In the world of DIY projects, woodworking, and home renovations, there exists a humble yet indispensable tool that often goes unnoticed—the sandpaper. But, did you know that this seemingly simple abrasive sheet comes in a multitude of grits, each with its own unique superpower?

Prepare to be amazed as we embark on a journey through the fascinating world of sandpaper, unveiling 31 diverse applications that will revolutionize the way you approach tasks around the house, in the workshop, or on your creative endeavors.

From polishing to precision, from restoration to refinement, sandpaper grits hold the key to unlocking unprecedented efficiency in your projects. So, let's dive in and discover the true potential of this unsung hero!

The finest sandpaper grit is 280-320, are the completing geniuses. Working with these papers close by, it is anything but complicated to get the charming, plush completion you want.

The finest sandpaper grit is 280-320, are the completing geniuses. Working with these papers close by, it is anything but complicated to get the charming, plush completion you want.

The fine grit papers are super helpful with the application of a layer of clear coat. They will totally level out any peaks left by the coarser papers, leaving you with an amazing still wet surface that will enable you to have the most astounding paint end conceivable.

Additionally, these papers are perfect for removing any undesirable surface scratches. In the event that you have a scratch on the vehicle that you're working on, you can use this sandpaper to level it out and clear paint over it.

What is Medium Grit Sandpaper?

Medium sandpaper, extending from sixty to one hundred grit, suits some last molding. Necessary sanding of unpleasant wood and the evacuation of arranging blemishes on wood is regularly best finished with medium sandpaper grit.

Sandpaper has a variety of different sizes and levels of coarseness. Medium grit sandpaper falls in between fine and coarse sandpapers.

Medium grit can be used for items such as refinishing furniture, painting pieces, removing drywall or tile paint, and removing stickers from glass jars. It can also be helpful when you're working on something that is fairly large like a wood table or floor boards.

The two things that make medium grade sandpaper stand out from other grades are the fact that it isn't as rough against the surface of what you're working on and secondly the medium grade actually absorbs less material than finer grades because it doesn't do an optimal job with smoothing wood surfaces but still does a great job with

What is the Lowest Grit Sandpaper?

The smallest sandpaper grit sizes run from forty to sixty. This ultra-coarse paper is perfect for large, profound sanding ventures with a ton of surface unpleasantness.

Coarse sandpaper is used for the preliminary stages of a sanding venture, particularly where there are innumerable dents and nicks in the wood. It can likewise be utilized to strip off old paint or guarantee that all forms of buildup have been totally eliminated. Coarse sandpaper can make it simple to trim away paints without disturbing the timber grain of your wood.

Coarse sandpaper can likewise be utilized to resurface floors, and even concrete! This is an incredible approach to mix things up a bit and use your coarse sand paper in regions that you might not at first consider possible. You need just as much material for this type of venture, however the outcomes are totally fascinating!

What Grit Sandpaper to Use (31 Applications)

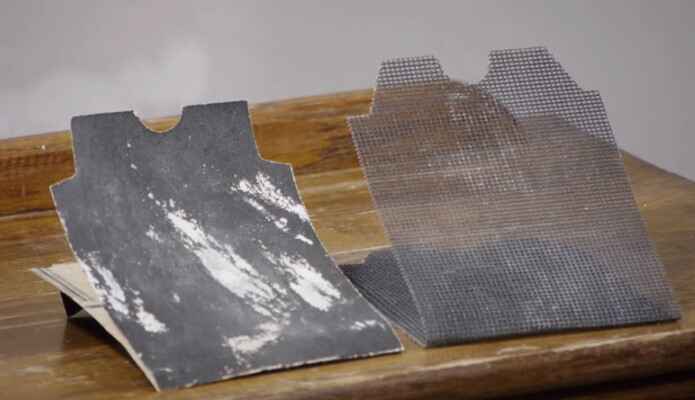

1. What Grit Sandpaper for Drywall?

When sanding drywall, it's common to use a variety of grits of sandpaper to achieve a smooth and even finish. The specific grit you start with and progress to depends on the stage of the drywall finishing process. Here are some guidelines for choosing the right grit sandpaper for drywall:

Coarse Grit (60-100):

Use coarse-grit sandpaper (around 60 to 100 grit) for the initial sanding of drywall joints and seams after applying joint compound. This coarse grit helps remove excess compound and level out any uneven spots or ridges.

