Sanding is a necessary step in any woodworking project, but it can also be the most tedious and time-consuming. This article provides you with tips for making sanding easier and faster than before! Some of these tips include: using a belt sander on larger surfaces, using an orbital sander when there are many smaller areas to sand, and always keeping your workstation clean. Read this blog post to find out more about these helpful hints.

Some people might think that the best way to get through sanding is by powering through it as quickly as possible; however, this approach often leads to mistakes that take even longer to correct. The following are some tips for avoiding common pitfalls while still getting your project finished on time:

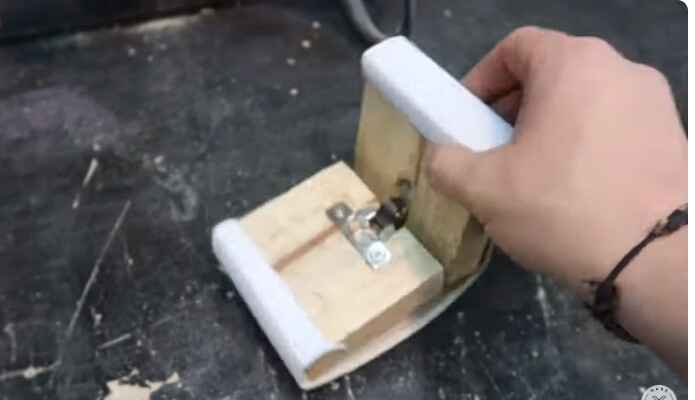

1. Easy to build drum sanding jig

Using the- easy to build, you can transform it from a power drill to a stationary edging sander. In which you can for an inner curving pattern. When you want to build like one, all you need is three/four-in. Scrap plywood, three/eight-in. Width 'U' shaped bolt to get fit around the drill and 2 three/eight-in. Winged nuts. Chuck lengths and house designing vary from drilling to drilling.

2. Clean Sandpaper through Using Your Old Sneaker

You can make your sanding paper fresh again like you just purchased it from the shop using your old sneaker. Turn on your sander and turn on your dust collector. Then gradually start pressing your rubber sole along the sanding paper.

3. Use Fabric Softener Sheet to Clean Eye Safety Glass

Clean your safety glasses by rubbing with a used fabric softener sheet. You will see more clearly while you are sanding.

4. Turn Your Shop-Vac into a Dust Collection System

Turn your shop-vac into a dust collection system. In this way, you do not have to out heaps of cash for a dust collector. Turn on the vacuum tube straightforwardly into the residue port of your apparatus. The size of residue ports on power hand devices differs. The best methodology for a 'DO IT YOURSELF' dust gatherer is to purchase an all-inclusive connector. You just cut the delicate elastic with a utility blade to fit the residue port on the instrument and the vacuum tube for a carpentry dust assortment framework.

5. Build Woodworking File for Sanding in Tight Spaces

Building a woodworking file can get useful for sanding in tight spaces. Slice a bit of sandpaper to fit around a paint mix stick. At that point, utilize splash cement or a universally handy paste to hold fast it to the rod. Compose the sandpaper coarseness on the handle of the mix stick, on the off chance that you intend to store it for some time in the future.

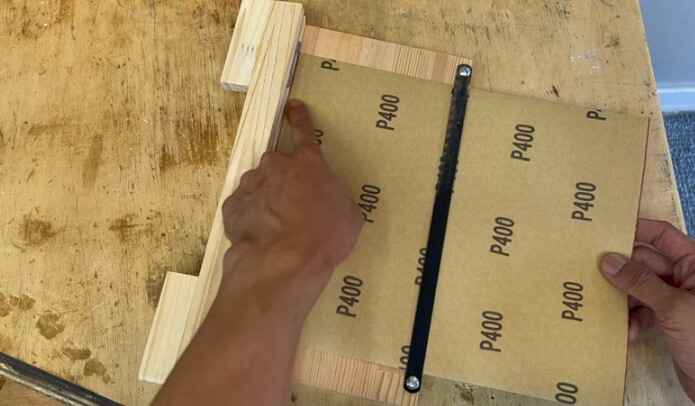

6. Build Sandpaper Cutting Jig for Your Finishing Sander

You can build a sandpaper cutting jig for your finishing sander. You can make it by turning your whole sanding paper sheet into small pieces. Cut that one/eight-in. Deep furrows in the base utilizing a slight kerf edge and a table saw, at that point, connect the stop square. If you want the jig to get used, you can put the sanding paper coarseness side down and run a sharp, capable blade down the suitable furrow.

7. Use Belt Sander to Sharpen Tools

If the bench sander is not with you, just use the belt sander to sharpen your tools with a fine sanding paper grit. To know more about knife sharpening, explore this article.

