enabling users to work independently. In summary, the Drill Press Clamp is a versatile tool that enhances precision and safety, making it an invaluable asset for professionals and hobbyists alike.

10. Edge Clamps

Edge clamps are versatile mechanical devices designed to securely hold workpieces in place along their edges during various machining, welding, or assembly processes. These clamps typically consist of a sturdy body with a clamping mechanism that exerts pressure on the workpiece's edge, ensuring a firm grip. They are commonly used in metalworking, woodworking, and manufacturing industries.

Edge clamps come in various designs, including C-clamps, bar clamps, and quick-action clamps, catering to different applications and workpiece sizes. Their characteristics often include adjustable clamping force, quick setup and release mechanisms, and durable construction materials, such as steel or aluminum, to withstand the rigors of industrial use.

Ideal uses of edge clamps are prevalent in scenarios where precise alignment and secure fastening of workpieces are crucial. They are highly beneficial when working with irregularly shaped or delicate materials that may be prone to damage from traditional clamping methods.

Edge clamps excel in tasks like edge milling, routing, or bonding, where maintaining a uniform edge distance is essential. They are also valuable for securing workpieces in tight spaces where conventional clamps may not fit.

The benefits of edge clamps include improved efficiency and accuracy in machining and assembly processes, reduced workpiece deformation risk, and enhanced operator safety. These clamps enable artisans and manufacturers to achieve higher-quality results while ensuring the integrity of their workpieces.

11. Face clamps

Face clamps are essential tools in woodworking and metalworking, designed to securely hold workpieces in place during various machining and assembly processes. These clamps typically feature a robust and straightforward design consisting of a fixed jaw and a movable jaw that can be adjusted to accommodate workpieces of varying sizes. The fixed jaw is anchored to a sturdy frame, while the movable jaw can be moved along a threaded screw or bar to apply clamping force.

Face clamps often have large, flat jaws with soft, non-marring pads to prevent damage to the workpiece's surface. They are widely used in carpentry, cabinetry, welding, and other precision tasks where securing workpieces is crucial.

Face clamps are ideal for various applications and offer several key benefits. They are particularly useful when aligning and joining pieces during woodworking or metalworking projects, ensuring precise and stable connections.

These versatile clamps can be employed in various orientations, allowing for horizontal and vertical clamping. They excel in gluing, edge joining, and assembling parts with accuracy and consistency.

Face clamps provide the added advantage of freeing up both hands of the operator, enhancing safety and productivity. Their ability to firmly hold workpieces reduces the likelihood of slippage or misalignment, resulting in cleaner, more professional results.

Whether you are a professional tradesperson or a DIY enthusiast, face clamps are indispensable tools that contribute to the success and quality of your projects.

12. Flooring Clamp

A flooring clamp is a versatile tool designed for use in the construction and flooring industry. It typically consists of two clamping jaws connected by a sturdy handle or lever mechanism. These clamps are primarily used for securing and aligning flooring materials during installation, such as hardwood planks, laminate, or tiles.

The design of a flooring clamp allows for precise control and pressure adjustment, ensuring a tight and even fit between flooring pieces. They often feature durable construction with rubberized or non-marring surfaces on the clamping jaws to prevent damage to the flooring material.

Some models may incorporate leveling or leveling mechanisms to ensure the flooring remains flat and flush. Flooring clamps may have ergonomic handles for comfortable use and can be used in various orientations to accommodate different installation angles.

Ideal for both professional and DIY applications, flooring clamps offer several benefits. They facilitate efficient and accurate installation, reducing gaps and ensuring a seamless finish.

Flooring clamps are particularly useful when working with larger, heavier materials or when precise alignment is critical, such as in herringbone or diagonal installations. They help prevent excessive tapping or hammering, reducing the risk of damaging the flooring material.

These clamps promote safety by holding materials firmly in place, minimizing the potential for tripping hazards or uneven surfaces. Overall, using flooring clamps results in a more efficient, precise, and aesthetically pleasing installation process, making them an indispensable tool for flooring professionals and enthusiasts alike.

13. Hammered-metal clamps

Hammered-metal clamps are a versatile and robust fastening solution renowned for their durability and effectiveness in various applications. These clamps are typically constructed from high-quality metal alloys such as steel or aluminum, which are precisely shaped and hammered to create a textured surface. This hammered texture adds to their aesthetic appeal and enhances their grip and resilience.