Medium Grit (120-150):

After the initial sanding, switch to medium-grit sandpaper (around 120 to 150 grit) for the second sanding pass. This step is crucial for smoothing out the surface and feathering the edges of the joint compound. It helps blend the joints and create a more seamless look.

Fine Grit (180-220):

For the final sanding before painting, use fine-grit sandpaper (around 180 to 220 grit). This step is essential for achieving a smooth and blemish-free finish. It helps remove any remaining imperfections, dust, and creates a surface that's ready for paint or wallpaper.

Very Fine Grit (320-400):

In some cases, especially when you're going for an exceptionally smooth finish, you can use very fine-grit sandpaper (around 320 to 400 grit) for an additional pass. This step further refines the surface, ensuring a professional result.

Health Tip:

Remember to wear appropriate safety gear, such as a dust mask and safety goggles, when sanding drywall to protect yourself from dust and debris.

2. What Grit Sandpaper for Wood?

The choice of grit sandpaper for wood depends on the task you're performing and the desired level of finish. Different grits are used for different purposes in woodworking. Here's a general guideline:

Coarse Grits (40-80):

These grits are used for heavy material removal and shaping. You might use them when you need to remove a lot of material quickly, such as when roughing out a project or sanding down rough, uneven surfaces.

Medium Grits (100-150):

This range of grits is suitable for general sanding and smoothing of wood surfaces. You would use medium grits for tasks like refining shapes and removing the scratches left by coarser grits.

Fine Grits (180-220):

Fine grits are used for finishing and preparing wood for staining or finishing. They are good for removing fine scratches, leveling surfaces, and achieving a smooth finish.

Very Fine Grits (320-400+):

These grits are used for final sanding before applying a finish like paint, varnish, or stain. They create a very smooth surface and help ensure an even finish.

Here are some specific scenarios to help you choose the appropriate grit:

- Initial Sanding: Start with a coarse grit (e.g., 80) to remove any rough surfaces, and then work your way up to finer grits for smoother results.

- Between Coats of Finish: When applying multiple coats of finish, use a fine or very fine grit (e.g., 220-400) to lightly sand between coats. This helps create a smooth, even finish.

- Wood Preparation for Painting or Staining: A medium to fine grit (e.g., 150-220) is often suitable for preparing the wood surface before applying paint or stain.

- Detail Work: For detailed or delicate work, you may need to use very fine grits (e.g., 400+) to avoid over-sanding or damaging small features.

Important Note:

Keep in mind that the type of wood you're working with and the specific project requirements can also influence your choice of sandpaper grit. It's a good practice to start with a coarser grit and progressively move to finer grits for the best results. Always follow the wood grain and change sandpaper when it becomes clogged or worn to maintain efficiency and avoid leaving unwanted scratches on your woodwork.

3. What Grit Sandpaper for Deck?

The grit of sandpaper you should use for sanding a deck depends on the specific task you're trying to accomplish. Generally, for refinishing or preparing a wooden deck, you'll want to use a range of sandpaper grits to achieve the best results. Here's a guideline:

Coarse Grit (40-60):

Start with a coarse-grit sandpaper (40 to 60 grit) to remove any old paint, stubborn stains, or rough spots on the deck surface. This grit is effective for heavy material removal and should be used sparingly to avoid over-sanding the wood.

Medium Grit (80-120):

After using the coarse grit, move on to a medium-grit sandpaper (80 to 120 grit). This will help to smooth out the surface, remove scratches left by the coarse grit, and prepare the wood for refinishing.

Fine Grit (150-220):

Finish the sanding process with a fine-grit sandpaper (150 to 220 grit). This will further smooth the wood surface and prepare it for staining or sealing. It's also suitable for removing any remaining marks from the medium-grit sanding.

Extra Fine Grit (220+):

If you want an exceptionally smooth finish on your deck, you can use an extra fine-grit sandpaper with a grit rating higher than 220. This step is optional and can provide a polished look, but it's not always necessary for a functional deck.

Pro Tip:

Before you start sanding your deck, assess its condition and the type of finish you want to apply. The choice of sandpaper grit can vary depending on factors such as the wood's condition, the type of stain or sealer you plan to use, and your desired level of smoothness.