8. Use Swiffer Cloth for Sanding

Rub the work piece using a Swiffer cloth before you apply the finish. You are going to lift the polish and sanding dust sparkle the surface strands. Catch up with a Swiffer cloth to rub away any spots of residue or steel fleece.

9. Make your disposable sanding blocks out of scrap wood

Cut the blocks at three/four-in thick wood two and three/four inches wide by five and one/four inches long. You will need six blocks for each sanding paper and Spray adhesive both on the sanding paper and the chunks of wood. When it dries to the touch, lay the blocks on the paper leaving small gaps between them. You can write grits on the back of each block then cut the blocks. When you wear out a block, just peel the paper away and reuse the block. Make your disposable sanding blocks out of scrap wood.

10. Make Stationary Jigs to Hold Your Belt Sander to Work for a Tight Fit

The jig immovably holds your belt sander topsy turvy for more straightforward sanding of handheld venture parts. Every sander has an alternate shape, so uniquely cut the compressed wood sides with a jigsaw to accommodate yours. Always try working for a tight fit, so that the sander is rock consistent while working. Use cinches to hold little pieces and don't wear free attire.

11. Use a Radiator Hose for Contours

A hose sander is just another best tool for bent contours of the woodwork. Saw off a straight bit of disposed of radiator hose using a hacksaw, clear it all around, and wrap a bit of cement sponsored sandpaper on it. That works best when you hunker down on coarser sanding and is perfect for lighter-contact complete the process of sanding, as well.

12. Use Your Belt Sander as Typical Edge Sander

The belt sander clasped safely on its lateral makes an extraordinary sans hands sander to sand edges. Simply screw a three/four-inch, feed stage to a bigger one or two inches on plywood. You may likewise require a little one or four-inch. The compressed wood strip appeared to lift the sander body. Cinch the sander to the get-together. In case you're sanding a lot of pieces, you will need to include a bit of compressed wood sooner or later to the feed stage to even out the apparel of the sanding belt.

13. Dowel Scrub to Sand a Cove

When you want to sand a cove, get a dowel with a sweep that equals. If that you don't have self-cement sanding paper, simply squeeze the paper onto the dowel while working. Try not to create a dowel benefactor excessively lengthier. Slice it to the extent that is anything but difficult to deal with, and that uniforms the paper scope.

14. Use Duct Tape with Sandpaper for Sanding in Tight Spaces

Use a duct tape with sandpaper for sanding in tight spaces. The tape's extreme shroud lets you, Sand, without ripping the sanding paper. That strips work incredible for sanding machine turnings, washing, dried paste from venture parts and doing whatever other activity that requires a firm yet sensitive sanding contact. Utilize a sharp utility blade and a straightedge to cut those strips.

15. Reuse of dirty, sticky, or greasy Sanding Belts through Laundry Procedure

You can reuse the dirty, sticky, or greasy sanding belts through the laundry procedure. All you need to do is fill a pail with heated water and clothing cleanser, blend well, at that point hurl in the pitch-secured, and wore out belts. Let those drench for a few minutes, at that point scour off the relaxed flotsam, and jetsam with a firm bristled plastic brush. Put the belts in a safe spot, and when they are thoroughly dry, slice them into long strips for sanding squares or smaller pieces for unguided use on sensitive sanding employments. Oppose the compulsion to return the belts on your sanders; simply use those for hand-sanding.

16. Create a Platform for Edge Sanding

Create a platform for edge sanding easily. All you need to do is choose a plywood particle board and cut it to about twenty inches long and twelve inches wide spray adhesive both on the back of the sandpaper and the wood. When it dries to the touch, stick a sheet of each different get down onto the wood and mark the grid, so you don't get confused. When it wears out, just peel it off at a little more adhesive and replace it with a fresh sheet. Keep your sanding platform tucked away, and you will reach for it a lot more often than you might think.

17. Reuse of sanding sponge by wrapping them with grit sandpaper

You can start reusing the sanding sponge by wrapping them with any kind of grits sanding paper. You don't need to buy a new sanding paper for a long time.

18. A hardboard spline makes a great backer for reaching into grooves.

A hardboard spline makes a great backer for reaching into grooves. You need simple development, not a close-fitting slot. So its width is significant. For proficiency, press level against one side of the section, at that point, the other. At that point, tilt the sponsor against the arris on every side, thus to expel any wanderer filaments. A hardened board that is even on the two sides and one/eight-inch to three/sixteen inch thick creates an incredible benefactor for sanding one/four-inch- wide furrows.

19. Reuse Sanding Sponge by Writing the Grit Number on the Side of the Sanding Block

You can just write the grit number with a marker pen on the back of the sanding block and keep it in a shoebox. Later on, you can reuse those sanding sponges. Plus, you don't need to remember which of the blocks has which grits.

