Yes, you can sand acrylic plastic. Use fine-grit sandpaper and a gentle touch to avoid scratching. Gradually increase grit for a smoother finish. Clean with a mild detergent and water.

Delving into the world of DIY projects or home renovations often leads to encountering various materials. When it comes to acrylic plastic, the question of whether you can sand it arises. Is it a feasible option for reshaping or refining acrylic surfaces? In this blog post, we'll explore the intricacies of sanding acrylic plastic and unveil the real-life experiences of users who've taken on this challenge. Let's unravel the possibilities and practicalities of sanding acrylic, bringing clarity to a common query in the DIY realm.

It is possible to sand acrylic plastic, but it is a delicate process.

The first step is to lightly sand the surface with fine-grit sandpaper to remove any blemishes or scratches.

Next, use a slightly higher-grit sandpaper to smooth out the surface.

Finally, use fine-grit sandpaper to polish the plastic until it has a glossy finish.

Be careful not to apply too much pressure, as this could cause the plastic to crack or scratch.

What is acrylic plastic?

Acrylic plastic is a type of synthetic plastic created from chemical compounds that are derived from natural gas and oil. It is lightweight yet rigid, making it an ideal material for creating window panes and fixtures.

Acrylic plastic also features excellent optical clarity, meaning that items made with acrylic look clear and colorless; this makes it a popular choice for eyeglasses, skylights, and aquariums.

How is acrylic plastic different from other types of plastic?

Compared to other types of plastic, acrylic has unique properties that make it especially useful in many applications. For instance, its high melting point allows it to be used in items such as car headlights and street lamps that must withstand higher temperatures.

Its resistance to UV radiation also makes it useful for outdoor applications since it can be exposed to sunlight without degrading over time.

Additionally, acrylic plastic is particularly resistant to scratching and chemicals, making it a suitable material for use in items that need a durable finish.

Finally, its ease of fabrication means that items made with acrylic are typically cheaper than those made with other types of plastic. All of these qualities make acrylic an ideal choice for various products.

Sanding Acrylic Plastic: 5 Crucial Purposes

Acrylic plastic is a versatile material prized for its strength and transparency. Sanding helps improve and customize its properties, making it suitable for various applications. Here are five essential purposes of sanding acrylic plastic:

1. Smoothing Out Surfaces

Sanding is a great way to polish and smooth out the surfaces of acrylic plastic, giving it a sleek and professional look. It can remove any rough spots, pores, or jagged edges that may have formed during fabrication. Sanding helps to create an even finish for both handheld and machine-cut acrylic plastic pieces.

2. Achieving Precise Shapes

Acrylic plastic is relatively easy to shape with sandpaper, allowing you to form intricate details in your projects. Sanding also makes it easier to combine two pieces of acrylic plastic without leaving visible seams or gaps. With a little patience and practice, you can achieve precise shapes that would otherwise be difficult with other tools or materials.

3. Adhering Coatings

Sanding provides an ideal surface for adhering coatings, such as paint or varnish. Light sanding helps to remove any residual dust or dirt on the acrylic plastic and provides a rough texture for the coating to stick to. This ensures that your coatings stay in place and last longer over time.

4. Preventing Stress Fractures

Sanding acrylic plastic can also help to prevent stress fractures from forming in the material. Sanding smoothes out the edges of the material, reducing strain caused by sharp corners or jagged edges. This is especially important when working with larger pieces of acrylic plastic, as they are more likely to have uneven surfaces, which could lead to cracks under pressure.

5. Extending the Lifespan

Finally, sanding acrylic plastic can help to extend its lifespan. Sanding helps to prevent dust and dirt build-up on the surface of the plastic, which can weaken it over time. It also reduces the risk of stress fractures due to uneven edges or surfaces, allowing your projects to last longer and look great.

Sanding acrylic plastic is a simple yet effective way to improve its appearance and performance, making it suitable for various applications. By understanding these five key purposes of sanding acrylic plastic, you can master the technique and get better results with your projects.

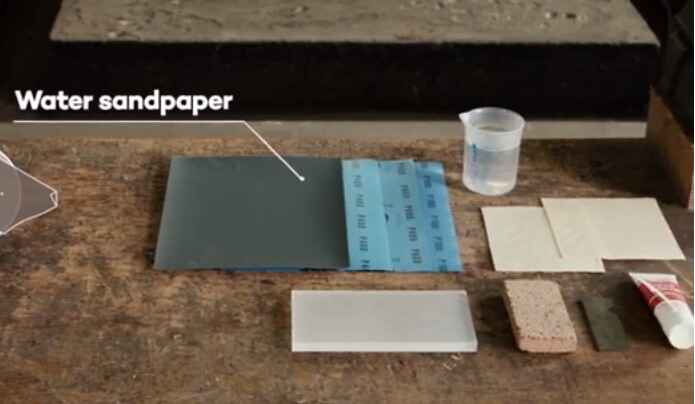

What type of sandpaper should be used to sand acrylic plastic?

Sanding acrylic plastic is an important part of the process for many types of projects. Many people are unsure, however, of what type of sandpaper should be used. The best type of sandpaper to use on acrylic plastic is aluminum oxide paper.

