To use parallel clamps for woodworking, align the wood pieces, place the clamps evenly along the joint, and tighten the handles simultaneously. Ensure even pressure for a secure bond. Release after the glue dries.

Unlock the potential of your woodworking projects with parallel clamps – the unsung heroes of precision and efficiency. If you're a woodworking novice, navigating the vast array of tools can be overwhelming. Fear not! In this guide, we'll demystify the world of parallel clamps, offering beginners a step-by-step walkthrough on how to harness their power. From understanding the basics to mastering advanced techniques, discover how these versatile tools can elevate your woodworking skills and ensure seamless, sturdy joins. Let's embark on a journey to make your woodworking endeavors smoother and more precise!

This guide is for you if you're looking for a quick and easy way to hang your parallel clamps. You can have your clamps securely hung on any wall or surface in just a few simple steps.

First, start by finding a suitable location to hang your clamps. Ensure that the chosen spot is strong enough to support the weight of the clamps and that there is nothing in the way that could prevent the clamps from hanging correctly. Once you've found the perfect spot, mark where you'll need to drill holes for the screws.

Next, create pilot holes at your marked locations using a drill and the appropriate size bit. Be sure not to drill too deeply, as you don't want to damage any wiring or pipes behind the wall.

With the pilot holes drilled, it's time to start screwing in the screws. Again, be careful not to over-tighten, as this could strip the threads or damage the wall. Once all the screws are in place, carefully hang your clamps on them.

And that's it! You should now have a secure place to hang your parallel clamps. With a little bit of care, they should give you years of trouble-free use.

Related: Find out what types of woodworking clamps are available and how they can be used

What application would you use parallel clamps for on a woodworking project?

If you're looking for a way to add speed and efficiency to your woodworking projects, you might consider using parallel clamps. Parallel clamps are designed to be used in pairs, with one clamp attached to each side of the workpiece. This allows even pressure to be applied to the workpiece, which can help ensure a more consistent and professional finish.

There are several applications for parallel clamps, and they can be used for various woodworking projects. Here are just a few examples:

1. Gluing:

When gluing wood together, applying even pressure to the entire surface area is essential to create a strong bond. Parallel clamps can help to ensure that the glue is evenly distributed, resulting in a stronger bond.

2. Edge Jointing:

The joint must be flush and even when joining two pieces of wood together at the edge. Parallel clamps can help hold the workpieces in place while you work, ensuring the joint is level and flush.

3. Mortise and Tenon Joints:

Mortise and tenon joints are popular in furniture making. They are strong and durable but can be tricky to get right. Parallel clamps can help ensure the joint is correctly aligned before the glue sets.

4. Cabinet Making:

Cabinet making often requires working with large pieces of wood that need to be cut to size and then attached. Parallel clamps can help hold the pieces in place while you work, ensuring that they are cut to the correct size and aligned.

5. Woodturning:

When turning wood on a lathe, it's essential to have even pressure applied to the workpiece to create a smooth finish. Parallel clamps can help to ensure that the wood is evenly supported while you work, resulting in a better-finished product.

How to use parallel clamps? A Beginners Guide

Parallel clamps are versatile and essential tools for woodworking, cabinetry, and other applications where you need to securely hold two pieces of material together in parallel. They are known for their strength and stability. Here's a beginner's guide on how to use parallel clamps effectively:

1. Safety First:

Always wear appropriate safety gear, including safety glasses and hearing protection when working with power tools.

2. Select the Right Size:

Parallel clamps come in various sizes, typically ranging from 12 inches to 50 inches or more. Choose a clamp size that suits the size of your project.

3. Inspect the Clamp:

Before using a parallel clamp, inspect it for any damage or defects. Make sure the clamp is in good working condition.

4. Prepare Your Workpieces:

Ensure that the two pieces you want to clamp together are properly prepared. They should be flat and aligned, with any glue joints or connections well-fitted and free of debris.

