To adjust the cut-out pressure on an air compressor, locate the pressure switch. Turn the adjusting nut clockwise to increase and counterclockwise to decrease pressure. Use a pressure gauge to verify settings for optimal performance.

Curious about optimizing your air compressor's performance? Understanding and adjusting the cut-out pressure is a key skill for beginners. In this guide, we demystify the process, providing simple steps to ensure your air compressor operates at its best. Say goodbye to guesswork and hello to a smoother, more efficient pneumatic experience. Let's dive straight into the basics of adjusting cut-out pressure – it's easier than you think!

What is the cut out pressure on an air compressor and why is it important to adjust it correctly

As with any mechanical device, an air compressor has several key performance indicators that must be monitored to ensure optimal operation. One of these is the cut-out pressure, the point at which the compressor will automatically shut off.

If the cut-out pressure is too low, the compressor will cycle on and off too frequently, leading to premature wear and tear. Conversely, if it is set too high, the compressor will run for longer periods than necessary, resulting in wasted energy and increased operating costs.

The cut-out pressure is typically adjusted through a pressure switch, which is a simple mechanical device that activates or deactivates the compressor based on the pressure in the system. Pressure switches are typically adjustable, which allows the cut-out pressure to be fine-tuned to the specific application.

It is important to note that the cut-out pressure is not the same as the maximum operating pressure of the compressor. The latter is a safety feature that prevents the compressor from being damaged by excessively high pressure.

The cut-out pressure should be set according to the application's specific needs. In general, it is advisable to err on the side of caution and set the cut-out pressure slightly below the maximum operating pressure of the compressor. This will help avoid any potential damage to the unit and minimize the risk of premature wear and tear.

How to find the cut out pressure on your compressor?

When operating a compressor, one of the most important things to keep in mind is the cut out pressure. This is the pressure at which the compressor will stop running. If the cut out pressure is too low, the compressor will constantly cycle on and off, which can shorten its lifespan. On the other hand, if the cut out pressure is too high, the compressor will never turn on, which can also cause problems.

The best way to find the compressor's cut-out pressure is to consult the owner's manual. This will give you the specific pressure for your model of compressor. You can also find this information online on the manufacturer's website.

If you can't find the cut out pressure in the owner's manual or online, you can try contacting the manufacturer directly. They should be able to give you this information.

Once you know the cut out pressure for your compressor, you can adjust it as needed. If the cut out pressure is too low, you can increase it by turning the knob or screw that controls it. If the cut out pressure is too high, you can decrease it by turning the knob or screw in the opposite direction.

Adjusting the cut out pressure is a simple way to keep your compressor running smoothly. By doing this, you can extend its lifespan and avoid any unnecessary repairs.

How to adjust cut out pressure on air compressor?

If you're like most people, you probably don't think much about the cut out pressure on your compressor. But if you're a professional air compressor user, it's important to know how to adjust the pressure. Here's a step-by-step guide on how to do it.

1. Check the manufacturer's specifications.

The first thing you need to do is check the manufacturer's specifications for your specific model of compressor. These specifications will tell you the correct cut out pressure for your unit.

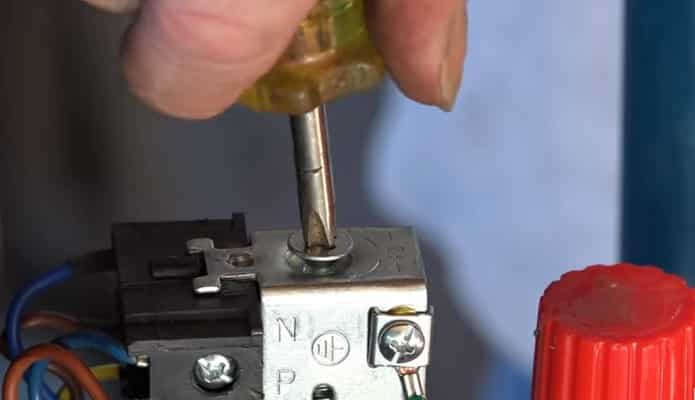

2. Adjust the pressure switch.

The next thing you need to do is adjust the pressure switch. This is usually done by turning a knob or screws on the side of the switch.

3. Test the compressor.

Once you've adjusted the pressure switch, it's important to test the compressor to ensure it's working properly. To do this, turn on the unit and let it run for a few minutes. Then, turn off the unit and check the pressure gauge to see if the pressure is at the correct level.