4. What Grit Sandpaper for Wood Floors?

The choice of grit sandpaper for wood floors depends on the specific stage of refinishing or the condition of the wood surface. Here's a general guideline for choosing the appropriate grit sandpaper:

Coarse Grit (20-36):

Use coarse grit sandpaper to remove old finish, deep scratches, or gouges from the wood surface. It's also suitable for leveling uneven areas or addressing significant imperfections. Start with a lower grit and gradually move to finer grits for a smoother finish.

Medium Grit (40-80):

Medium grit sandpaper is used to further smooth the surface after using coarse grit sandpaper. It helps to eliminate the scratches left by the coarser paper and prepare the wood for finer sanding. This is a crucial step in the refinishing process.

Fine Grit (100-150):

Fine-grit sandpaper is typically used for the final sanding before applying a finish. It helps to remove the marks left by medium grit sandpaper and provides a smooth and even surface for finishing. It's essential for achieving a professional-looking result.

Very Fine Grit (180-220):

Very fine grit sandpaper is used for finishing touches, especially when you want an exceptionally smooth and polished surface. It's often used before applying the final coat of finish to a hardwood floor.

Extra Fine Grit (240 and above):

Extra fine grit sandpaper is used for ultra-smooth finishes and between-coat sanding when applying multiple coats of finish. It helps to ensure a flawless final appearance.

Pro Tip:

When sanding wood floors, it's common to start with a lower grit and progressively work your way up to finer grits. For example, you might start with a coarse grit like 20 or 36 to remove old finish and imperfections, then move to medium grits like 40 to 80 for smoothing, followed by fine grits like 100 to 150 for final sanding. Always follow the manufacturer's recommendations for the specific sandpaper you are using. Clean the surface thoroughly between grit changes to avoid cross-contamination and achieve the best results.

5. What grit sandpaper for car?

Even though you can utilize 300 - 400 Sandpaper grit or higher for a car, if you are wet sanding, you ought to most likely use 1,000 - 2,000 sanding grit to accomplish the best outcomes. Make sure to keep the paper moist during the whole procedure of sanding, and never permit the sanding paper to get dry.

The most fundamental method to wet sand a car is by utilizing an orbital sander. If you are using this device, be certain that you have actually turned off the pelt level on your machine and tuned up the level of water in your pad. If it feels like there is too much water in the pad when it comes into contact with the surface, you could have to adjust it a little bit. You will see this on your pad after a while, and if you cannot get it level with water, then take the sander to an expert for further assistance.

Another way that you can do wet sanding is by utilizing the palm of my hand as my tool. This will allow me to have additional control over the sanding procedure, and could be performed using very little water. If you are utilizing this approach, it is a good idea to utilize a paint strainer bag that can catch all of the particles and keep them from going into your sander. This method too is slower than an orbital sander or a rotary sander, but can provide you with more control over the outcome.

As far as making a decision what grit sand paper to utilize goes, that will be determined by if you are updating the finish or just touching it up. If your paint is entirely worn off and all you intend on doing is touching it up to get rid of some surface rust, then you can utilize an ultra-fine sandpaper. In case you are repainting a finish or doing anything where there is paint on the automobile that needs to be taken off, you ought to use at least 1,000 grit if not 2,000.

6. What Grit Sandpaper for Headlights?

When you are using grits for headlights that are vigorously oxidized and overcast, it's acceptable, to begin with, 400 sandpaper grit. If lights aren't excessively shady, at that point, you can utilize 600 sandpaper grit. Before you start sanding, apply water on the headlights and the sanding paper.

Moving toward the end, make utilization of 800 sandpaper grit. In the wake of completing the entire procedure you can use 1000-1500 grit sand paper to wash off all the soil and left over particles. Finally utilize a polish wrap up sandpapers for smoothening out your headlights and additionally to stay away from oxidization.

Do not utilize 1000-1500 grit sandpaper on haggle headlamps. It will bring about general damage to the headlights. In the event that you need to clean up your dark headlights, at that point make utilization of compound or tape wrap up papers in 600 and 800 girt sizes. Utilize rubbing compound for light clouded headlights. Utilize compound with a high gloss shine for moderately clouded and dull headlights.

