Yes, you can use 18-gauge nails for baseboards. They are suitable for attaching baseboards to the wall. Ensure the length of the nails is appropriate for the thickness of the baseboard and the wall material.

Embarking on a DIY baseboard project and wondering if 18-gauge nails will make the cut? As a fellow DIY enthusiast who thrives on practical solutions, I delved into the world of baseboard installations to answer the burning question: Can I Use 18-Gauge Nails for Baseboard? Join me on this journey as we explore the ins and outs, sharing hands-on insights to help you make the right choice for your next home improvement venture. Let's hammer out the details together!

Yes, 18 gauge nails can be used for the baseboard. The thicker and longer the nail, the better it will hold your baseboard in place. However, depending on the material of your baseboard or trim work, other fasteners may be more suitable for securing them to the wall. If you are using wood as a material, 18 gauge nails should be sufficient unless you intend to adhere to heavier materials such as ceramic tile.

What gauge means in nails?

In nails, "gauge" refers to the thickness or diameter of the nail shank, usually expressed as a number. The lower the gauge number, the thicker the nail shank. For example, a 10-gauge nail is thicker than a 12-gauge nail.

The thickness of the nail shank affects its strength and holding power, with thicker nails being able to hold more weight or penetrate deeper into the wood. The appropriate gauge for a particular application depends on the type of wood, the weight the nail must hold, and the conditions it will be exposed to.

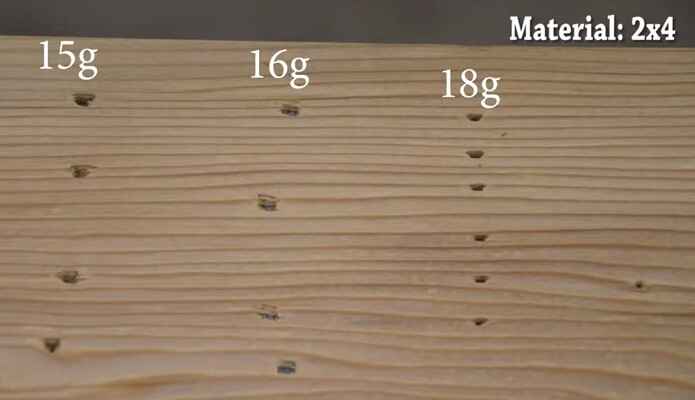

Different gauges nails and their uses

Nails come in a variety of sizes or gauges. Each size has its own purpose, from the smallest gauge to the largest. The thinnest nails are used for trim and lightweight molding, while the thickest can be used for framing construction. Intermediate-sized nails have many uses, including deck and siding building. Here's a closer look at the different gauges and their uses.

The smallest nails, known as finish nails, have a gauge of 18 to 23. They are great for attaching thin pieces of trim and lightweight molding. These small nails also hold well when used with a softwood like pine.

Next are brads, which have gauges from 16 up to 18. Brads can be used for the same applications as finish nails but will penetrate harder wood more efficiently.

Moving on to box nails, these gauge ranges from 14 to 16, providing enough strength for general carpentry projects. Box nails are ideal for constructing boxes, framing walls, and building decks and siding.

Finally, the thickest type of nail is a spike nail at 10-12 gauge. Spike nails are used for heavy construction projects like framing houses and other large structures.

No matter the job, there is a nail to fit the task. Finding the correct nail gauge can help ensure successful results in your next project.

Characteristics of 18 gauge nails

18 gauge nails are a popular choice for many carpentry and construction projects. They provide an ideal balance of affordability, strength, and corrosion resistance. Here are seven characteristics of 18 gauge nails:

Strength:

18 gauge nails offer a strong grip that is suitable for most applications. The shank diameter is small enough to fit into tight spaces while providing stability. Their robust construction makes them harder to bend or break than thinner gauges, making them well-suited for heavier materials such as hardwoods and engineered lumber.

Corrosion Resistance:

18 gauge nails are coated with specialized finishes that make them resistant to rusting and corrosion due to moisture exposure. This helps increase the lifespan of the nails, even when used in outdoor applications. The coating makes it easier to drive into the wood without splintering or damaging the material.

Affordability:

18 gauge nails are very cost-effective compared to other types of nails. This makes them ideal for projects where budget is a primary concern. In addition, because they are relatively small and lightweight, they are easy to store and transport in bulk quantities, making them an economical choice for larger projects as well.