4. Adjust the cut out pressure.

You'll need to adjust the cut-out pressure if the pressure is too high or too low. This is usually done by turning a knob or screws on the side of the unit.

5. Test the compressor again.

Once you've adjusted the cut out pressure, it's important to test the compressor again to ensure it's working properly. To do this, turn on the unit and let it run for a few minutes. Then, turn off the unit and check the pressure gauge to see if the pressure is at the correct level.

6. Repeat steps 4 and 5

Repeat steps 4 and 5 until the compressor is working properly.

7. Check the pressure regularly.

It's important to check the cut out pressure on your compressor regularly. This will ensure that the unit is working properly and not using more energy than necessary.

The video below shows how to adjust the cut-out pressure on an air compressor:

Adjustable pressure switch for air compressor

If you're looking for an adjustable pressure switch for an air compressor, you're in luck - Amazon has a great selection of products. Just read the reviews and product descriptions carefully to ensure you're getting exactly what you need.

Here are a few options that might work for you:

- Square D by Schneider Electric 9013FHG19J39M1X 9013FHG Air-Compressor Pressure Switch

- Lefoo Air Compressor Switch Pressure Control Switch Valve for Air Compressor Replaces Furnas Square D H4 - Lf10-4h-1-npt1/4-140-175

- Lefoo Quality Air Compressor Pressure Switch Control 95-125 PSI 4 Port w/Unloader LF10-4H-1-NPT1/4-95-125

- Pressure switch for air compressor made by Furnas / Hubbell 69JF7LY2C 95-125 Four port w/ unloader & on/off lever

- Ingersoll-Rand 23474661 Pressure Switch for Single Stage Compressor SS3 And SS5

Factors that can affect the cut out pressure on your air compressor

An air compressor's cut-out pressure is the point at which the compressor will shut off automatically to prevent damage. The manufacturer sets the pressure between 125 and 175 psi (pounds per square inch). Several factors can affect the cut out pressure, including:

1. Inlet air temperature:

The warmer the air that goes into the compressor, the higher the pressure will be.

2. Ambient air pressure:

If the atmospheric pressure is high, it will take more pressure to compress the air, and the cut out pressure will be higher.

3. Air compressor model and size:

Some compressors are designed to operate at higher pressures than others.

4. Discharge piping size and length:

If the discharge pipe is small or long, it will take more pressure to push the air through it, and the cut-out pressure will be higher.

5. Intake filters:

If the air intake filter is dirty or clogged, it will restrict the airflow and the cut out pressure will be higher.

If the cut out pressure is set too low, the compressor will cycle on and off frequently and may be unable to keep up with demand. If the cut out pressure is set too high, the compressor will run for longer periods and may overheat. It is important to set the cut out pressure correctly to prevent damage to the compressor and ensure it operates efficiently.

Tips for maintaining your air compressor so that you don’t have to adjust the cut out pressure very often

If you have an air compressor, chances are you need to adjust the cut out pressure from time to time. Here are seven tips to help you keep your air compressor in good shape and avoid having to adjust the cut out pressure too often:

- Check the air filter regularly and clean or replace it as needed. A dirty air filter can restrict air flow and cause the compressor to overheat.

- Keep the compressor itself clean. Dust and dirt can build up on the compressor over time and cause it to work less efficiently.

- Make sure the cooling fans on the compressor are clean and free of debris. These fins help to dissipate heat and keep the compressor from overloading.

- Check the pressure relief valve to ensure it is functioning properly. This valve helps to release excess pressure and prevent the compressor from overloading.

- Inspect the air tank regularly for signs of corrosion or leaks. These can cause the compressor to lose pressure and may require repairs.

- Keep an eye on the electrical components of the compressor. If any of these components are damaged, it can cause the compressor to overheat or malfunction.

- Have the compressor regularly serviced by a qualified technician. This will help ensure that all the components are in good working order and that the compressor is running at peak efficiency.

Follow these tips, and you should be able to keep your air compressor in good shape for many years.

Final Words

As you can see, there are a few things that you can do to adjust the cut out pressure on your air compressor. By following these tips, you should be able to find the perfect setting for your needs and keep your compressor running smoothly. Have any questions about adjusting the cut-out pressure or troubleshooting other issues with your compressor? Leave us a comment below, and we would be happy to help!