7. What Grit Sandpaper for Metal?

The sandpaper promptly scrapes metal, and that scratch marks aren't as simple to expel comparing to wood. When you sand metal to expel the deburr an edge or rust, in this manner, you shouldn't utilize grit sandpaper with a coarser than 220. If conceivable, you can use a much better one, for example, 320.

Grit sandpaper can likewise be utilized on smooth metal surfaces to separate rust or by getting rid of undesirable layers. Sandpapers with coarser grits have a tendency to leave uneven scratch marks that may require some smoothing out with another material, for example, a sponge or another piece of metal.

Pre-cut sandpapers are generally not endorsed for metal, since the sandpaper can't stick to the surface and may get caught in the moving parts of a machine. In this way, it is best to utilize a belt sander or an abrasive sheet attachment that you could use with a power drill. A great alternative is an auto deburr attachment. This attachment works better with smaller parts of metal, particularly those that need to be spot-sanded.

The size of the sandpaper is important in sanding metal. Sandpapers are generally sold based on its thickness and length or width. The measurements are expressed in inches rather than millimeters with a few exception for extra large sheets such as 12" x 48". The thickness is typically measured in eighths of an inch.

The length or width is expressed in feet and inches for auto sandpapers, while the sheets sold at home improvement stores are generally half a foot longer than they are wide. Metalworkers will also set up their own custom-made sandpaper sheets that have different sizes and lengths if they need to finish a project.

8. What Grit Sandpaper for Spackle?

Typical spackling glue fixes, by and large, require medium sandpaper grit for spackle. Medium sandpaper grit goes from roughly 80- 120 sandpaper grit. Notwithstanding, heavier or lighter sandpaper grits may apply to exceptional spackling conditions. Before choosing the sandpaper grit for spackle, you should read details about sanding spackle.

9. What Grit Sandpaper for Wet Sanding Clear Coat?

The clear coat ought to be wet sanded with 400 sanding paper grit. It is to supplant the orangy strip with a more excellent scratch, which will, in the long run, filled in with clean. This sanding steps help lessen the clear coat until the whole surface is even.

10. What Grit Sandpaper to Remove Paint from Wood?

Different colors of paint require different grit sandpaper. So the critical thing that needs to be known is what color your existing painted surface is before you can effectively determine what grit sandpaper would best suit your need.

The following chart will give you a quick reference on what Grit Sandpaper to use to achieve the desired surface appearance:

80-grit - Rough surfaces such as bare wood, drywall compound, rust, dried putty, and light crayon markings on non-painted wallboard or plaster. Removing paint, smoothing wood.

60-grit - Smooth down raised grain, clean up very rough surfaces, moderate to major paint removal. Remove old wallboard compound.

40-grit - More serious paint removals and heavy rust removal (not galvanized). Toothpaste marks on painted walls. Sand through any existing texture coatings (orange peel effect) without raising the grain. Remove but not replace wallpaper border designs. Moderate sanding of hardwood floors between finish coats or stain coats; removes marks left by 80-or 120-grit sanding (light color woods only).

Finish With 100 Grit - Lightly sand for a smooth surface before applying final coatings of paint or varnish; leaves no scratches.

120-grit - Remove all previous sanding scratches. Minor paint removal or general smoothing of wood surfaces.

180-grit - Removes heavy to moderate amounts of paint and light rust from steel (galvanized) surfaces. Smooth rough concrete before applying epoxy coatings when dusting, brushing, or pressure is insufficient to clean the surface sufficiently. Scratch out small depressions in concrete when an extremely smooth finish is desired. Heavy scratches can be removed by quickly applying 150-or 220-grit paper before the final smoothing with 180 grit. Sandpapers up to 320 grit can be used to prepare a painted or varnished floor just before recoating for minor defects and blemishes previously removed with 60-or 80-grit sandpaper.

320-grit - Final preparation of a painted or varnished floor just before recoating for minor defects and blemishes previously removed with 60-or 80-grit sandpaper. Excellent initial surface appearance on all types of stone, slate, marble, metal, and wood.

400 Grit – Hand finishing work on natural stones such as marble to a fine luster before sealing or polishing; very popular in Europe. Also used as an intermediate stage between 120 and 180 grit for removing rust from steel surfaces (not galvanized). Pre-finish hardwood floors for paint or oil finishes by hand rubbing with 400 grit paper followed by 800 grit until desired surface smoothness is achieved.