The design of these clamps features a tightening mechanism, usually a screw or lever, allowing users to fasten objects together securely. They come in various sizes and configurations to accommodate a wide range of materials and purposes.

Ideal for industrial and domestic use, hammered metal clamps hold objects firmly in place, offering stability and reliability. Their benefits are manifold, providing a secure and adjustable grip and ensuring that items stay firmly connected or in position.

These clamps are often employed in woodworking, metalworking, construction, and automotive industries, where their strength and resilience are crucial. They find utility in DIY projects and home repairs, making them a valuable tool for homeowners and hobbyists alike. The hammered metal finish adds a touch of craftsmanship and helps prevent slippage, making them an indispensable component in the toolkit of anyone seeking dependable and long-lasting fastening solutions.

14. Hand Screw Clamps

Hand Screw Clamps are versatile and indispensable tools in woodworking and other applications. These clamps typically consist of two wooden or metal jaws, a threaded screw mechanism, and a handle. The jaws are designed to hold workpieces securely, and the screw mechanism allows for precise adjustment of clamping pressure.

Hand Screw Clamps are known for their simple yet effective design, making them easy to use even for beginners. They come in various sizes to accommodate different workpiece dimensions and are often made with durable materials such as cast iron or hardwood. Their threaded screw can be turned to tighten or release the clamping pressure, ensuring a firm grip on the workpiece.

Ideal for woodworking, cabinetry, and other crafts, Hand Screw Clamps offer several benefits. They excel in delicate operations where a gentle but secure hold is required, preventing damage to fragile materials. Their wide jaws distribute pressure evenly, reducing the risk of marring the workpiece's surface. Additionally, their adjustable nature allows for precise control over the clamping force, making them suitable for various project sizes and shapes.

Hand Screw Clamps are also favored for their longevity, as they are built to withstand heavy use. They are essential in any workshop, providing stability and accuracy during various tasks, from gluing and assembly to intricate joinery.

15. Hold-Down Clamps

Hold-down clamps are essential components in various machining and workholding applications. These clamps are designed to securely fasten workpieces to a worktable or fixture, preventing movement or vibration during machining, welding, or assembly processes.

Typically constructed from durable materials like steel or aluminum, hold-down clamps come in various designs, including toggle, vertical, and horizontal clamps, each tailored to specific applications.

They typically feature a lever or handle that can be easily operated to engage or disengage the clamp, allowing for quick and efficient workpiece positioning and removal.

Hold-down clamps often incorporate adjustable features, such as threaded screws or sliding mechanisms, enabling precise control over clamping force and workpiece thickness compatibility.

Hold-down clamps find ideal use in various industries and tasks where workpiece stability is crucial. In woodworking, metalworking, and CNC machining, they ensure workpieces remain firmly in place, enhancing safety and precision.

These clamps are also commonly used in welding to secure components during welding, reducing the risk of distortion or misalignment. In assembly lines, hold-down clamps facilitate consistent and efficient assembly of parts, streamlining production processes.

The benefits of hold-down clamps include improved workpiece accuracy, reduced material wastage due to fewer errors, enhanced operator safety by minimizing the risk of accidents caused by shifting workpieces, and increased productivity through faster and more stable machining or assembly operations.

Hold-down clamps are indispensable tools that contribute to better quality and efficiency in various manufacturing and fabrication tasks.

16. Kant-Twist Clamp

The Kant-Twist Clamp is a versatile and efficient clamping device designed for various applications. Its unique design consists of a threaded rod with a rotating handle and a clamping pad at one end. To use the clamp, you simply twist the handle, which moves the clamping pad along the threaded rod, allowing you to quickly and securely hold objects in place.

The Kant-Twist Clamp is known for its durability and ease of use, making it a popular choice in various industries, including woodworking, metalworking, welding, and manufacturing.

The Kant-Twist Clamp offers numerous benefits and is ideal for holding materials firmly in place during machining or fabrication processes. First and foremost, it provides a strong and reliable grip, preventing workpieces from shifting or slipping during critical operations.

The clamp's quick and tool-free operation saves time and effort, improving workflow efficiency. Its versatility allows for various clamping positions, making it adaptable to different project requirements.

The Kant-Twist Clamp is designed to minimize marring or damage to the workpiece's surface, ensuring a clean and professional finish. Overall, this clamp is an indispensable tool for professionals and hobbyists alike, enhancing precision and safety in a wide range of applications.

17. Locking clamp

A Locking Clamp is a versatile and practical mechanical tool designed for securely holding objects or materials in place through controlled pressure.