Aluminum oxide paper is a long-lasting, durable sandpaper perfect for hard surfaces like acrylic plastic. It is also resistant to clogging, so you won't have to worry about the sandpaper loading up and becoming ineffective.

When sanding acrylic plastic, use an extra-fine grit of aluminum oxide paper. The extra-fine grit will give you a smoother finish and make it easier to do the job without damaging the plastic.

Additionally, use a sanding block or backing pad when sanding acrylic plastic. This will help keep the paper flat and ensure an even finish. It will also help you apply the right amount of pressure to prevent over-sanding.

When shopping for aluminum oxide sandpaper, be sure to look for a paper that is specifically designed for use on acrylic plastic. Many types of sandpaper are available in different grits, but not all are suitable for acrylic plastic. You can get a smooth finish without damaging the plastic with the right type of paper.

How to sand acrylic plastic?

Sanding acrylic plastic can be tricky, but with the right technique and tools, you can achieve a professional finish. This step-by-step guide will discuss the best way to sand acrylic plastic for a neat and smooth result.

Step 1: Wear Proper Safety Gear

Always wear safety goggles, a dust mask, and gloves when sanding acrylic plastic to protect yourself from dust and debris.

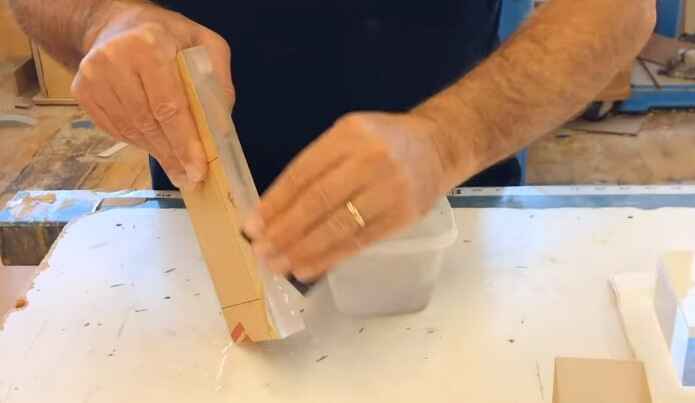

Step 2: Prepare the Surface

Start by wiping down the surface of the acrylic plastic with a clean cloth to remove any dirt or debris.

Step 3: Sand with Coarse Grit Paper

Start sanding with 120-grit sandpaper to remove scratches, then use 200-grit sandpaper to smooth the surface. Use a circular motion while sanding to avoid leaving deep gouges in the plastic.

Step 4: Apply Fine Grit Paper

When you have finished using the coarse-grit sandpaper, switch to a finer grade of sandpaper, such as 320-grit, and continue to use circular motions. This will remove any remaining scratches and smooth out the surface even more.

Step 5: Sand with Extra Fine Grit Paper

Finally, finish by sanding with extra fine grit paper, such as 400 or 600 grit, for a polished look. Once again, use circular motions when sanding to avoid leaving deep gouges.

Step 6: Polish The Surface

Once all the sanding is complete, you can apply a polishing compound to the surface to give it a mirror-like shine. If you do this, apply the compound in circular motions.

Step 7: Wipe Away Excess Dust

When you're finished, use a clean cloth to wipe away dust and debris. You can also use a vacuum cleaner with an appropriate attachment to remove the dust particles.

Step 8: Clean The Surface

Finally, give the acrylic plastic one last cleaning by wiping it down with a damp cloth and then allowing it to dry completely before using it.

And there you have it! You've now completed sanding your acrylic plastic. Ensure proper safety precautions when working with this material, as its fumes can be hazardous if inhaled or ingested. Be safe, have fun, and enjoy your newly sanded project!

Properties of acrylic plastic that affect sandability

Sanding acrylic plastic is essential to creating a smooth, finished product. To do this effectively, it's important to understand the properties of acrylic plastic that affect how it sands. Here are five fundamental properties of acrylic plastic that influence sandability and provide tips for getting the best results.

1. Composition

Acrylic plastic comprises polymethyl methacrylate (PMMA) and other monomers, which are joined together to form long chains. The composition of acrylic plastic directly impacts its sandability: the higher the PMMA content, the better it sands. Additionally, polymers cross-linked with additional monomers produce a harder plastic, resulting in better sanding.

2. Hardness

The hardness of acrylic plastic affects its sandability. Generally speaking, softer plastics are easier to sand than harder ones; however, they are too soft and won't hold up to the abrasive action of sanding. Acrylics with a hardness rating between 60 and 80 on the Rockwell scale are best for sanding.

3. Porosity

Porosity is a measure of how much air can pass through acrylic plastic. Acrylics with low porosity levels will hold up better to the abrasive action of sanding, as there's less risk of breaking down. Although some porosity is desirable for creating a smooth finish, too much can lead to poor sandability.

4. Thermal Stability

The thermal stability of acrylic plastic also affects its sandability. If acrylic isn't thermally stable, it won't withstand the heat generated by sanding without melting or becoming brittle and flaking off. Look for acrylics with a high thermal stability rating to ensure good results.

