Various hose clamps, like worm gear, spring, and T-bolt, cater to different needs. From securing radiator hoses to handling heavy-duty applications, these 21 types provide versatile solutions for various industries and DIY projects.

New to the world of hose clamps and feeling a bit overwhelmed by the variety available? Don't fret! Navigating the realm of hose clamps is easier than you think. In this beginner-friendly guide, we'll demystify the subject by introducing you to 21 different types of hose clamps and shedding light on their unique uses. Whether you're a DIY enthusiast or just starting to explore the world of tools, this post will equip you with the essential knowledge to choose the right hose clamp for your needs. Let's dive in!

There are a few things to consider when choosing the best hose clamps for your needs. Here are seven factors to keep in mind:

1. Type of material:

Hose clamps are made from different materials, including stainless steel, zinc-plated steel, and plastic. Consider the type of material compatible with the hose material and the type of environment in which the hose will be used.

2. Hose diameter:

It is essential to choose a hose clamp that is sized appropriately for the diameter of the hose. If the clamp is too small, it may not be able to provide a secure seal. If the clamp is too large, it may be challenging to install or remove.

3. Band width:

The width of the band is another crucial factor to consider. A wider band will provide more surface area for gripping and may be more durable than a narrower band.

4. Screw type:

Hose clamps typically have a Phillips head or slotted screws. Consider which type of screw will be easiest to work with, given the tools that you have available.

5. Installation method:

Hose clamps can be installed using various ways, including hand tightening, torque wrench, and pneumatic tool. Consider which installation method will be most convenient for you.

6. Removal method:

It is essential to consider how the hose clamp will be removed when it is time to replace the hose or make repairs. Some clamps can be removed by hand, while others require special tools.

7. Price:

Hose clamps are available at various price points. Consider your budget when choosing a hose clamp.

Related: Check out different types of pipe clamps and their uses for more information

Different types of hose clamps and their uses

Hose clamps are used to secure hoses onto fittings to prevent leaks and ensure a tight connection. There are several types of hose clamps available, each with its own design and specific uses. Here are some common types of hose clamps and their uses:

1. 1 ear hose clamps

A 1-ear hose clamp is a type of clamp with a single ear. It is typically used to clamp hoses with an outside diameter of 1 inch or less.

Some common uses for 1 ear hose clamps include:

- Securing hoses on engines

- Connecting hoses to pipe fittings

- Retaining wires in electrical conduit

- Joining metal plates together

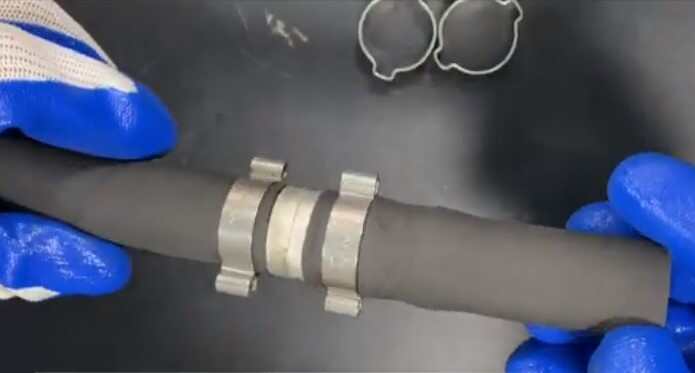

2. 2 ear hose clamps

A 2-ear hose clamp is a type of hose clamp with two ears or tabs that can tighten the clamp around a hose.

The two ears make it easier to tighten the clamp around the hose. This is especially helpful if the hose is in a difficult-to-reach place. The clamps are also adjustable, which means that they can be tightened or loosened to fit different sizes of hoses.

The 2 ear hose clamps are commonly used in automotive applications, such as when a car's radiator needs to be refilled with coolant. The clamps can also be used for other applications, such as plumbing and hvac work.

3. Adjustable hose clamps

An adjustable hose clamp, also known as a cinch clamp, is a fastener used to secure hoses and other cylindrical objects. The adjustable hose clamp consists of two metal strips placed around the object to be fastened and tightened by a screw or bolt.

The adjustable hose clamp has many applications, including HVAC, automotive repair, plumbing, and manufacturing. It is advantageous when the object to be secured is not a standard size or when there is no access to the back side of the object.

4. Bridge (or spiral) clamps

Bridge clamps, also known as spiral clamps, are a type of clamp that is used to connect two pieces of metal. They can be used for various purposes, including repairing metal pipes, joining pieces of metal together, and creating structures out of metal.

Bridge clamps have two parts: the clamp and the screw. A clamp attaches to the piece of metal that needs to be connected, while a screw attaches to the other piece. Bridge clamps can be either opened or closed. Open bridge clamps have a gap between the two pieces of metal that need to be connected, while closed bridge clamps have no gap.