Typically constructed from durable materials like steel or aluminum, a locking clamp features a pair of opposing jaws, one fixed and one adjustable, operated by a threaded screw mechanism or a quick-release lever. The adjustable jaw can be tightened or released to firmly grip objects of various sizes and shapes, providing a dependable and customizable holding solution.

Locking clamps often incorporate rubber or non-slip grips on their handles for ergonomic and comfortable operation, ensuring user convenience.

Ideal for a wide range of applications, locking clamps are essential tools in woodworking, metalworking, welding, automotive repair, and even in DIY home projects. They securely hold workpieces during sawing, drilling, gluing, or welding, enabling precision and stability.

Locking clamps are invaluable for holding parts in place during assembly, assisting in alignment, and preventing accidents caused by slipping or shifting materials.

Their benefits include enhanced safety, improved work efficiency, and the ability to free up both hands for intricate tasks, making them indispensable in various professional and hobbyist settings.

Whether in a workshop or at home, locking clamps prove themselves as reliable tools that simplify tasks and contribute to the quality of workmanship.

18. Miter Clamps

Miter clamps are versatile woodworking tools designed to securely hold two pieces of material, typically at a 45-degree angle, forming a precise miter joint. These clamps are essential for various woodworking and carpentry projects where accurate and clean angles are crucial.

Miter clamps typically feature a compact, lightweight design, making them easy to maneuver and position on the workpiece. They often incorporate a spring-loaded mechanism or a threaded screw for adjusting the clamping pressure to ensure a snug fit between the two pieces being joined.

Miter clamps may have soft or non-marring pads to protect the workpiece's surface from damage during clamping.

Miter clamps offer several benefits, ideal for tasks such as picture framing, crown molding, and creating clean corners in furniture and trim work.

Firstly, they provide a quick and efficient way to hold mitered pieces securely in place, preventing them from shifting during glue-up or assembly. This leads to more precise and professional-looking results.

Secondly, miter clamps eliminate the need for complex setups and jigs, saving time and effort. Their adjustability allows for easy alignment and adjustment, ensuring perfect corner joints.

Additionally, these clamps are invaluable when working with delicate or fragile materials that could be damaged by excessive clamping pressure.

Overall, miter clamps are essential for achieving seamless miter joints and enhancing the quality of woodworking and carpentry projects.

19. Picture Frame Clamp

The Picture Frame Clamp is a versatile and essential tool for woodworking and framing enthusiasts. This clamp is designed with precision and efficiency, featuring a sturdy metal frame with adjustable clamping jaws.

Its primary purpose is to securely hold together the corners of picture frames during assembly, ensuring perfect alignment and a seamless finish. The clamping jaws can be adjusted to accommodate various frame sizes, and the pressure can be easily regulated to prevent damage to delicate materials.

The ergonomic handle and quick-release mechanism make it user-friendly and time-saving, allowing for effortless frame assembly.

Ideal for professional framers, artists, and DIY enthusiasts, the Picture Frame Clamp offers several benefits.

Firstly, it ensures precise and tight corner joints, eliminating the need for additional fasteners or adhesives. This results in clean, professional-looking frames that enhance the presentation of artwork or photographs.

Additionally, the clamp's ease of use reduces assembly time and minimizes the chances of errors, making it a valuable tool for anyone involved in framing projects.

Its versatility allows for use with various frame materials, such as wood, metal, or plastic, making it a must-have for anyone seeking to create custom frames with ease and precision.

Overall, the Picture Frame Clamp streamlines the framing process, making it more efficient and enjoyable while delivering outstanding results.

20. Pinch Dog Clamp

The Pinch Dog Clamp is a versatile and indispensable tool used in woodworking and carpentry for securing workpieces during various woodworking tasks.

This clamp features a simple yet effective design, consisting of a pair of wooden jaws connected by a threaded metal rod. The jaws are typically serrated to provide a strong grip on the workpiece without damaging its surface.

To use the Pinch Dog Clamp, woodworkers insert one jaw into a pre-drilled hole in the workpiece while the other jaw is positioned on the opposite side. As the metal rod is tightened, the jaws pinch the workpiece securely, ensuring it remains stable and immobile while tasks like gluing, routing, or carving are performed. The wooden construction of the jaws minimizes the risk of marring or denting delicate wood surfaces, making it a favored choice for woodworking projects.

