Framing squares are a must-have for any carpenter or do-it-yourselfer. But did you know that framing squares can be used for more than just framing? In this blog post, we will show you how to use your framing square to make accurate measurements and cuts. We'll also show you some handy tips and tricks for using your framing square. So if you're looking to improve your carpentry skills, read on and you might want to take a look at the framing squares available in the market!

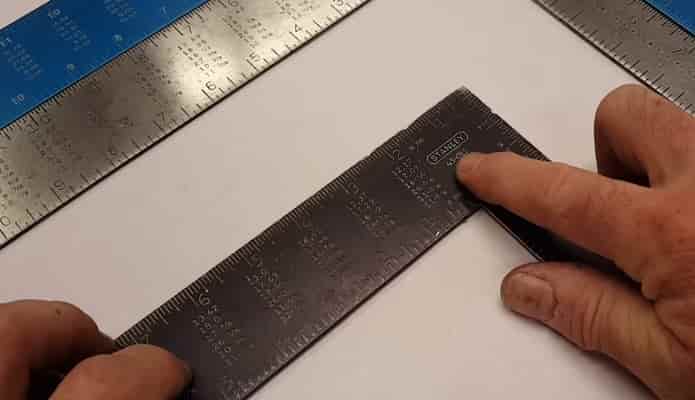

A framing square is a tool used in carpentry to help achieve perfectly perpendicular lines and 90 degree angles. The framing square has a long blade which can be opened up at either end of the tool just like a book. There are 45 degree markings on the blade along with an inch scale.

The perpendicular line for marking cuts between studs or joists can be achieved by placing one side of the framing square against the edge of the wood that is to be cut, then extending it until you have reached your measurement. The distance from where you started at your board edge to where you ended will be exactly how far out from the face of your board or wall that following cuts should be made. You can do this process without measuring for the first cut, and once you have done so for all of your boards or walls, you know that they are perfectly square.

The marking of a perpendicular line by using the framing square is very accurate because unlike a tape measure which can become inaccurate due to stretching of the tape, a framing square does not stretch and therefore will always be true.

It is easy to forget which side was used as the "marking" side when taking more than one measurement from a wood board. In order to avoid confusion there is a small locking mechanism located on the handle of the framing square which allows you to switch between either end being marked side. When measuring from outside edge-to-outside edge it doesn't matter which end your use but if your measuring across the width of a board then it is always best to use the same end for all measurements.

When using a framing square? It is important to have an accurate measurement between two points because if you are off even by the slightest amount, your line will not be plumb (straight up and down) or level (parallel to the ground). To make measuring much easier, many carpenters like to measure out several feet on their tape measures before taking any measurements with their framing squares which ensures that they can make exact marks without having someone hold one side while they mark at exactly where they need to.

Related: Best Air Compressor for Framing Crew Nailer You Can Buy

How to Use Framing Square?

The framing square is a tool used in construction for measuring angles and creating 90 degree corners.

The tool consists of two parts:

- A ruler with an adjustable pivot head so it can be set to an angle, typically 45 degrees or 90 degrees. It usually has inches on one side of the ruler and metric units on the other side.

- A protractor with clip that can be moved along the ruler to measure angles in increments of 1/4° up to 180°.

To set up your framing square properly, place it flat on a work surface with the corner you are building facing upward (handle not pointing down). Locate the exact center of your 2x4 by locating either 12" or 16" from the bottom or top of your board, opposite from the handle. Mark that location with a pencil. Adjust the pivot head so that it points to this mark and tighten it down.

This is important because if the pivot isn't tight, as you're taking measurements throughout your build, you will have inaccurate angles.

To use your square for finding 90 degree corners, line up one corner of your square against two adjacent sides of your 2x4 so there's a right angle at each point where they meet. For example, line up a side edge along a face edge and a back edge along an end edge at both spots where they meet.

You'll notice that on some squares, if you look closely enough near the pivot head, there are two tiny figures that look like an "H" with numbers above it and below it. These numbers indicate the degree marking on your protractor. For instance, if you have a 90 degree corner at the top of one face edge and want to find the corresponding spot for a 90 degree corner on another face edge, line up your square so these two figures are lined up together for both spots where they meet.

Related: How to Use a Framing Nailer? (Step by Step Guide)

Watch the video on how to use framing squares:

How to Use a Framing Square for Angles?