600-grit - General purpose sanding of bare wood, minor smoothing of slightly rough surfaces before painting or varnishing. Removes saw marks and nail chips from raw wood; slight rust removal from unpainted metal surfaces (copper, brass, aluminum); remove burrs and sharp edges from all metals.

800-grit - Smooth surfaces such as bare wood gloss the surface of the varnished floor before buffing with a polishing compound, remove black streaks from unpainted metal, general purpose sanding for smoothness and shine on many surfaces.

1000-grit - Refinish a varnished floor or clean up a previous stage in major floor refinishing, final preparation for paint removal from any surface other than galvanized steel.

11. What Grit Sandpaper To Remove Clear Coat?

My recommendation would be 60 or 80 grit sandpaper. Begin with the sandpaper of 100grit, which is usually coarser. However, if you sand for a long period, it causes the clear coat to melt and flow onto the paint layer below. So immediately move to either 40 or 80 grit paper until all traces of clear coat are gone.

It's important not to use too much pressure because this will remove some paint and a non-worn clear coat. The final step is to go over an area with lower grit sandpaper to confirm that all the old clear coat has been removed. However, this will require more physical effort than before since there is less surface contact between high and low grit paper due to the reduced thickness of the clear coat.

Three areas need to be sanded. First, you'll have to sand the scratches out using 60 grit paper with slight pressure on an angle that is not 45 degrees or 90 degrees but somewhere between these two angles. Then use 40grit paper and sand perpendicularly until both layers of scratches are removed.

And finally, use 100grit sandpaper to ensure that the scratches are gone and then go over it with your hand, ensuring that there aren't any scratch marks left behind.

The second important thing is not to sand on a very humid or rainy day because chances are you'll be removing some of the paint in addition to the clear coat, and this will eventually lead to permanent damage in addition to a reduced resale value. Also, wear goggles and gloves using rubber sheets on your arms so that no part of your body touches the car. If you do so, there's a high possibility that you'll get scratches or even injure yourself, which would be very unfortunate.

12. What Grit Sandpaper for Plastic?

Since plastic scrapes effectively, coarse sanding paper grit isn't suggested. The best technique is to start wet sanding with 220 sandpaper grit and make extra goes with dynamically better paper until you're content with the entrance.

13. What Grit Sandpaper for Cabinets?

Sand the cabinets utilizing a power sander and 100 grit sandpaper for the underlying sanding—sand notches and corners with sandpaper. Wrap up by sanding with 150 sandpaper grit or by hand, sanding lengthways the grain of the wooden surface. Wipe off the residue.

14. What Grit Sandpaper for Concrete Floors?

Use coarser grit sandpaper in the range of forty to sixty grits range for necessary sanding. For removing slight inadequacy, use 80 to 120 grit sanding paper. If you want a smooth finish use the finest sanding sand-like 200- 400 or more than that.

15. What Grit Sandpaper for Polyurethane?

The choice of grit sandpaper for polyurethane depends on the stage of the finishing process you're in and your desired outcome. Here are some general guidelines:

Preparation and Between Coats:

When applying polyurethane in multiple coats, it's common to sand between coats to create a smooth and even surface. For this purpose, use a fine-grit sandpaper, typically in the range of 220 to 400 grit. This helps remove imperfections, such as dust particles or brush marks, and provides a good surface for the next coat to adhere to.

Final Finish:

If you're looking to achieve a super smooth and glossy finish, you can use an even finer grit sandpaper, such as 400 to 600 grit, for a final sanding. This will help remove any remaining imperfections and create a glass-like finish.

Repairing Imperfections:

If you encounter drips, runs, or other imperfections in the dried polyurethane, you may need to use a coarser grit sandpaper, like 150 to 180 grit, to carefully remove the imperfections. Afterward, you can progressively move to finer grits for blending and smoothing.

Health Tip:

be cautious when sanding polyurethane, as it can generate fine dust that can be harmful if inhaled. Use proper safety precautions, such as wearing a dust mask and eye protection, and work in a well-ventilated area.