Ideal for tasks requiring precise and stable workpiece fixation, the Pinch Dog Clamp offers several benefits.

Firstly, it provides an excellent alternative to traditional clamps and vises, as it doesn't obstruct access to the work surface and allows for easy manipulation of the piece.

Additionally, it excels in securing irregularly shaped or curved workpieces, ensuring a reliable hold even on intricate projects. Its non-marring grip prevents damage to the workpiece, preserving the quality of the wood.

Furthermore, the Pinch Dog Clamp is known for its durability and longevity, as it is constructed from sturdy materials that withstand the rigors of woodworking. This tool is a must-have for woodworkers seeking precision, versatility, and damage-free workpiece clamping.

21. Pipe Clamps

Pipe clamps are mechanical devices designed to securely fasten and support pipes in various industrial and construction applications.

They are typically composed of a few key components, including a U-shaped clamp with threaded ends and a screw or bolt mechanism. The U-shaped clamp wraps around the pipe while the screw or bolt is tightened to create a tight grip, preventing the pipe from moving or sagging.

Pipe clamps come in various materials, such as steel or aluminum, and sizes to accommodate different pipe diameters. Their design allows for easy installation and adjustment, making them a versatile solution for holding pipes in place.

Pipe clamps find ideal uses in various applications, primarily in the plumbing, HVAC (heating, ventilation, and air conditioning), and construction industries.

They are essential for securing pipes to walls, ceilings, or other surfaces, ensuring stability, and preventing leaks or damage.

Pipe clamps provide several benefits, including cost-effectiveness, as they are inexpensive and require minimal maintenance. They also offer flexibility in adjustment, making it easy to align and level pipes accurately.

Pipe clamps help maintain the integrity of pipe systems, reducing the risk of leaks and enhancing the overall safety and efficiency of plumbing and HVAC installations.

22. Pneumatic Clamps

Pneumatic clamps are versatile mechanical devices that securely hold and fasten objects in various industrial applications.

These clamps operate on compressed air, using pneumatic pressure to engage and disengage their gripping mechanisms.

Typically, pneumatic clamps consist of a sturdy housing, a piston or actuator, and a gripping element such as jaws or fingers.

The design of pneumatic clamps allows for quick and precise clamping, making them ideal for tasks that require fast and reliable fixture changes.

They are commonly used in manufacturing processes, welding, machining, and assembly lines where holding workpieces securely and efficiently is crucial.

Pneumatic clamps come in various configurations, including toggle, swing, and straight-line clamps, offering adaptability to different workpiece shapes and sizes.

Additionally, they are known for their durability, ease of maintenance, and the ability to provide consistent clamping force, contributing to improved productivity and product quality in industrial settings.

Pneumatic clamps find ideal use in a wide range of industries and applications. Their benefits include increased efficiency, reduced labor costs, and enhanced safety.

These clamps excel in tasks requiring rapid workpiece positioning and repetitive clamping, automating processes and reducing the risk of operator fatigue or injury.

Their quick response times and consistent clamping force ensure precise and repeatable results, essential in industries like automotive manufacturing, where tight tolerances are crucial.

Furthermore, pneumatic clamps enhance workplace safety by minimizing the need for manual clamping and reducing the chances of accidents.

In summary, pneumatic clamps' versatility, speed, and reliability make them indispensable tools for improving productivity and safety across various industrial sectors.

23. Pony Clamps

Pony Clamps are versatile and indispensable tools in woodworking and metalworking. These clamps are designed with precision and durability in mind, featuring a robust construction that ensures a secure and reliable grip on materials.

Their unique design incorporates a sliding jaw mechanism, allowing quick and effortless adjustments to accommodate various workpiece sizes.

Pony Clamps are characterized by their ergonomic handles that provide a comfortable grip for extended periods of use, minimizing hand fatigue. Their coated steel or cast iron bodies are built to withstand heavy-duty applications, making them ideal for woodworking, welding, and metal fabrication tasks.

Ideal uses and benefits of Pony Clamps encompass a wide array of applications. These clamps are perfect for securely holding materials in place during cutting, drilling, gluing, or welding, ensuring precise and consistent results. Their versatility extends to woodworking projects, where they excel at clamping together pieces for seamless joinery.

Pony Clamps provide stability and accuracy when aligning and assembling metal components in metalworking. Their quick-adjust feature saves valuable time during intricate projects.

Pony Clamps are an essential addition to any workshop, offering reliability, durability, and ease of use to artisans and DIY enthusiasts alike, enhancing their work's overall quality and efficiency.