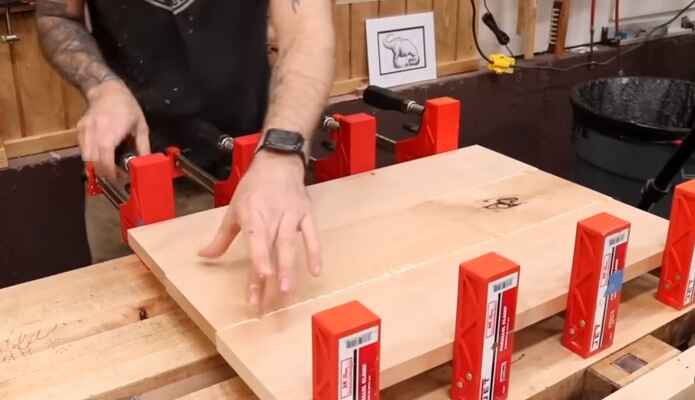

5. Position the Clamps:

Place the clamps on the workpiece with the jaws facing the material you want to clamp. Make sure they are parallel to each other and evenly spaced along the length of the workpiece.

6. Adjust the Clamping Distance:

Many parallel clamps have a mechanism to adjust the clamping distance. To do this, loosen the adjustment knob or handle, slide the movable jaw to the desired position, and then tighten the knob or handle to secure it in place.

7. Apply Even Pressure:

Turn the handle on the clamp to apply pressure evenly across the workpiece. Start with a moderate amount of pressure and gradually increase it until the pieces are securely clamped together. Be careful not to over-tighten, as this can damage the workpiece or the clamp itself.

8. Check for Alignment:

After applying the clamps, check that the workpieces are still aligned correctly. Make any necessary adjustments to ensure they are parallel and in the desired position.

9. Glue Application (If Applicable):

If you are using the clamps for gluing, apply the adhesive to the joint between the workpieces before clamping them together. The even pressure from the parallel clamps will help ensure a strong bond.

10. Drying and Removal:

If you are gluing, allow sufficient time for the adhesive to dry before removing the clamps. Check the manufacturer's instructions for recommended drying times. When removing the clamps, do so slowly and evenly to prevent any sudden shifts in the workpieces.

11. Clean and Store:

After use, clean any excess glue or debris from the clamps, and store them in a dry, cool place to prevent rust or damage.

Remember that parallel clamps are versatile tools and can be used for a wide range of projects. They provide strong, consistent pressure, making them valuable for woodworking, cabinetry, and other tasks that require precise and secure clamping. Practice and experience will help you become more skilled in using these clamps effectively for your specific projects.

What are some common mistakes people make when using parallel clamps?

When it comes to woodworking, one of the essential tools you can have in your arsenal is a set of parallel clamps. These handy tools are necessary for gluing and assembling projects to clamping workpieces together while you drill or saw.

However, as with any tool, there is a right and wrong way to use them. In this article, we'll discuss five of the most common mistakes people make when using parallel clamps and how to avoid them.

1. Not securing the jaws correctly

One of the most common mistakes people make when using parallel clamps is not securing the jaws correctly. The jaws are the part of the clamp that comes into contact with the workpiece, and if they're not adequately secured, they can slip or move during use, resulting in an uneven or poorly clamped joint.

To avoid this, be sure to carefully read the instructions that came with your clamps and follow them to the letter. Additionally, to be safe, it's generally a good idea to apply a small amount of gorilla glue or similar adhesive to the jaws before clamping.

2. Applying too much pressure

Another common mistake people make is applying too much pressure when clamping. It's important to remember that you don't need to tighten the clamp as tight as it will go for it to work correctly. Doing so can damage the workpiece or the clamp itself.

Instead, tighten the clamp until it's snug but not tighter. You should be able to insert a finger between the workpiece and the clamp's jaws without too much resistance.

3. Relying on the clamp to hold things in place

Another common mistake is relying on the clamp to hold things in place while you work. This is particularly common when drilling or sawing, as people often leave the clamped piece unsecured while they go to get their drill or saw.

However, it's important to remember that clamps are not meant to be used as permanent fixtures. They're only meant to hold things in place temporarily, so secure the workpiece to your work surface before starting any cutting or drilling.

4. Not using enough clamps

Another common mistake is not using enough clamps. This is particularly common when gluing up projects, as people often assume one or two clamps will be sufficient. However, it's important to remember that the more surface area you try to glue together, the more clamps you'll need.

A general rule of thumb is to use one clamp for every square foot of surface area you're trying to glue. So, if you're gluing up a four-foot by eight-foot piece of plywood, you'll need at least eight clamps.

5. Not cleaning the clamps after use

Finally, a common mistake people make is not cleaning the clamps after use. This might seem like a small thing, but it's essential.

Clamps, like any other tool, can get dirty and grimy over time, and if they're not cleaned properly, that dirt and grime can transfer to your workpieces, contaminating them.