16. What Grit Sandpaper for Glass?

The choice of grit sandpaper for glass depends on the specific task you're trying to accomplish. Here are some common grit recommendations for different glass sanding tasks:

Removing Scratches or Blemishes:

If you're trying to remove scratches or blemishes from glass, start with a higher grit sandpaper, such as 400 to 600 grit. This finer grit will help smooth out the surface without causing deep abrasions.

Prepping for Painting or Coating:

If you need to prepare the glass surface for painting or applying a coating, you can start with a 220 to 320 grit sandpaper. This will provide enough texture for the paint or coating to adhere to.

Edge Smoothing:

When you're working on the edges of glass, like when you're finishing cut edges or rounding corners, you can use 400 to 600 grit sandpaper. This will help smooth the edges without causing chipping.

Glass Restoration:

For more significant glass restoration or heavy-duty tasks, you might need to start with a coarser grit, like 100 to 220, to remove deeper scratches and then gradually move to finer grits to restore the glass to a smooth, clear finish.

Polishing:

If your goal is to achieve a high-gloss, polished finish on glass, you'll want to use very fine grit sandpaper, typically 800 to 2000 grit or higher. Additionally, you can use polishing compounds or cerium oxide with a buffing wheel to achieve a pristine shine.

It's a good practice to start with a finer grit and work your way up to coarser grits if necessary, depending on the severity of imperfections you're trying to address. Additionally, be sure to wear appropriate safety gear, including eye protection and a dust mask, when working with sandpaper and glass.

Pro Tip:

Always keep in mind that when sanding glass, it's important to be gentle and patient. Glass is a fragile material, and excessive pressure or using too coarse a grit can cause further damage. Use water or a glass lubricant while sanding to reduce friction and prevent heat buildup, which can also lead to cracking or damage.

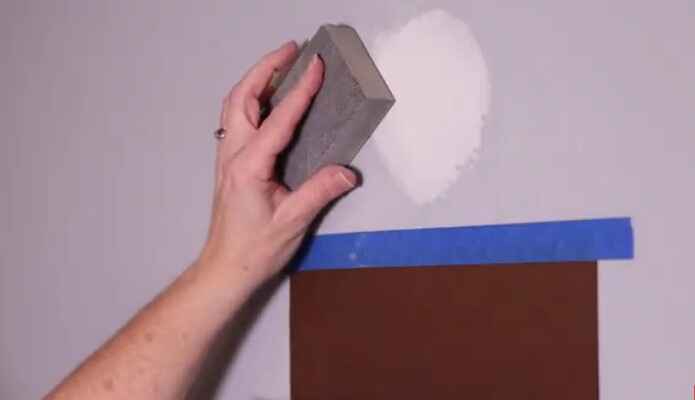

17. What Grit Sandpaper for Joint Compound?

You will need to use 100-120 grits once the joint compound is dry. Then use 150-220 t sanding screen, or you can use sanding sponge smoothen the joint compound.

18. What Grit Sandpaper for Bondo?

At first, use a grater; after that, use 40 grit and then 80 for Bondo. Later on, put polyester putty and then again go for 180 and then 220 or 320. Utilize a filling primer that gets sanded within 400/600 just before coloring.

19. What Grit Sandpaper for Refinishing Hardwood Floors?

Utilize 24, 40, 80 and 120 grits sanding paper for refinishing a hardwood floor. At first, sand using some.

The coarse sanding paper (24 grit). After evacuating the vast majority of the stain and old varnish, you can proceed onward the less rough sanding paper.

20. What Grit Sandpaper to Remove Varnish from Wood?

At first, sand off the old varnish with 150 grits sanding paper to remove varnish from the wooden surface. After you expel as much as could be expected under the circumstances, go for 220 grit sanding paper until the entirety of the varnish is no more.

21. What Grit Sandpaper for Walls?

120/150 grits sanding paper is best for the walls, and while sanding, use light-sensible pressure. If your wall has holes or scrapes, it is best to fill them before sanding.