5. Double-wire clamps

Double-wire clamps are a type of clamp that is used to secure two wires or cables together. They are usually made from steel and have two wire loops on one end that can be secured around the two wires or cables.

Double-wire clamps are commonly used in electrical wiring, automotive repair, and plumbing. They can be used to hold wires or cables together while being soldered, create a temporary electrical connection, or secure a pipe to a fitting.

6. Embossed hose clamps

Embossed hose clamps are a type of clamp that is used to secure hoses in place. They are typically made from metal and have an embossed design on the surface. This design helps to keep the hose in place and prevents it from slipping out of the clamp.

Embossed hose clamps are commonly used in automotive applications, where they are used to secure hoses that carry engine coolant or oil. They can also be used in other applications, such as plumbing or construction.

7. Heavy-duty hose clamps

Heavy-duty hose clamps are a type of clamp that is used to secure hoses and tubes. They are typically steel or brass and are designed to withstand high-pressure levels.

Heavy-duty hose clamps have a variety of applications, including:

- securing hoses on engines

- securing fuel lines

- securing water lines

- repairing leaks in hoses or tubes.

8. Marman clamps

A Marman clamp is a fastener used to join two pieces of tubing or other cylindrical objects. The clamps are squeeze-fitted around the two objects and then secured with bolts or screws.

Marman clamps have a variety of uses, including:

- Joining sections of tubing together in a fluid system

- Securing hoses and cables in place

- Mounting cylinders or other objects to a frame or panel

They are prevalent in the aerospace industry, where their ability to join cylindrical objects tightly and securely is essential.

9. O-clips

O-clips are a type of fastener that is used to hold two or more pieces of material together. They are created by taking a metal ring and then clipping it onto two pieces. O-clips have many applications, including automotive, construction, and marine industries.

10. Perforated band clamps with separated housings

Perforated Band clamps with separated housings are used to join two pieces of metal together. They are often used in construction or engineering projects and can be made from various materials, including steel and aluminum.

The perforated band clamps with separated housings work by using a series of bolts to tighten the clamp around the two pieces of metal. This creates a tight seal that joins the two pieces together. The housing on either side helps keep the clamp in place and protects the bolts from loose.

11. Perforated band clamps with tilting housing

Perforated band clamps with tilting housing are designed to provide a secure connection between two pieces of metal while also tilting the housing to keep the clamp aligned. This clamp is ideal for heavy-duty applications where a high level of tension is required.

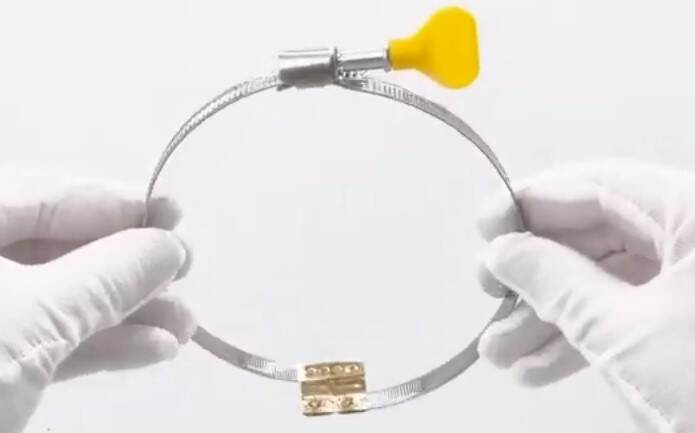

12. Quick Release hose clamps

A quick-release hose clamp is a type of clamp used to secure hoses, tubing, or cables. It features a small lever that can be depressed with one hand to release the clamp so that the hose can be quickly disconnected. Quick-release hose clamps are often used in automotive and industrial applications where a fast release is necessary. For example, they may be used on fuel, hydraulics, or airlines. Quick-release hose clamps are also commonly used in plumbing and HVAC applications.

13. Ratchet clamps

Ratchet clamps are clamps that use a ratcheting mechanism to tighten the clamp around an object. This allows more torque to be applied, making them ideal for heavy-duty applications.

Ratchet clamps are commonly used in metalworking and woodworking, where they can be used to hold objects in place while being cut or drilled. They can also be used for welding, fabricating, and many other industrial applications.

14. Screw clamps

Screw clamps are a clamp that uses a screw to apply pressure to two pieces of wood, metal, or other materials. This type of clamp is often used in carpentry and metalworking. It can be used to hold two pieces of material together while they are being glued, screwed, or nailed. The screw clamp is also commonly used in automotive and machine shops to hold parts in place while being worked on.