20. Folded Sanding Pad

You only need your hands and quarter sheets of sanding paper to fold the sanding pads. To progress the life span of this natural wonder, apply shower glue to the quarter sheets, at that point, fold those to style a twofold thick 1-8th sanding sheets.

21. Build Down Draft Sanding Box to Support Larger Work Pieces

If you want to build a downdraft sanding box, it is secure. It shallows the dust thoroughly. And it can enough support large work pieces sturdily.

22. Make Custom Sanding Bow and use them to shape and smooth furniture parts

You can use those custom made sanding bow, or you can call them shop-made wooden bows to smoothen the furniture by attaching it with some used belt strips. Those coarser grit can remove woods fast, and the finer grit will make the inclined surfaces shiny in no time.

23. Avoid Over Sanding

Force sand the highest points of compressed wood edges with ultra-lightweight, use fine-coarseness sanding paper and scrub a pencil solidly alongside the paste joint already sanding to help screen where, and how quickly, the surface is getting sanded. If that you press that sander extra towards the banding side, go moderate and keep an eye on the vanishing graphite. By this, you can avoid over sanding, and your plywood will also get saved from being wasted.

24. Cushioned Contour Sanding

The pad of the power sander is tad and too fixed if you want to polish seats. Sometimes it flats out some regions and doesn't create that cushioned soft contour which you want to get. So always keep an additional wad for your sander and make the smooth base by adding a bit of three/eight inches off-cells foam toward the end with some cement touch.

25. Custom-made Sanding Block to fit quarter sheets

If you want to keep your sandpaper fine without tearing on the borders two-one/two into five-inch custom made sanding block to fit quarter sheet, use glue on the of the coat of cap at the end of it.

26. Foam block a great backer for wet-sanding

The shut cell foam block got cut from a nursery stooping cushion. Flexible and waterproof, it's an incredible backer when wet-sanding.

Sanding in the layers of finish is essential to thump down residue nibs and equal any dribbles or different defects. Greasing up the paper, utilizing water for water-based completions, and inert spirits for dissolvable based items shields it from obstructing. Utilize a delicate, waterproof supporter wrapped with dry/wet silicon chemical paper.

27. Reuse Sanding Discs by Writing Grit Number on the Back

Reuse the sanding disc many times before they get torn out. Simply when you take a fresh pack of the drive, just label them by writing grits number on their back using a marker. By this, you can switch or change from grits to grits without outing pressure on your eyes.

28. Sand with the Grain

When you are using a power sander or if a hand sander always sands with the grain. Those scrapes are tight to see when the sander runs parallel towards the grains. Indeed, even the lightest scratches over the grain are self-evident, particularly in the wake of recoloring.

29. Making Belt Block

If you want to make a belt block, all you need to do is hook that belt two into four spread out to mark the distance.

Cut that two into four to an extent and pinch off the four corners at a forty-five-degree angle. Then try to fit the belt.

30. Pencil Visual Aid

Sanding the whole surface without missing a mess, level out difficult to-see high and low regions, and realize when to change to a better coarseness of sandpaper. The better the harshness, the lighter the pencil lines ought to be. It'll take a long time to Sand off dim lines with fine grit.

31. Hold Flashing Shield between the Sander and the Surface

The time you sand the border of the work piece, your power sander can dig some nasty dents or scrapes with the body of the sander and sanding paper on the contiguous surface. And that is not possible to get fixed. Hold a little sheet of metallic flash between the sander and cover where you don't want to get rung up. After that, without worrying, you can sand close as you wish.

32. Create Double Duty Drums to Support Huge Sanding

When you sand a whole lot of thin woods with your sander, it will mostly get wear out at the bottom of the drum sander. If you flip them over, will let you utilize the top, but the mid one stays unused. So cut that drum in half create double duty drum and flip those chunks to support heavy sanding.

33. Use a Scrap Piece of Carpet to Protect the Wood

Never scrape up your work when you just finished sanding by making it flip on a dinged table. Always use a scrap piece of carpet cushion when you sand to protect the wood. Hold the stationary as you go sanding and reduce the sander vibrations on your palm.

34. Know More about Belt Sanders for Effective and Safe Use

A belt sander is a sander utilized in forming and completing woods and different resources. It comprises of an electric engine that turns a couple of drums on which a constant circle of sandpaper gets mounted. The belt sander is one of the essential equipment in the world of sanding. This tool can save your time from getting wasted and smashup your work quickly. And to use safely always wear glasses, ear protection and surely a dust mask. Always turn off the tool and watch when it stops spinning.

35. Make Your Throwaway Blocks

Make your throwaway blocks. Paste-up a lot of expendable blocks and quit whining with reload locally acquired squares. At the point when the sandpaper's spent, hurl them and create more. A two into four feet. Bit of three/four inches. Medium-thickness fiberboard will make a ton of medium and fine blocks. Then start sawing that fiberboard into two-one/two x five-inches. At that point, space those blocks six on every sheet over sandpaper covered with splash cement. Using a thin utility blade, cut the sanding paper even with those blocks.