To avoid this, clean your clamps with a damp cloth after every use. Additionally, applying a light coat of WD-40 or similar lubricant to the clamp's jaws is a good idea before storing them, as this will help prevent rust and corrosion.

By following these simple tips, you can avoid the most common mistakes people make when using parallel clamps. So, get out there and start clamping!

What are some tips for using parallel clamps?

If you're looking for tips on using parallel clamps, you've come to the right place. Here, I'll share seven tips to help you get the most out of your parallel clamps.

1. Make sure the jaws of the clamp are parallel.

This may seem like a no-brainer, but it's essential to check that the clamp's jaws are parallel. If they're not, the clamp will not work correctly.

2. Adjust the jaws to fit the workpiece.

Once you've checked that the jaws are parallel, you'll need to adjust them to fit the workpiece. If the jaws are too far apart, the workpiece will slip; if they're too close together, the clamp won't grip properly.

3. Use clamps of different sizes.

Parallel clamps come in various sizes, so choosing the right size for the job is essential. If you're working with a large workpiece, you'll need a larger clamp; if you're working with a smaller piece, you can get away with a smaller clamp.

4. Consider the type of material you're working with.

The kind of material you're working with will also dictate the size of the clamp you need. If you're working with a soft material like wood, you can get away with a smaller clamp; if you're working with a harder material like metal, you'll need a larger clamp.

5. Use more than one clamp.

If you're working with a large workpiece or an inappropriate material, you may need to use more than one clamp. This will help to ensure that the workpiece is secured correctly and won't slip during the process.

6. Place the clamps strategically.

When placing the clamps on the workpiece, it's crucial to consider where they need to be placed to be most effective. For example, if you're gluing two pieces of wood together, you'll need to place the clamps along the edges so that they can apply pressure to the piece.

7. Use a clamping jig.

A clamping jig is a handy tool that can help you secure your workpiece and prevent it from slipping. There are various clamping jigs available, so choose one that will work best for the job at hand.

By following these tips, you'll be able to get the most out of your parallel clamps and complete your project successfully.

How to use bessey parallel clamps?

Bessey parallel clamps are versatile and useful tools for clamping and securing workpieces during various woodworking and DIY projects. These clamps are known for their parallel jaw design, which allows for even pressure distribution and a secure hold. Here's how to use Bessey parallel clamps effectively:

1. Gather your materials:

- Bessey parallel clamps

- Workpiece to be clamped

- Adequate workspace

2. Choose the right size:

Select a Bessey parallel clamp with a jaw opening that suits your project. Ensure that the clamp can comfortably reach across the workpiece, and the jaw size is appropriate for the thickness of the material you are clamping.

3. Position the workpiece:

Place your workpiece on your work surface, ensuring it is properly aligned and positioned for your project. Make any necessary adjustments or alignments before proceeding.

4. Prepare the clamp:

Ensure the clamp is clean and free from debris that could interfere with its operation.

Check the parallel jaws to ensure they are aligned and parallel. If they are not, you may need to adjust them before use.

5. Open the clamp:

Release the clamp by pressing the trigger or handle release mechanism, depending on the specific Bessey model you have. This will allow the jaws to open fully.

6. Position the clamp:

Position the open jaws of the clamp around your workpiece, ensuring that they are parallel to each other and that the workpiece is centered within the jaws.

7. Close the clamp:

Squeeze the clamp's handle or trigger to close the jaws around the workpiece. The Bessey parallel clamp will apply even pressure along the length of the jaws, securely holding the workpiece in place.

8. Adjust the pressure:

If necessary, you can adjust the clamping pressure by turning the adjustment screw located on the handle or trigger. Tightening the screw will increase the pressure, while loosening it will decrease it.

9. Check alignment:

Double-check that the workpiece remains properly aligned and that the clamp is holding it securely. Make any adjustments as needed.

10. Complete your project:

With the Bessey parallel clamp securely holding your workpiece, you can proceed with your project, whether it involves gluing, cutting, sanding, or any other task that requires a stable work surface.

11. Release the clamp:

When you have finished your project and the adhesive or work is set, release the clamp by pressing the trigger or handle release mechanism. Gently remove the clamp from your workpiece.

Remember to follow safety precautions while working with tools and clamps. Always read and follow the manufacturer's instructions for your specific Bessey parallel clamp model to ensure safe and effective use.

How to use machinist parallel clamps?