Step 1 - What is the measurement you are looking for? A framing square has an L-shaped frame. It can be turned into any number of positions that will give you different information, depending on what you're looking for. Often, carpenters will use it as a protractor in order to find an accurate angle on their work. This tool is excellent at solving problems like fitting post caps or miter cuts.

Step 2 - Decide on the measurement that you will need for this task. It'll be easier to read angles if they are within 90 degrees, so try to avoid measuring anything which is an acute angle (a small one).

Step 3 - Put your square in position on the corner of your material by lining up one arm of the square with one edge of what you're measuring. There should be two 90 degree angles where both arms meet at a corner, or "close enough" there should be four 90 degree angles for each side combined.

Step 4 - Put your square in position on the other piece of material by lining up one arm of the square with one end; make sure it's overlapping precisely on top of the first piece.

Step 5 - Pick up the tool and check if the angle inside is a perfect 90 degrees. If it's not, you'll need to either adjust your pieces of material or readjust your square until everything lines up properly and you know that you've got an accurate reading for whatever angle you're trying to find out.

How to Use a Framing Square to Cut Rafters?

- Use a framing square to cut rafters when you need specific angles. It has built-in measuring tools that do all of the work for you. It is easy enough that just about anyone can use it. If you plan to build a house or even a simple storage shed, it's a good idea to start getting familiar with this tool now in case you need it later on.

- Measure and mark equal sides of the triangle formed by the top plate and one side stud with a carpenter's pencil from end to end. Do not press too hard when marking lines because your marks should be erased before applying the final coat of mud at final completion. You can also use a chalk line if that is easier for you.

- Position the square on one of its legs with a level line directly under the pencil mark. Draw a plumb cut line down from where you have placed the framing square. You can also use a chalk line or carpenter's pencil to draw this cut after marking it carefully.

- Place your circular saw against the drawn line and cut. Set your blade depth so it will not go through when cutting. If you do happen to hit a nail, then stop immediately and lift the saw until the nail is clear of it, then continue cutting where you left off. Note that this is for safety purposes only. Do not attempt to remove nails if you do not know what you are doing.

- Repeat this process for the remaining two sides of the triangle. This is how your rafter will look like when finished. Each cut should be smooth and clean with no splintering or tear out. There should be a thin wood shaving poking out from the lines made by the framing square. If it looks like there was too much splintering then you probably need to make your blade angle shallower next time. Also, keep in mind that if you're cutting softwood such as pine, then the cut will be cleaner than on hardwood such as oak. You can clamp a straight edge along each cut to make sure they are all the same depth. If you do not have clamps available, then use a screw or nail to attach a straight edge temporarily.

- After you've cut the four equal angles on your rafters, then it's time to mark and cut the birds mouth cuts. Remember that the tip of the birds mouth should be cut at 45 degrees while its bottom has space for laying flat against a rafter. So measure from point A to point B on both ends of each triangle. The distance from Point A to Point B is referred to as "wingspan", which is determined by the height of your roof. The wingspan cut will be the center of your birds mouth cut.

- If you set point A at 8 feet and B at 9 feet then the distance between them is 1 foot which is equal to 12 inches. So, using a framing square, measure 6 inches in from both sides of each triangle. This will mark your location for the bottom half of the cut. To mark the top half, use a straight edge to extend line AB horizontally across each triangle. Mark every other one with an X; this is where you'll make your 45 degree angle cuts with a circular saw or hand saw (do not forget safety precautions when cutting).

- The bottom half of the birds mouth cut is your reference point for leveling. You can use a framing square or any type of level to determine which end needs to be trimmed down lower, then mark this spot with a pencil. This will be done by placing your circular saw against line BC and cutting off anything that exceeds it. Then place your circular saw against line AC and trim off anything that exceeds it.

- With all four sides cut down equally on each rafter triangle, you can now go ahead and lay these triangles flat over top of the side plates to check if they are even with one another. If there is a slight gap on one side, then you need to file it down a little. This can be done by using a rat tail file and going along the bottom cuts.

- Once all four angles are cut down perfectly even with each other, then apply construction adhesive to the back of each rafter triangle and attach them to the top of the side plates. Make sure that there is enough adhesive so that it flows out from underneath. Nail three exterior grade ring shank nails into each angle for extra support.

- Repeat this process until all roof triangles have been attached

- Keep repeating until roof is finished

How to Use a Framing Square to Make Frame?

What you will need:

A framing square and a pencil, tape measure, and a saw.