24. Quick-Release Clamps

Quick-release clamps, also known as quick-action clamps or quick-release toggle clamps, are versatile and efficient tools designed to securely hold objects or workpieces in place while allowing for rapid and convenient adjustment and release.

These clamps typically consist of a handle, a clamping mechanism, and a clamping pad or jaw. The design incorporates a quick-release lever or button that, when activated, disengages the clamping force, enabling swift repositioning or removal of the workpiece.

Quick-release clamps are commonly constructed from sturdy materials like steel or aluminum, ensuring durability and stability during various applications.

They come in a variety of sizes and styles to accommodate different workpiece shapes and sizes, making them invaluable tools in woodworking, metalworking, welding, and other industrial or DIY projects.

Quick-release clamps find ideal use in situations where the rapid securing and adjustment of workpieces are crucial. They are invaluable for woodworking tasks such as securing boards or panels during cutting, routing, or assembly. In metalworking, these clamps hold metal pieces steady during welding, grinding, or machining operations.

Quick-release clamps are commonly used in the automotive industry to fix parts during repair or assembly. Their primary benefit lies in their time-saving capabilities, as they allow for swift and tool-free adjustments, reducing downtime and improving workflow efficiency.

Quick-Release Clamps enhance safety by securely holding workpieces in place, preventing slippage and potential accidents. Their versatility and ease of use make them indispensable tools for professionals and hobbyists in various applications.

25. Specialty Clamps

Specialty clamps are versatile tools designed to meet specific and unique clamping needs in various industries and applications. These clamps are engineered with precision to offer tailored solutions for specialized tasks.

Their design varies widely depending on the intended use, but common characteristics include robust construction, adjustable mechanisms, and specialized features such as swivel jaws, quick-release mechanisms, or unique shapes.

Specialty clamps are typically made from high-quality materials like stainless steel or heavy-duty plastics, ensuring durability and longevity. Their designs often incorporate ergonomic handles and grips for comfortable and efficient operation.

These clamps come in various sizes and configurations, from miniature precision clamps for delicate work to heavy-duty industrial clamps capable of exerting substantial pressure.

Specialty clamps find their ideal uses across many industries and scenarios, offering several key benefits. In woodworking, specialty clamps like edge and band clamps excel in precise joinery and panel assembly. In metalworking, welding and toggle clamps provide secure and stable workholding during fabrication. The medical field relies on specialty clamps for surgical procedures, ensuring precision and safety.

Specialty clamps are indispensable in the automotive industry, aerospace applications, and electronics manufacturing, where they aid in securing components during assembly. Their versatility and adaptability make them invaluable when standard clamps fall short.

These clamps enhance efficiency, accuracy, and safety, making them indispensable tools in specialized fields and industries.

26. Speed Clamps

Speed Clamps are versatile and efficient tools designed for securely fastening and holding objects during various tasks, such as woodworking, metalworking, or construction.

They typically consist of a sturdy metal or plastic body with an adjustable jaw mechanism that can quickly and easily tighten or release. The jaw often has serrated teeth or rubberized grips to provide a firm, non-slip hold on the workpiece.

Speed Clamps come in various sizes and styles, including bar, C, and quick-release clamps, allowing flexibility in accommodating different project requirements. They are known for their durability and ease of use, making them a staple tool in workshops and job sites.

Some Speed Clamps feature ergonomic handles for comfortable operation, and many are designed with a one-handed operation capability, enhancing their efficiency.

Speed Clamps are indispensable tools in a wide range of applications. They excel in tasks that require temporary or permanent fastening and holding of materials.

Woodworkers often rely on Speed Clamps to secure boards or panels during gluing, ensuring precise and tight joints. In metalworking, these clamps are essential for securing workpieces in place for cutting, welding, or drilling. They are invaluable for temporarily holding framing components or securing fixtures during installations.

The primary benefits of Speed Clamps include their quick and easy adjustment, which saves valuable time on projects, their ability to provide a strong and reliable grip, and their versatility, allowing users to work with various materials and sizes.

Speed Clamps also promote safety by preventing workpieces from shifting or slipping during critical tasks, improving craftsmanship and project efficiency.

27. Spring Clamps

Spring clamps are versatile and compact tools commonly used in various applications. They feature a straightforward yet efficient design, consisting of two hinged arms with jaws that are spring-loaded for easy opening and closing. The jaws are typically covered with non-marring pads to protect the workpiece from damage.