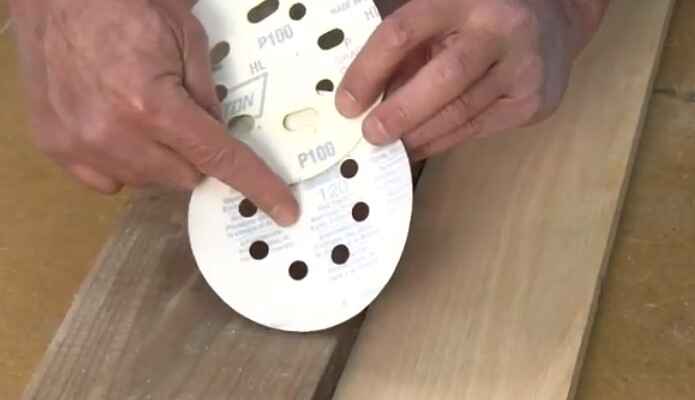

22. What Grit Sandpaper for Wet Sanding?

For wet sanding, you can use up to 3000 grits sanding paper. But most people are satisfied with 1500-2000. Ensure that you use the water in sandpaper, which gets made for wet sanding works.

23. What Grit Sandpaper for Sheetrock?

Use 100/120 grits of sandpaper for sheetrock. You can use 150/220 grits sanding screen to smoothen the joint compound. When you are sanding sand properly and watch out if you gets blend with the other walls.

24. What Grit Sandpaper for Knife Sharpening?

Using 220 grits of sandpaper can sharpen your knife very nicely and remove a lot of residues. If your knife is very dull, use 1000/1500 grit.

25. What Grit Sandpaper for Paint Prep?

Finer grits of sandpaper-like 180-220 are best to remove the scrapes that got left by coarse grits on a wood that did not finish and also for gently sanding in between layers of paint.

26. What grit sandpaper for drywall mud?

You can use 100/120 grits sanding paper for drywall mud. Use 150/220 sanding screen or fine sanding squeegee to smoothen it.

27. What grit sandpaper for paint?

Before you paint the walls, gently coarsen the area with a medium grit sanding paper like 120. If you don't need to brush and only need to restain, then first go for 120 and the 180.

28. What grit sandpaper for primer?

There are many grit sandpaper for primers, but the best one-grit sandpaper is 100. Your projects have a smoother finish and the risks of stripping paint from surfaces or damaging wood panels is minimized with it.

So what does this mean? It means that even if you only have $5 in your wallet to buy sandpaper, it's definitely worth getting some use out of those 5 dollars by buying 100 grit instead of 80 like most people would do.

This might all sound confusing or complicated; and in a way you're right because at first glance, there doesn't seem to be much difference between various grade sandpapers. However long story short? The higher the number typically means that the surface has finer scratches or grooves.

It means that the higher the grit number, the more it's rough in appearance and texture but has a smoother finish.

You see sandpaper with finer scratches or grooves are able to hold on to paint better because there is more surface area for paint to attach itself. What this means is that you get a smooth finish using 100 instead of 80 even if you're not doing any of those fancy techniques like applying multiple thin coats or brushing light coats (both methods require a perfect finish). This doesn't mean that 80 isn't good enough; however it does mean that what we want when painting something is a finish as smooth and polished as possible without having to spend lots of time getting rid of brush marks by hand. What we want is to apply paint and have it stick on the surface as quickly as possible without having to go over the same area numerous times. What we want is for paint to be applied easily while getting a smooth finish; all of which 100 grit sandpaper can do just fine.

29. What grit sandpaper for exterior house?

The 50 grits sanding paper is the most usual grit that gets used on the exterior of the house with minimum outward composition. But the sanding paper grits are recognized within the number. The lowest number is the roughest, and if you have a surface with a lot of pf coats of paint, you can go for 36 grits.

30. What grit sandpaper for epoxy?

Epoxy is challenging to sand because of its extreme hardness. At first, use 60 to 80 grits sanding paper and then 180-220 or 320 for the final the sanding preceding to varnishing or priming.

31. What grit sandpaper for wood filler?

You can start with 180- 220 grits sanding paper and the next with 180-220 for wood filler.

Find out what kind of sandpaper grit you should use by watching this video.

Final Words

Sandpaper does not get made with sand, obviously, but instead, it comprises of fine particles from either characteristic or engineered sources. Those elements are filtered finished screens and arranged by size before getting reinforced with glue with the paper, wipe, or fabric type sponsorship to make a grating substantial that is helpful in various doing it without anyone else's help circumstances.