Steps to take:

- First get your four boards of equal length. Measure the width of the widest piece and mark it on all three pieces with a pencil or pen. Rip down these marks to make them straight lines across all three pieces. Put aside one piece for the back board, one for the bottom, and one for either side. Make sure to measure carefully at this point because if these measurements are off they create the biggest problem later on in construction.

- Take your long board measuring from end to end 52 inches or 1562mm. Mark off every inch/25mm going 25-26-27-28 and so on (or 1-2-3 if you prefer). At the mark 25mm make a small pencil tick. Repeat step 2 until you have reached your desired length.

- Now take your short measuring from end to end 39 inches or 990mm. Mark off every inch/25mm going 28-29-30-31 and so on (or 3-4 if you prefer). At the mark 30mm put a pencil tick as before. You now have 12 marks that are both 40mm apart, but not in a straight line. The longer board has two ticks between each number while the shorter board only has one tick per number, this is because it's easier to cut boards with fewer cuts.

- Use your saw to cut down the small ticks between each number on both boards. Then take one of your side pieces and line it up with the long board. Make sure that the bottom is flat against the table or floor, then place a mark at 5 inches/125mm into each end of the board. These marks are where you will drill holes in order to screw in hinges later.

- Do this for all four pieces of wood by putting them together appropriately to make sure they fit well. Get two screws made for use with hinges for each hinge location (these screws need to be longer than 1 inch/25mm). Drill through your boards, then put in the screws just firmly enough so that they won't fall out but not so hard that you split your board.

- Now take the other side piece and line it up with the short board. Make sure to keep them level, then measure down 5 inches/125mm into each end making pencil marks there as well. Drill holes again in these positions for hinges just like before except drill holes that are long enough to take all four screws without splitting the wood. Try very hard not to split the wood because these splits will make your frame weaker later on when you try to put it together.

- Once both sides are done, turn them over so that they are flat against your table or floor. Put a screw at either side of each hinge mark (you may need more than one screw depending on your wood). Offset the screw from the edge of your board by 1/8th of an inch/3mm to make it easier for you later on.

- Now turn the whole thing over so that you are faced with all four pieces put together as one frame. Line up this frame with a straight line (a piece of string works best because it eliminates human error) and attach using both hinges. You can use glue if you prefer but it's not necessary to do so.

- Your frame is now complete! Put in your canvas, photograph, or whatever else you might want inside and hang it up on your wall! Congratulations 🙂 If there is anything confusing about this article feel free to comment below or send me an email.

What Are Some Other Uses of A Framing Square?

A framing square is a device used by carpenters for measuring and laying out right angles. It consists of two parts, a ruler and a stock, both made from metal or wood. A typical framing square has several holes drilled into its metal edges to receive pins, which can be adjusted from one side of the edge to another with a screwdriver or other tool. Additional holes are located near its ends for holding nails. The most common use of a framing square is to quickly check that walls, floors and roof planes have been constructed plumb (vertical) and level (horizontal).

Here are some other uses:

- The headstock of a framing square can fit into the groove on the edge of certain types of wood to help guide a circular saw.

- The stock of a framing square can be placed on the edge of a piece of lumber or molding and then slid against it while cutting with a power saw. This helps make cuts parallel to the lengthwise side of the lumber.

- The headstock is useful for marking angles on pieces of wood before cutting them at those angles, especially when more than one angle needs to be marked.

- The headstock hole in some squares can be used as a depth gauge for hammering nails into certain types of material without going all the way through, such as concrete blocks.

- Some framing squares have a scale that helps determine roof pitches when building roofs with rafters and trusses.

- The headstock can be used to hold carpentry pencils and marking knives in place while they are being used to mark out the lines of a cut or other workpiece.

- The stock can be inserted into square sockets on either edge of some carpenter's braces to help ensure that the carpenter's square portion is 90 degrees.

- The headstock can be used as an extension handle for some measuring tapes, screwdrivers, paint brushes etc.

- Some framing squares have extensions at opposite ends that enable them to measure distances from center-to-center of joists, rafters and roof beams when laying out rooms, ceilings and roofs using rafters and trusses.

- The headstock can be used to make a small divot in concrete when trying to locate the center of a point on a floor or wall.

Final Words

Congratulations! You've made it to the end of this blog post. I hope you found something useful in here that will help make your framing experience easier and more enjoyable. If not, please let me know what I could have done better - my goal is to provide valuable content for everyone who visits this site. Thank you so much for reading!