Are you tired of dealing with unevenly tightened clamps on your woodworking projects? Do the edges end up wobbly and misaligned? Switch to machinist parallel clamps for a more secure and even hold. Here's a step by step guide on how to use these handy tools:

- Set your project on a flat surface and position the machinist parallel clamp at the edge, making sure the clamp's movable jaw is on the opposite side of where you want it to tighten.

- Turn the adjustment knob clockwise until the movable jaw slightly touches your project's surface.

- Use a measuring tape or ruler to ensure that both fixed and movable jaws are at an equal distance from the edge of your project.

- Once both jaws are even, continue turning the adjustment knob until they securely hold your project in place.

- To release the clamp, turn the knob counterclockwise until it loosens its grip on your project.

Machinist parallel clamps will give you precise and even pressure along your woodworking projects for a professional finish. Give these clamps a try on your next project and see the difference.

How to use irwin parallel clamps?

Irwin parallel clamps are versatile and robust clamping tools that are commonly used in woodworking, metalworking, and various DIY projects. They are designed to provide even pressure across the entire clamping surface and maintain a parallel alignment, making them ideal for gluing, assembling, or securing materials together. Here's how to use Irwin parallel clamps effectively:

1. Select the Right Size:

Irwin parallel clamps come in various sizes and capacities. Choose clamps that are appropriate for your project. Ensure they have a sufficient clamping capacity to accommodate your workpiece.

2. Prepare Your Workpiece:

Before you begin clamping, make sure the surfaces you intend to join are clean, flat, and properly aligned.

3. Position the Clamps:

Decide where you need to apply clamping pressure. Typically, you'll use at least two clamps to distribute the pressure evenly. Position the clamps on either side of the workpiece, making sure they are parallel to each other and perpendicular to the workpiece's surfaces.

4. Adjust the Clamping Jaws:

Irwin parallel clamps have jaws that can be adjusted to fit the thickness of your workpiece. To do this:

- Loosen the jaws: Rotate the handle on one end of the clamp counterclockwise until the jaws are loose.

- Slide the jaws: Move the jaws along the bar to the desired position, ensuring they are centered on the workpiece.

- Tighten the jaws: Rotate the handle clockwise to secure the jaws firmly in place.

5. Apply Clamping Pressure:

Turn the handle on the opposite end of the clamp clockwise to apply pressure to the workpiece. Start with moderate pressure and gradually increase it until the workpiece is securely held in place. Be careful not to overtighten, as this can damage the workpiece or the clamp itself.

6. Check for Parallel Alignment:

Verify that the clamps are holding the workpiece parallel and that the pressure is evenly distributed. Adjust the clamp positions and pressure as needed to achieve the desired alignment.

7. Gluing or Assembling:

If you are using the clamps for gluing, ensure that you have applied the adhesive to the mating surfaces before clamping. Be mindful of glue squeeze-out and have a damp cloth or sponge ready to clean up excess glue.

8. Allow Drying Time:

If you're using the clamps for a glue-up, follow the recommended drying time for your adhesive before removing the clamps.

9. Release the Clamps:

To release the clamps, turn the handle counterclockwise to release the pressure, and then slide the jaws away from the workpiece.

10. Store Properly:

After use, clean any adhesive residue or debris from the clamps and store them in a dry, clean place to prevent rust or damage.

How to use bora parallel clamps?

Are you tired of struggling with traditional clamps that never seem to hold your workpiece securely in place? Look no further than bora parallel clamps.

These revolutionary clamps use parallel clamping technology to distribute pressure evenly, ensuring a secure hold on any material.

But how do you use them? Follow these steps for a successful project every time.

- Determine the size of the bora clamp needed for your project. The bora parallel clamp comes in sizes from 12 to 42 inches.

- Assemble the bora clamp by attaching the movable jaws to the fixed jaw.

- Place your workpiece between the jaws and tighten the clamp until it is secure.

- Use a bora clamp with other bora parallel clamps for larger projects, or use bora accessories such as the bora saw plate for added convenience and efficiency.

Experience the ease and security of bora parallel clamps on your next project. Your workpiece will thank you.

Final Words

Now that you know how to use woodworking parallel clamps, you're on your way to becoming a clamping pro! These versatile tools are excellent for various tasks, from holding pieces together while the glue dries to creating uniform pressure when sanding. Be sure to add a set of these necessary clamps to your shop today and see how they can help make all your future projects successful!