Spring clamps are designed to provide a firm and secure grip on materials such as wood, plastic, metal, or fabric. They are known for their ease of use, making them suitable for holding workpieces together during gluing, clamping down on temporary fixtures, or securing items in place during assembly or repair tasks. Their lightweight and portable nature makes them convenient for professional and DIY projects.

Ideal for a wide range of applications, spring clamps offer several benefits. They are particularly useful in woodworking, where they can hold pieces together while the glue dries, ensuring a strong bond.

In photography, spring clamps can be employed to secure backdrops or modifiers to achieve the desired lighting setup. These clamps are also handy for temporarily holding parts during repairs in the automotive industry.

Their affordability and accessibility make them valuable to any toolkit, offering quick and reliable clamping solutions for various tasks.

Overall, spring clamps are indispensable tools that simplify work in diverse fields and provide efficient, temporary clamping with ease of use and cost-effectiveness.

28. Step Clamps

Step clamps are versatile and essential tools in various machining and manufacturing processes. These clamps are designed with a stepped profile featuring multiple gripping points along their length.

Typically made from durable materials such as steel or aluminum, step clamps are designed to hold workpieces in place during machining operations. Their characteristic stepped shape allows for adjustable clamping, making them suitable for various workpiece sizes and shapes.

Step clamps often feature threaded holes or slots for easy attachment to fixtures and workbenches, enhancing their stability and usability in precision applications.

These clamps are known for their reliability, durability, and precision, making them indispensable in metalworking, woodworking, and automotive manufacturing industries.

Step clamps find ideal use when workpieces of varying sizes and shapes need to be firmly held during machining or assembly processes. Their ability to provide secure and adjustable clamping makes them particularly valuable for milling, drilling, welding, and assembly tasks.

These clamps offer several benefits, including improved workpiece stability, reduced setup time, and enhanced safety by preventing workpiece movement or vibration. Step clamps also allow efficient use of the workspace and offer cost-effectiveness due to their reusability and durability.

In summary, step clamps are versatile tools crucial in achieving precision and efficiency in various manufacturing and machining applications.

29. Toggle Clamps

Toggle clamps are versatile mechanical devices designed to securely hold objects in place, providing quick and efficient clamping and releasing.

These clamps typically consist of a handle, a clamping arm, a pivot point, and a base. When the handle is squeezed, the clamping arm moves to exert pressure on the workpiece, holding it firmly in position.

Toggle clamps come in various designs, including vertical, horizontal, push-pull, and latch-action variants, each suited for specific applications. They are often made from durable materials such as steel or stainless steel to withstand heavy loads and harsh working conditions.

The key characteristics of toggle clamps include their reliability, ease of use, and the ability to generate high clamping forces with minimal effort, making them a valuable tool in various industries.

Toggle clamps find ideal uses in various applications across woodworking, metalworking, welding, machining, and assembly processes. Their benefits include quick and precise clamping, reducing the need for manual force, and enabling consistent results.

Toggle clamps enhance safety by securely holding workpieces, minimizing the risk of accidents. They also save time and effort by speeding up repetitive clamping tasks, increasing productivity.

These clamps offer repeatability and reliability, ensuring the clamping force remains consistent over multiple operations. Toggle clamps are essential for professionals seeking to improve efficiency, accuracy, and safety.

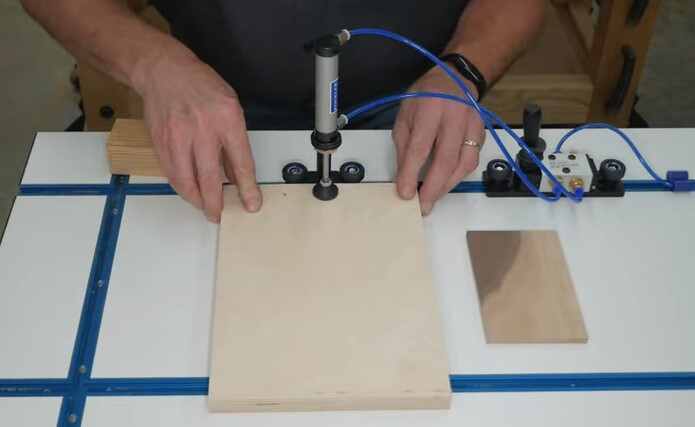

30. Vacuum Clamps

Vacuum clamps are innovative tools used in various industries for securing workpieces during machining, woodworking, and other precision tasks.