36. Use a Deck of Cards to Help Sand Contoured Edges

A deck of cards can make an incredible contour sanding hinder finished edges. Simply fold a bit of sandpaper over the long side of your bridge and handle the contradicting backs. Bear down the deck edges into your molded edge and start sanding.

37. Build Dustless Drilling and Drum Sanding with Your Shop Vac

Collect all the dust from the drum sanding before it gets into your mouth and then your lungs. You only need your shop vac, which is three into two in. Pin that magnet to the connection and put the connector over the end of the hose. A two-one/ fourth-in. Diameter. Shop vacuum hosepipe gets fitted cozily in the link's smaller end without cinches or adhesive. At that point, simply set the tube on the drilling press' metallic table and let that shop vacuum eat up all your residue.

38. PVC Sanding Files

Get the sanding paper with the cutoff slices of PVC pipe with spraying glue. PVC pipes get labeled by inner diameter. You can choose whichever you want to use it.

Smear sanding paper to the funnel, splash both the sandpaper and the channel with a liberal layer of glue. Let the two surfaces dry a few minutes before going along with them. Utilize two cornmeal on each channel-80-coarseness for chiseling an exact range, and 100/120-coarseness for complete the process of sanding. At the point when the sandpaper's exhausted, simply take it out, shower new cement on another strip, and return to having a great time.

39. Build Custom detail sander to Sand in the Tight Spaces

It is very tough to Sand tight spaces like shutters and louvered doors. The Rotating sander works the best. But when it comes to the sanding pad, you don't get it with the tool and is very costly. That is why it is advantageous to build your custom detail sander with a dull blade and traditional cut sanding paper with splashing glue to Sand in the tight spaces. When the sanding paper becomes useless, just peel off and put a new one.

40. Use chopstick, pencil, or skewer to Sand Curve

If the bend you have to sand is little, sliced the wipe to that extent. A bit of nursery hose or froth elastic will likewise work. If that bend is minor, secure the sandpaper with an elastic band around something exceptionally meager like a chopstick or a pencil.

41. Hand Sanding DIY

If you have some fantastic tools and some excellent sanding paper, you can smooth the wood using your hand with the best result. Sometimes It is better than using a power sander. "DO IT YOURSELF" hand-sanding is better sometimes than power tools.

42. Build PVC Dust Catcher with Your Shop Vac

Jolt a two-inch pot magnet to a four-inch into two-inch. PVC pipe reducer and place it close to the sander saw, switch, or machine that is making a residue storm in your shop. A two-inch shop vacuum hose 'fits' pleasantly in the two-inch reducer end, and the tub magnet fiercely holds any metal surface. Build a PVC dust catcher with your shop vac!

43. Make Your Incredible Sanding Block for Final Sanding

For the final sanding, it is hard to make up the timeworn hand sanding. At the point, when you set aside the force sanders and cautiously hand Sand with the grain, utilizing finer grit of sandpaper. You will create an even surface. Make your "great hand sander," stick a bit of a PC mouse cushion to a wooden sanding square. It makes a firm base that tenderly increments sanding twisting on flat exteriors. Utilize an overwhelming layer of photograph mount shower cement to stick the mouse cushion to the square. Apply cement sponsored sandpaper to the square for a start sanding steps. Since the finest sandpaper is not generally accessible with cement backing, apply conventional extra-fine to the square with a light layer of photograph mount splash. Make your incredible sanding block.

44. Keep your workshop dust-free by raising Your Shop Vacuum to Your Benchtop

If you are tired of saw dirt covering your woodworking tools and benchtop, then raise your shop vacuum to your benchtop, and it will keep your workshop dust-free.

The cognitive task will take you only a couple of hours to manufacture. Rip and slice to estimate any three/four-inch durable wood for the parts.

The riskiest piece of building this is slicing the lower part and fit into your vacuum. Cut the two into five inches section bits with a composite five-degree control and a ten-degree slope to match the bend of the container. A band saw will cut all these edges in a single pass. Test until the pieces fit close-fitting, and the higher board increases perpendicularly.

Defeat a three/four-inch full panel for the T-Track, focusing it on the T-Track board; base the T-Track with bolts; at that point, screw and paste on the calculated section pieces. Imprint and drill openings through the container and append the gathering with repairing plates and one-one/two-inch and number ten sheet metallic bolts.

Learn sanding tips and techniques in the video below

Final Words

Sanding is not easy work to do. But as we love our life and to where our life lives need to be beautiful and safe. Don’t forget to use safety. Make your life and home beautiful with these sanding tips and tricks.