Versatility:

18 gauge nails can be used in various applications thanks to their strength and corrosion resistance. They can be used indoors and outdoors on hardwood, particle boards, plywood, fiber cement boards, and more.

Durability:

18 gauge nails are designed to withstand heavy-duty use without breaking or bending. This makes them a great choice for projects where the nails will be subject to wear and tear over time, such as outdoor furniture or decking.

Accuracy:

The smaller size of 18 gauge nails helps ensure accurate placement when driving them into the wood. This is especially important when working with small materials and tight joints, making 18 gauge nails an excellent choice for precision work.

Easy To Install:

Thanks to their smaller size and specialized coatings, 18 gauge nails are easy to install with minimal effort. They can be driven into wood quickly and accurately with most tools, including brad nailers, hammers, and nail guns. This makes them ideal for projects that require speed and efficiency.

Pros and cons of using 18 gauge nails for baseboard

Installing a baseboard is an essential part of any home renovation project. While the type of nail used could seem like a minor detail, selecting the wrong gauge can make all the difference. Here are some pros and cons of using 18 gauge nails for your baseboard installation.

Pros:

1: Easy to Use

18 gauge nails are relatively thin, making them easy to drive into place with minimal effort. Furthermore, they don't require a heavy-duty hammer or special tools, meaning most homeowners can handle the task independently.

2: Aesthetically Pleasing

The small size of 18 gauge nails allows them to blend in seamlessly with the baseboard material and paint, giving your project an understated, polished look. This is especially true for those who avoid "over-nailing" their baseboard installation.

3: Cost Effective

18 gauge nails are one of the most affordable nail options, making it easy to stay within budget when installing a new baseboard. They are also widely available from home improvement stores and online retailers.

Cons:

1: Limited Holding Power

Due to their small size, 18 gauge nails offer limited holding power. This means they may not be suitable for large baseboard projects or additional support.

2: Easily Bent

18 gauge nails are more likely to bend when driven into place than thicker-gauge nails. If bent too far, the nail can be rendered unusable, thus adding time and cost to your project.

3: Unsuitable for Certain Materials

Some materials - such as hardwood - may require a thicker nail for adequate hold. As such, checking the manufacturer's guidelines before using 18 gauge nails on any particular material is essential.

18 gauge nails can be a great option for smaller, lighter baseboard projects. However, they may not provide the necessary support and hold needed for larger installations. It's essential to research before making any decisions and ensure you select the right gauge nail for your project.

Factors to consider when choosing nails for baseboard

Getting the right nail for your baseboard can make all the difference. Here are six factors to consider:

1. Nail Size & Length

Before selecting a nail, measure the thickness of the baseboard and select nails accordingly. Nails should be long enough to penetrate past the backside of wall studs or furring strips into solid wood framing for a secure fit.

2. Durability

Choose an appropriate material for your nails based on environmental conditions and how much wear and tear they must withstand. Common materials used for nails include steel, stainless steel, aluminum, brass, and copper. Some materials are better suited depending on the application, such as exterior projects requiring more corrosion-resistant special alloy nails.

3. Collation

This is the method by which the nails are attached. Common collation methods used for nails include paper, plastic, wire, and glue. Each has its benefits and drawbacks, depending on the project. For instance, paper-collated nails are less likely to jam in the gun but more likely to bend during application.

4. Finish

The type of finish on your nails can affect your project's look and how long the nails will last. Standard finishes used for nails include galvanized, coated, and uncoated. Consider the environment in which the project will be located when choosing a finish and any special needs such as corrosion resistance.

5. Point

The point of the nail affects its ability to penetrate a material. Common nail points include diamonds, spirals, and chisel. Diamond points are for general applications, while spiral and chisel points are better suited for harder materials such as concrete or stucco.

6. Compatibility

Select nails compatible with your tools and fastening equipment, such as pneumatic guns or manual hammers. Selecting incompatible nails can cause issues when driving them into place or damage your tools.

With these six factors in mind, you can be sure to find the right type of nail for your baseboard project!

Final Words

While it is possible to use 18 gauge nails for baseboards, we recommend using 16 or even 14 gauge nails. The thicker the nail, the less likely it is to bend or break. And when dealing with something as important as your home's baseboards, you want to ensure you're using the best materials possible. With a little research and care, you can ensure your next home improvement project succeeds.