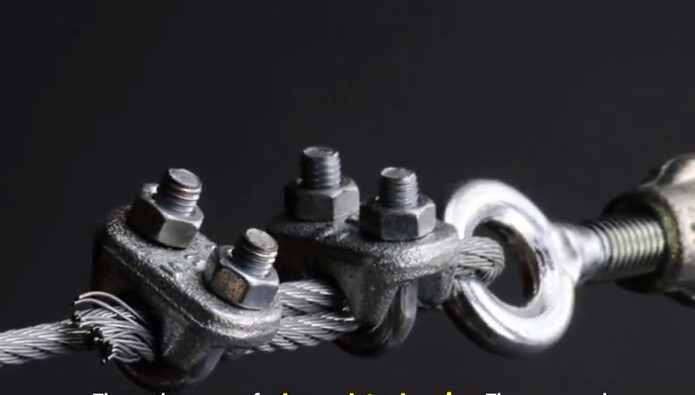

15. Wire clamps

Single-wire clamps are devices used to attach a single wire to a connector or another object. They have a variety of applications, including electrical wiring, telecommunications, and medical equipment.

One everyday use for single-wire clamps is in electrical wiring. They can attach wires to connectors or other objects, such as switches and sockets. This allows for a secure connection and helps prevent the wire from coming loose.

Another common use for single-wire clamps is in telecommunications. They can connect cables to other objects, such as connectors and antennae. This allows for a secure connection and helps keep the cables organized and tidy.

16. Solid metal band clamps with buckles

A solid metal band clamp with buckles is a clamp that uses a metal band and buckles to secure an object. It is often used in woodworking or metalworking projects. The clamp can be tightened to secure the object and be released to adjust its position.

17. Spring hose clamps

Spring hose clamps are used to clamp hoses and tubes. They have a spring-loaded action that provides a tighter grip as the clamp is tightened. This makes them ideal for use in applications with a high-pressure level.

They are also commonly used in automotive applications, as well as in manufacturing and other industrial settings where pipes and hoses need to be tightly secured. Spring hose clamps can also be found in many home improvement stores, often used to attach garden hoses to faucets.

18. Step-less 1 ear hose clamps

Step-less 1 ear hose clamps are a type of clamp that is used to secure tubing or hoses. It has a unique design that allows it to be tightened without using tools and quickly released using just one hand.

Step-less 1 ear hose clamps are ideal for various automotive, industrial, and agricultural applications. They are also popular among DIY enthusiasts and home builders. Some of the key benefits of using Step less 1 ear hose clamps include:

19. T-bolt band clamps

A T-bolt band clamp is a type of band clamp that uses a threaded bolt to tighten the clamp around whatever it is securing. This band clamp is ideal for heavy-duty applications, as it can apply more pressure than other band clamps.

Some common uses for T-bolt band clamps include securing piping, hoses, and cables in industrial settings. They can also be used in automotive or construction applications. Thanks to their high tension level, T-bolt band clamps are perfect for jobs requiring a lot of force.

20. V-band clamps

A V-band clamp is a type of clamp that is used to join and hold together two metal tubes or pipes. It is usually a U-shaped, stainless steel band with two threaded bolts on either side. The clamps are tightened against the tubes or pipes to hold them together.

V-band clamps are commonly used in exhaust systems, where they are used to connect and fasten together the sections of the exhaust pipe. They are also sometimes used in air conditioning and refrigeration systems.

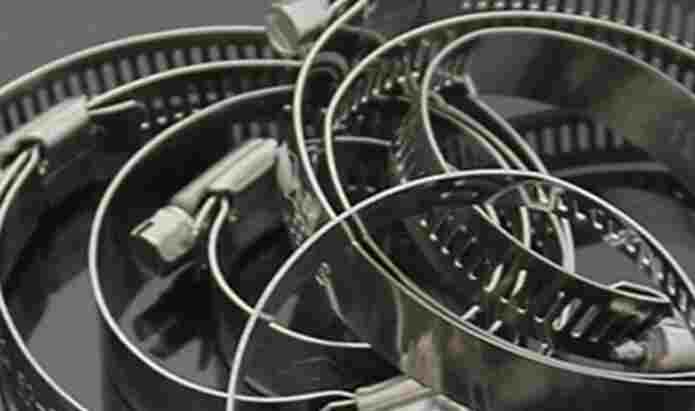

21. Worm drive hose clamps

Worm-drive hose clamps are a type of clamp that uses a gear to tighten the clamp around the hose. They are used when there is limited space to install a clamp.

The primary use for worm drive hose clamps is in situations where there is not enough room for a regular screwdriver or socket wrench to tighten the clamp. The worm drive hose clamp gear can tighten it even in tight spaces. They are also popular because they are less likely to damage the hose than other clamps.

Related: Discover the uses and types of lab clamps if you find them interesting

Final Words

Many types of hose clamps are available on the market, each with its specific purposes. When choosing a hose clamp, make sure to select one that is designed for the application you have in mind. With so many different options available, there is sure to be a hose clamp out there that meets your needs perfectly. Have you used hose clamps before? What type did you use, and was it effective? Let me know in the comments below.