These clamps operate on the principle of creating a vacuum seal between the workpiece and the clamp's surface, ensuring a secure and stable hold without the need for traditional clamps or fixtures.

Typically, vacuum clamps have a flat, sturdy base with a porous or rubberized surface. A vacuum pump or source is connected to the base, generating negative pressure to create the seal.

Some vacuum clamps are designed with adjustable suction levels to accommodate different materials and workpiece sizes. They often have sensors to monitor and maintain the vacuum pressure, ensuring consistent and reliable clamping.

Vacuum clamps can be integrated into CNC machines and robotic systems, enhancing automation capabilities and precision in manufacturing processes.

Vacuum clamps find ideal use in tasks where traditional clamping methods may be impractical or hinder precision. These clamps hold delicate or irregularly shaped workpieces, such as thin sheets of metal, glass, or composite materials, without leaving marks or causing damage.

Woodworkers, metalworkers, and manufacturers in the aerospace and automotive industries benefit from vacuum clamps when machining intricate parts or creating prototypes.

The key advantages of vacuum clamps include enhanced versatility, reduced setup time, and improved accuracy. They enable efficient batch production, reduce material wastage, and minimize the need for manual repositioning.

Vacuum clamps contribute to a safer work environment by eliminating protruding clamps or fixtures that could pose hazards.

Overall, vacuum clamps represent a cutting-edge solution for securing workpieces in various applications, promoting efficiency and precision in various industries.

31. Wire Rope Clamps

Wire rope clamps, or wire rope clips or cable clamps, are essential hardware components used in various applications to secure and terminate wire ropes and cables.

These clamps typically have a U-shaped or saddle-shaped body with two threaded bolts and nuts. To use them, the wire rope is looped around an anchor point or another section of the rope, and the two ends are then brought together and inserted through the U-shaped body. The bolts are tightened with nuts to create a firm grip on the wire rope, preventing it from slipping or unraveling.

Wire rope clamps are commonly made of stainless steel, galvanized steel, or aluminum to ensure durability and corrosion resistance, making them suitable for indoor and outdoor use.

Their design allows for easy installation without requiring specialized tools, making them a versatile and cost-effective solution for securing wire ropes in various applications.

Wire rope clamps find ideal uses in numerous industries and scenarios. They are particularly valuable in construction and rigging, where they are used to create eye loops or secure wire rope ends to anchors, hooks, or other fittings. These clamps are also commonly employed in marine and maritime applications to fasten rigging and lifelines, ensuring safety and stability on boats and ships.

They are essential in agriculture and forestry for applications like fencing and general maintenance and repair tasks.

The benefits of wire rope clamps include their simplicity of use, reusability, and reliability in providing a secure connection, which contributes to enhanced safety and efficiency in various industries. Their versatility and cost-effectiveness make them valuable tools for professionals and DIY enthusiasts.

Factors to consider when choosing the right clamp

Choosing the right clamp for a particular application is essential to ensure safety, efficiency, and effectiveness. The choice of clamp depends on various factors, including the specific task and the materials involved. Here are some key factors to consider when choosing the right clamp:

1. Material Compatibility:

Ensure that the clamp material is compatible with the materials being clamped. For example, if you're working with corrosive substances, use clamps of materials that resist corrosion.

2. Load Capacity:

Determine the maximum load or weight that the clamp will need to support. Choose a clamp that can handle the required load without deformation or failure.

3. Clamp Type:

Various types of clamps are available, such as C-clamps, bar clamps, spring clamps, toggle clamps, pipe clamps, and more. Select the type that best suits your application and workspace.

4. Clamping Mechanism:

Consider the clamping mechanism, such as screw-type, quick-release, or squeeze-handle mechanisms, depending on the ease of use and the specific task requirements.

5. Jaw Configuration:

Different clamps have different jaw configurations, such as parallel jaws, swivel jaws, and V-shaped jaws. Choose the jaw design that provides the best grip and stability for your application.

6. Throat Depth:

Throat depth is the distance from the clamp's jaws to the screw or handle. Select a clamp with an appropriate throat depth to reach the desired location on your workpiece.

7. Clamping Pressure:

Consider the amount of clamping pressure required. Some clamps have adjustable pressure settings, while others have fixed pressure. Ensure the clamp can generate the necessary force.

8. Size and Dimensions:

Take into account the size and dimensions of the clamp. Ensure it can fit within the available workspace and accommodate the size of the materials you need to clamp.