5. Surface Finish

The surface finish of acrylic plastic is vital for sanding as well. Smooth surfaces are easier to sand than rough ones and will result in a better-finished product. Acrylic plastics with a glossy or matte finish are best for sanding, as they provide the perfect balance between grip and smoothness.

By understanding these five properties, you can choose the right acrylic plastic for your project and get the best sanding results. To get started, experiment with different types of acrylics until you find one that works well with your specific needs and preferences.

With the proper knowledge and materials, you'll be able to create beautiful products that look polished and professional every time.

What are the benefits of sanding acrylic plastic?

Sanding acrylic plastic is a useful and effective way to get the desired results for any project. It can smooth, shape, or polish surfaces and edges of all plastic materials. The benefits of sanding acrylic plastic include improved surface finish, better adhesion, reduced wear-and-tear, lessened risk of damage, and improved overall aesthetics.

1. Improved Surface Finish

Sanding acrylic plastic helps create a smoother surface finish by removing excess material, such as burrs or ridges, that may have been left behind by machining or other fabrication processes.

This process also eliminates microscopic protrusions, which cause light reflection leading to an uneven surface texture. With the right tools and techniques, it's possible to achieve an optimal finish with a consistent level of surface gloss.

2. Better Adhesion

Sanding acrylic plastic helps to create a better surface for adhesives and paints to bond onto. By removing any irregularities, the sanded plastic will provide an even foundation supporting strong adhesive bonds without the risk of air or dirt pockets forming beneath the material.

This makes it easier to join components together or attach other materials reliably and securely.

3. Reduced Wear-and-Tear

When appropriately sanded, acrylic plastic becomes more robust and resistant to wear and tear caused by everyday use, such as friction or impact. The improved surface finish creates a harder exterior which is less likely to become scratched, dented, cracked, or split when exposed to various levels of force.

This makes sanded plastic ideal for use in aerospace engineering and automotive manufacturing industries, where materials are expected to withstand extreme temperatures, pressures, or vibrations.

4. Lessened Risk of Damage

When sanded, acrylic plastic becomes less brittle and prone to breakage due to temperature changes or other environmental factors.

Its improved surface finish provides greater elasticity and strength, which helps protect the material from cracking under pressure. This reduces the risk of damage caused by external forces that could otherwise cause permanent deformities.

5. Improved Overall Aesthetics

Sanding acrylic plastic provides clarity and smoothness that can drastically improve its overall aesthetics compared with untreated materials.

This process also allows intricate patterns and shapes to be carved into the material, creating unique visual effects and textures. With proper sanding techniques, it is possible to achieve a glossy finish that can further enhance this material's natural beauty.

Overall, sanding acrylic plastic offers a range of benefits that make it an ideal choice for any project

Tips for achieving a smooth finish on acrylic plastic

Acrylic plastic is a popular material that can be used in a wide range of applications. It has properties that make it ideal for signs, windows, display cases, and more. To get the best finish on your acrylic project, there are some tips you should keep in mind. Here are five tips to help you achieve a smooth finish on acrylic plastic:

1. Sand the Edges Smoothly

The first step to achieving a smooth finish on acrylic is to sand the edges. Use an electric sander and fine-grit sandpaper to carefully sand away any ridges or sharp edges that could interfere with the final result. Make sure to move in one direction, and use a dust mask and safety glasses when sanding.

2. Use a Polishing Compound

A polishing compound designed for acrylic plastic can help you achieve a perfect finish. Apply the compound in an even layer using a clean, soft cloth and work it into the surface until it is shiny. This will bring out the plastic's clarity and eliminate any small scratches or blemishes.

3. Buff with Soft Cloth

Once the polishing compound has been applied, buff the surface with a soft cloth to give it an extra shine. Make sure to move in one direction along the length of the material, taking care not to leave streaks or swirls behind. Be gentle! Too much force can scratch the plastic.

4. Use a High-Speed Buffer

For an even higher level of shine, use a high-speed buffer with a buffing pad made for plastics. This will help remove any remaining imperfections or scratches and create a mirror-like finish for your project. Ensure you wear protective gear such as safety glasses and gloves when using the buffer.

5. Spray on Wax

Finally, spray on a clear wax or sealant layer to protect the acrylic and maintain its smooth, polished finish. Be sure to apply it in thin coats to avoid build-up and allow plenty of time between coats for drying so that the finish is even. This extra step will help keep your project looking great and lasting for years to come.

Following these five tips, you can achieve a smooth finish on your acrylic project. When working with acrylic plastic, it's important to remember that the key is patience and attention to detail. The time you take to sand, polish, and buff will be worth it when you see the result.

Final Words

After reading this blog post, you will feel better informed about sanding acrylic plastic. Sanding acrylic plastic is possible if you take the right precautions, use the right equipment, and apply the right techniques. Use fine-grit sandpaper and protect your work area with either newspaper or a dust mask.

Additionally, it may be beneficial to practice on a spare piece of acrylic first before tackling larger projects or pieces of art. If you have any further questions regarding how to sand acrylic plastic, it's best to seek expert advice for reliable information.

With some preparation and know-how, sanding acrylic plastic can become one of your favorite creative activities.