9. Ergonomics:

Consider the comfort and ergonomics of using the clamp, especially if it will be used frequently or for extended periods. Look for features like padded handles or ergonomic grips.

10. Durability and Quality:

Invest in high-quality clamps made from durable materials, as they will likely last longer and perform better in the long run.

11. Specialized Features:

Some clamps have specialized features like swivel pads and quick-release or ratcheting mechanisms. Assess whether such features are necessary for your application.

12. Budget:

Determine your budget for clamps and choose options that offer the best value for your needs.

13. Safety:

Ensure that the clamp design and operation are safe for your intended application. Clamps should not pose any risk of injury when used correctly.

14. Environmental Conditions:

Consider the environmental conditions where the clamp will be used, such as temperature, humidity, and chemical exposure. Choose clamps that can withstand these conditions.

15. Maintenance:

Evaluate the ease of maintenance and cleaning for the chosen clamp. Some clamps may require regular lubrication or cleaning to ensure optimal performance.

By carefully considering these factors, you can select the right clamp for your specific task, ensuring efficiency, safety, and long-term functionality.

Maintaining and Storing Woodworking Clamps

Maintaining and storing woodworking clamps is essential to ensure they remain in good working condition and last long. Proper care and storage will also make accessing and using them easier when needed. Here are some tips on how to maintain and store your woodworking clamps:

Maintenance:

1. Clean After Use:

After using your clamps, wipe off any dust, dirt, or glue residue. This prevents buildup that can affect the clamp's performance over time.

2. Check for Damage:

Inspect your clamps for any signs of damage, such as bent or misaligned jaws, loose components, or rust. Address any issues promptly to prevent further damage.

3. Lubricate Moving Parts:

Lubricate the moving parts, such as the screw threads and handles, with a light machine oil or silicone spray. This helps to keep them operating smoothly.

4. Tightness:

Periodically check the tightness of nuts, bolts, and screws on your clamps. If they become loose, tighten them to maintain the clamp's stability.

5. Rust Prevention:

If your clamps are made of metal, prevent rust by storing them in a dry environment and applying a rust-inhibiting coating to the metal parts.

Storage:

1. Organize by Type:

Group your clamps by type and size, such as bar clamps, pipe clamps, or C-clamps. This makes locating the specific clamp you need for a project easier.

2. Hang on a Wall:

Installing wall-mounted racks or hooks specifically designed for clamps is an excellent way to store them. Hanging clamps vertically keeps them easily accessible and prevents clutter.

3. Use a Clamp Cart:

If you have a substantial collection of clamps, consider using a clamp cart with built-in racks or shelves. This allows you to move them around your workspace as needed.

4. Protective Pads:

To prevent damage to the clamp pads, consider adding foam or rubber pads to the jaws or using clamp protectors when storing them.

5. Store Flat:

If hanging is not an option, lay your clamps flat on shelves or drawers. Ensure they are not stacked on each other, as this can cause damage to the pads or mechanisms.

6. Label or Tag:

Consider labeling or tagging your clamps with their size and type. This makes it easier to find the right clamp quickly.

7. Climate Control:

Store your clamps in a climate-controlled area to prevent moisture-related damage. Extremes of temperature and humidity can cause rust or warping.

8. Keep Them Clean:

Ensure the storage area is clean and free of sawdust and debris. Regularly clean the storage space to prevent contamination of your clamps.

By following these maintenance and storage tips, you can keep your woodworking clamps in excellent condition, making your woodworking projects more efficient and enjoyable. Properly cared for clamps will serve you well for many years.

Conclusion

In conclusion, woodworking clamps are indispensable tools that every woodworker should have in their arsenal. They come in a variety of types, each designed for specific tasks and applications. From the versatile and widely used bar clamps to the specialized edge clamps and pipe clamps, there's a clamp for nearly every woodworking need.

Understanding the different types of woodworking clamps and their uses is essential for both beginners and experienced woodworkers. Choosing the right clamp for the job can make a significant difference in the quality and precision of your woodworking projects.

Whether you're assembling a cabinet, gluing up a tabletop, or simply holding pieces together while the glue dries, the right clamp can ensure that your project comes together smoothly and accurately. So, take the time to familiarize yourself with the various types of clamps, invest in a quality set, and watch your woodworking skills and craftsmanship improve. With the right clamps at your disposal, the possibilities in the world of woodworking are virtually limitless. Happy woodworking!